Transparent conductive laminate and transparent touch panel using the same

A technology of transparent conductivity and transparent conductive layer, which is applied to the conductive layer on the insulating carrier, the parts of the color TV, the parts of the TV system, etc., and can solve the problem of damage to the transparent conductive layer of the movable electrode substrate, flying debris, display Problems such as poor visibility, achieve wide-angle and image clarity, reduce the frequency of replacement, and achieve the effect of large image clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0162] Hereinafter, examples are given to illustrate the present invention in more detail, but the present invention is not limited by these examples. It should be noted that, in the Examples, "parts" and "%" are mass references unless otherwise specified. In addition, various measurements in Examples were performed as follows.

[0163]

[0164] The measurement was performed using a probe-type height difference meter DEKTAK3 manufactured by Sloan Company. Measurement was performed in accordance with JIS B0601-1994 edition.

[0165]

[0166] Measurement was performed using Surfcorder SE-3400 manufactured by Kosaka Laboratories. Measurement was performed in accordance with JIS B0601-1982 edition.

[0167]

[0168] The measurement was performed using a stylus type film thickness meter Alphastec manufactured by Anritsu Electric Co., Ltd.

[0169]

[0170] The measurement was performed using a haze meter (MDH2000) manufactured by Nippon Denshoku Co., Ltd.

[0171]

...

Embodiment A and comparative example A

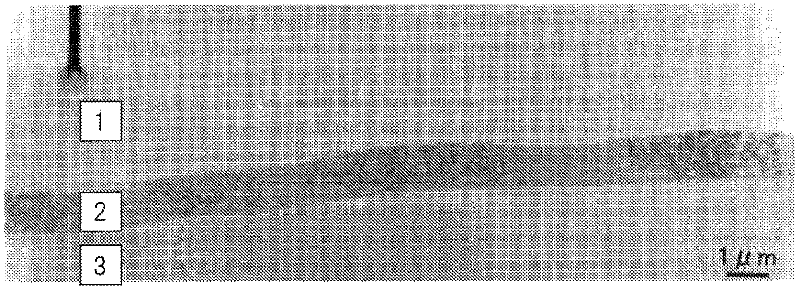

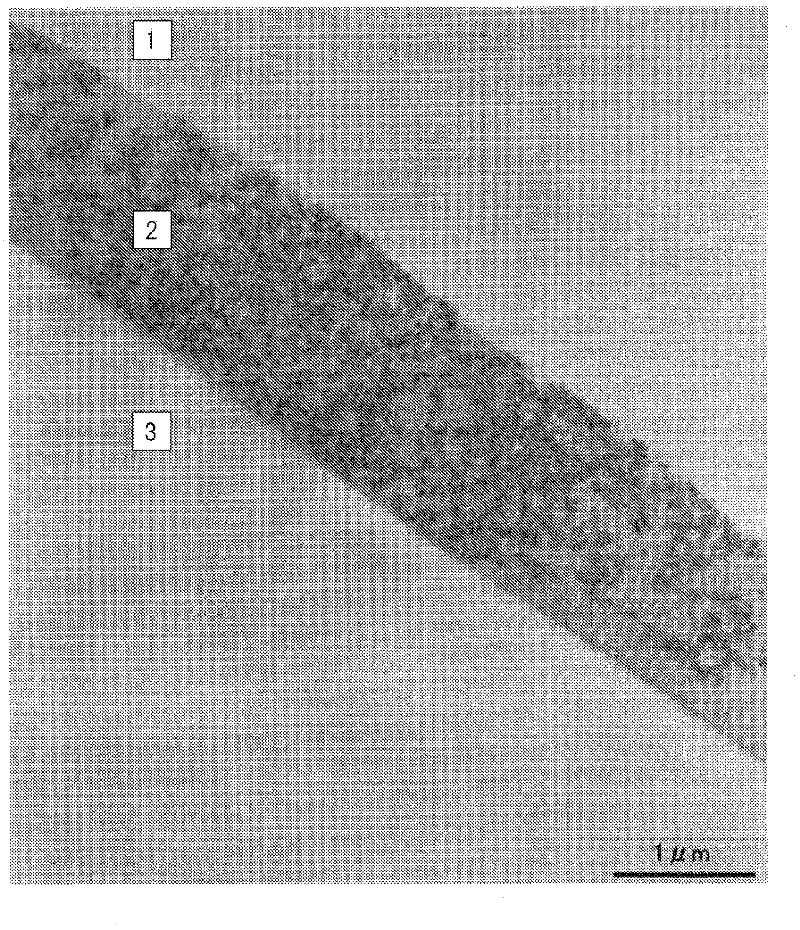

[0182] It will be shown below that by mixing metal oxide ultrafine particles and metal fluoride ultrafine particles in a specific ratio, a weak association state is formed in the cured resin layer, thereby forming a desired concavo-convex shape.

Embodiment A1

[0184] Using a polycarbonate film (manufactured by Teijin Chemicals Co., Ltd., C110-100) (PC) as a transparent organic polymer substrate, a coating liquid R having the following composition was applied on one side with a ring bar coater A , after heating and drying at 40°C for 1 minute, irradiate with a UV lamp at 120mW / cm 2 、400mJ / cm 2 UV rays form a cured resin layer with a film thickness of about 1.5 μm and a concave-convex surface.

[0185] Coating solution R A composition of

[0186] Quadrifunctional acrylate: 100 parts by mass of "ARONIX" M-405 (manufactured by Toagosei Co., Ltd.)

[0187] Metal oxide ultrafine particle dispersion: 80 parts by mass (8 parts by mass in terms of solid content, SiO manufactured by CI Chemicals Co., Ltd. 2 10% by mass isopropanol dispersion of ultrafine particles, primary average particle size of ultrafine particles is 30nm)

[0188] Metal fluoride ultrafine particle dispersion: 20 parts by mass (4 parts by mass in terms of solid conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com