An energy-saving device for directional solidification and impurity removal of metallurgical silicon

A directional solidification and energy-saving device technology, applied in silicon compounds, non-metallic elements, inorganic chemistry, etc., can solve the problems of long production cycle, high equipment cost, and silicon leakage accidents of quartz ceramics, so as to reduce the amount of auxiliary materials and improve repeatability. The number of times of use and the effect of strong heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

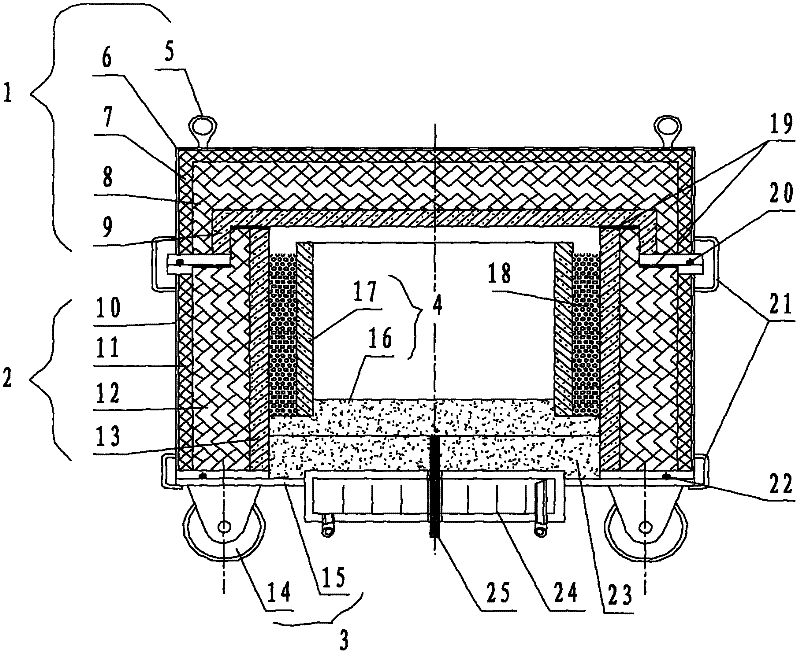

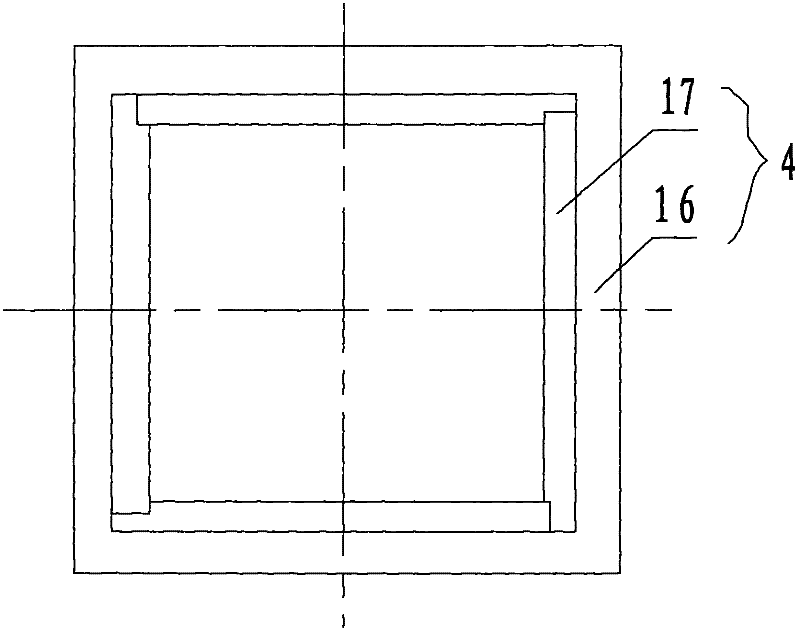

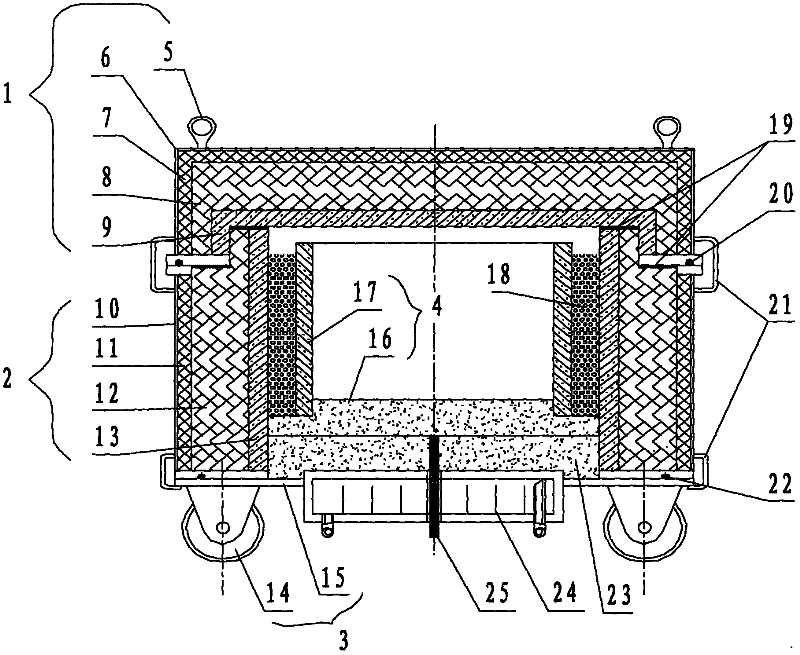

[0021] Such as figure 1 and figure 2 As shown, the device is a rectangular body, including an upper insulation cover (1), a middle insulation cover (2) and a lower floor rail frame (3), a composite mold (4), a heat conducting plate (23) and a water-cooled copper plate (24 ), the water-cooled copper plate (24) is located in the middle of the lower floor track frame (3), the heat conduction plate (23) is located on the top of the water-cooled copper plate (24), and the composite mold (4) is arranged on the heat conduction plate (23) In the upper part, silicon carbide particles (18) are filled around the composite mold (4) for support and heat preservation, and a sealing ring (20) is arranged between the upper heat preservation cover (1) and the middle heat preservation cover (2).

[0022] The upper insulation cover (1) includes a suspension ring (5), a steel furnace cover (6), a polycrystalline ceramic fiber layer (7), a potassium hexatitanate whisker layer (8), and a corundum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com