Aluminate phosphor, method for producing same, and light-emitting element

A manufacturing method and aluminate technology, applied in electrical components, luminescent materials, electrical solid devices, etc., can solve problems such as low quantum yield and luminous intensity of phosphors, and achieve the effect of high luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

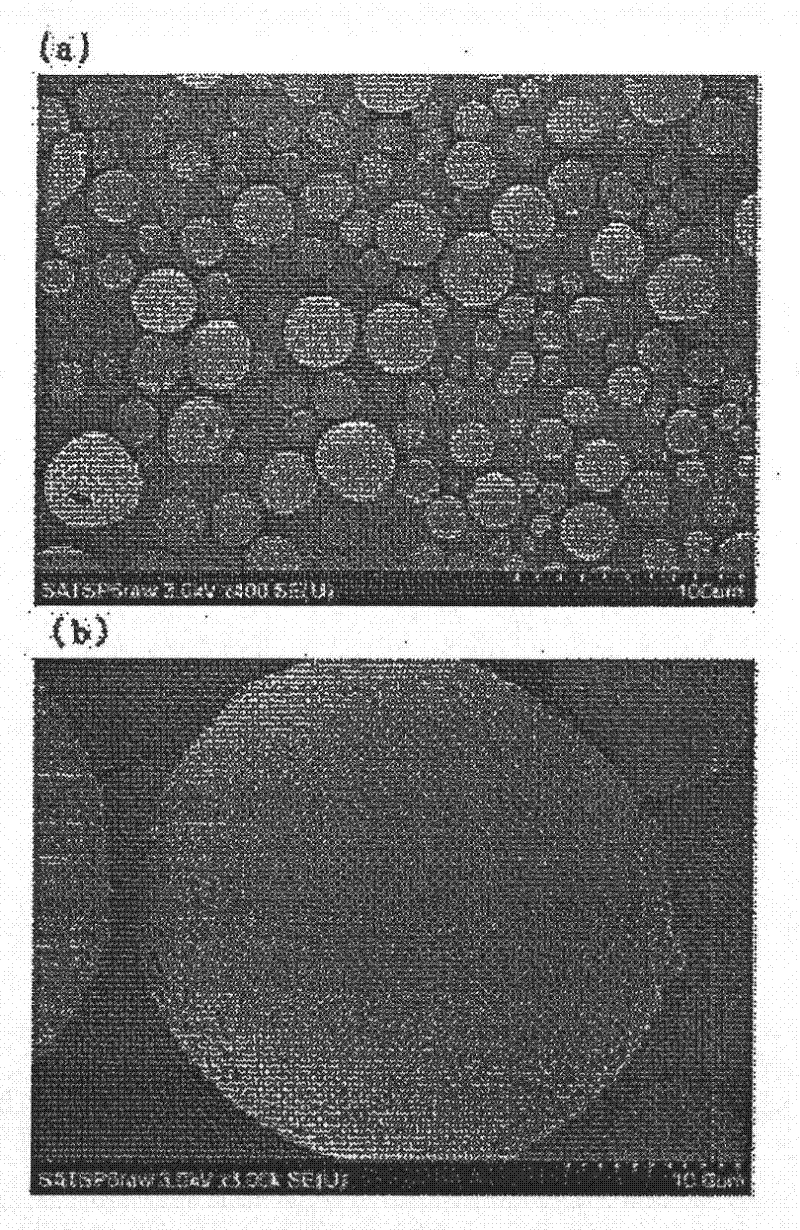

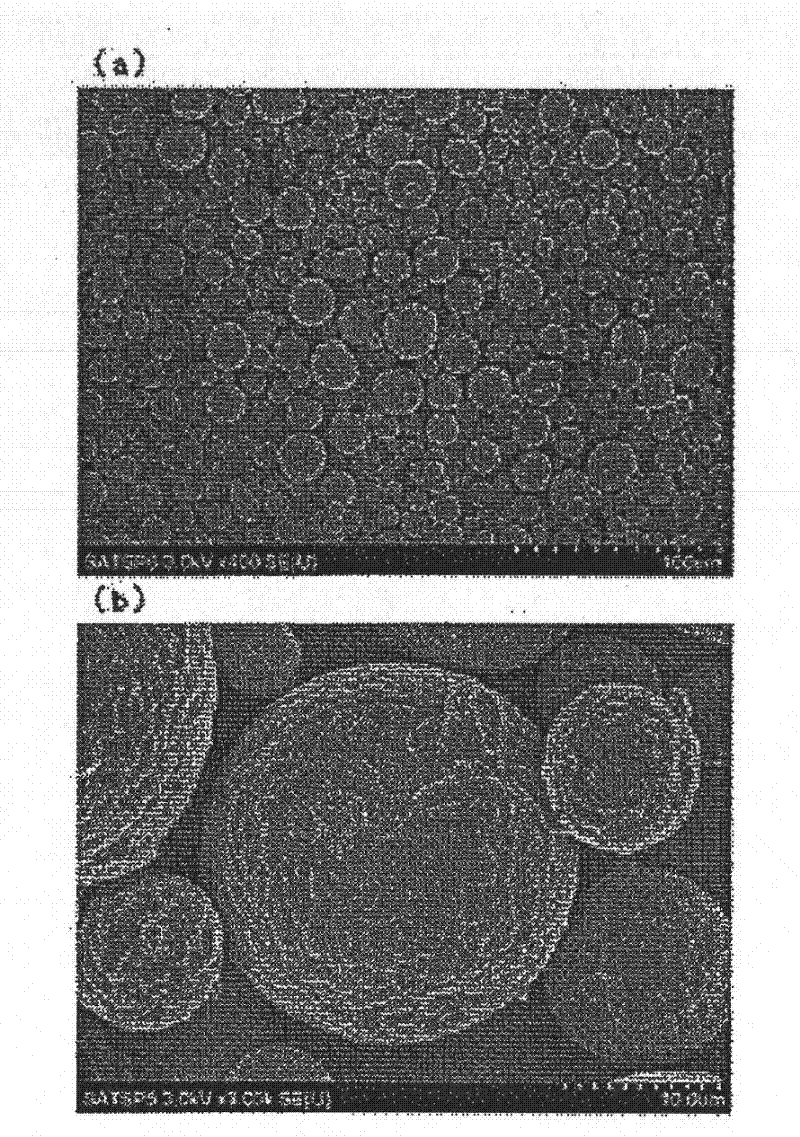

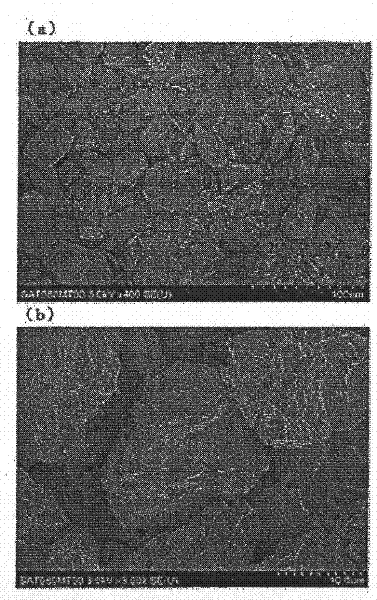

Image

Examples

Embodiment 1

[0076] (1) Uniform slurry preparation process;

[0077] The molar ratio of Sr:Al:Eu is 0.9:2.12:0.1, i.e. (Sr+Eu) / Al=0.47, Eu / (Sr+Eu)=0.1, weigh strontium carbonate (average particle size 0.83μm), alumina (γ-alumina; average particle size 11.8μm, specific surface area 150m 2 / g) and europium oxide (average particle size: 3.66 μm), and put them into a ball mill. Water and a dispersant (Pois 2100, manufactured by Kao Corporation) were added to a ball mill to prepare a mixed liquid having a solid content concentration of 25%. The concentration of dispersant is 4%.

