Method for preparing chromium hydroxide from chromium slag to co-produce mixed hydroxide of barium chloride, calcium, magnesium and aluminum

A technology of chromium hydroxide and hydroxide, applied in the direction of calcium/strontium/barium oxide/hydroxide, chromium compound, magnesium hydroxide, etc., can solve the problem of difficult transportation, insufficient use of valuable elements, and the preparation of hydrogen Solve problems such as chromium oxide, achieve pollution reduction, significant social and economic benefits, simple process and production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] specific implementation

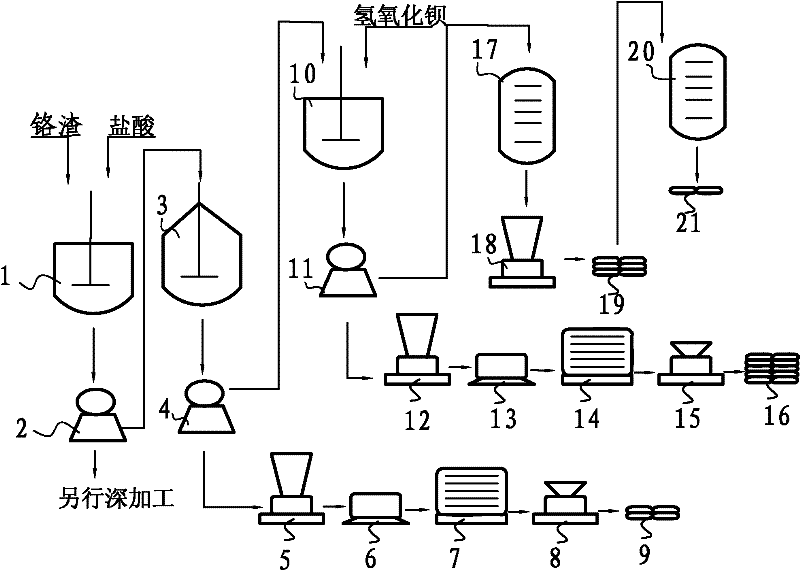

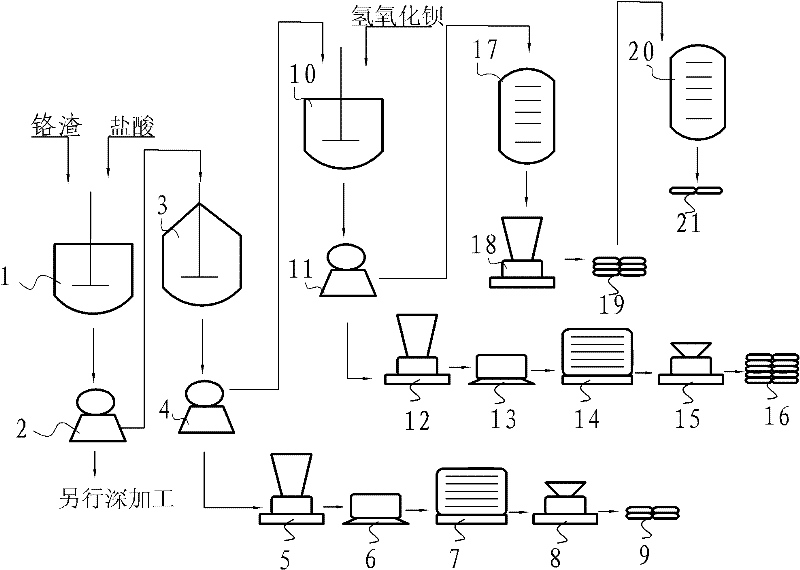

[0045] A method for preparing chromium hydroxide from chromium slag to co-produce mixed hydroxides of barium chloride, calcium, magnesium and aluminum, comprising the following preparation steps:

[0046] Step A, the chromium slag 1000Kg (wherein, trivalent chromium is 30Kg, hexavalent chromium is 10Kg, calcium oxide is 300Kg, magnesium oxide is 250Kg, aluminum oxide is 60Kg) is packed into the first resistant to hydrochloric acid by step A, chromium slag 1000Kg (wherein, trivalent chromium is 30Kg, and aluminum oxide is 60Kg) The corrosion reactor 1 is fully stirred, wherein the chromium slag is subjected to acidolysis reaction with converted trivalent chromium and hexavalent chromium and hydrochloric acid according to the pure mass ratio of 1:0.47, and the reaction obtains chromium chloride, calcium chloride, The mixture I of magnesium chloride, aluminum chloride; Hydrochloric acid is the hydrochloric acid solution that volume percentage conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com