[0078] Zirconia balls with a diameter of 1.0 mm were added to the ball mill, and mixed and pulverized by a wet method for 15 hours. When the average particle diameter of the solid content of the slurry after mixing and pulverization was measured by the light scattering method, it was 0.12 micrometers.

[0079] (2) spray drying process (drying process);

[0080] Next, the mixed liquid was supplied at a supply rate...

Embodiment 2

[0087] In the (one) homogeneously mixed slurry preparation process of embodiment 1, except that the charge molar ratio is set as (Sr+Eu) / Al=0.5, Eu / (Sr+Eu)=0.05, all the other are the same as embodiment 1 Same operation, obtain aluminate phosphor (SrAl 2 o 4 : Eu). As a result of X-ray diffraction measurement of the obtained aluminate phosphor, it was confirmed that strontium aluminate having a tridymite structure was obtained.

Embodiment 3

[0089] In the (one) homogeneously mixed slurry preparation process of embodiment 1, except that the charge molar ratio is set as (Sr+Eu) / Al=0.45, Eu / (Sr+Eu)=0.05, all the other are the same as embodiment 1 Same operation, obtain aluminate phosphor (SrAl 2 o 4 : Eu). As a result of X-ray diffraction measurement of the obtained aluminate phosphor, it was confirmed that strontium aluminate having a tridymite structure was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com