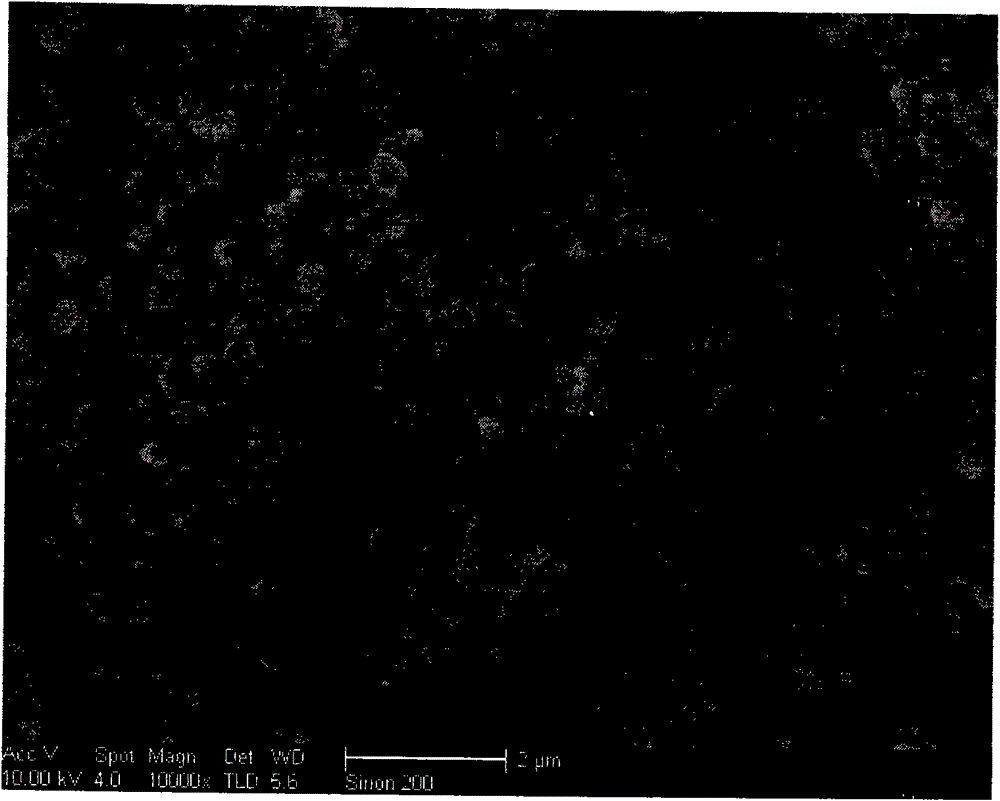

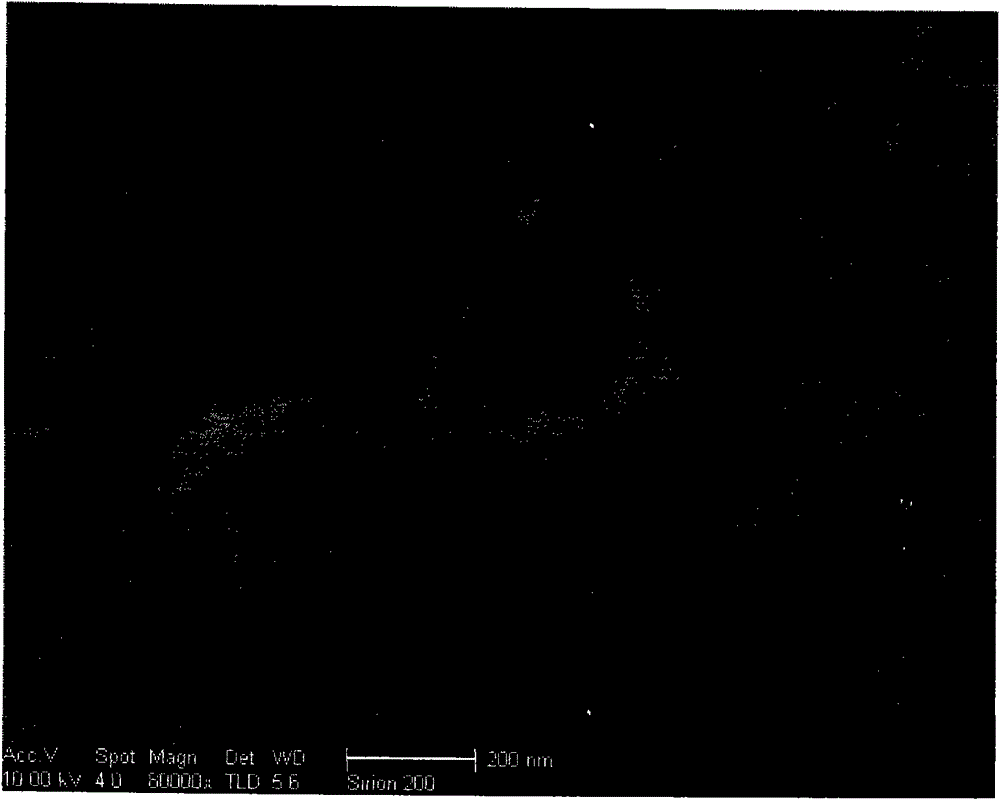

Preparation method for hollow silk cocoon-like CuO nanomaterial

A technology of nanomaterials and silkworm cocoons, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problem of long reaction time (several hours or tens of hours, large particle size of CuO hollow spheres, affecting product purity and output, etc. problem, it is easy to meet the requirements of raw materials, the production cycle is short, and the effect is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The hollow cocoon-like CuO nanomaterial of the present invention is prepared by a one-step microwave heating method, that is, soluble copper salt, deionized water and urea are used as raw materials, and the precursor solution is obtained after stirring and dissolving, and the precursor solution is reacted by microwave heating generate. Its specific process steps are as follows:

[0027] (1) Take 0.1997g copper acetate and be mixed with 10mL deionized water to make solution A;

[0028] (2) Take by weighing 0.1203g urea and be mixed with solution B with 50mL deionized water, the mol ratio of copper salt and urea is 1: 2;

[0029] (3) While stirring, add solution A to solution B to form precursor solution C, the total volume of the solution is 60mL, and continue to stir for 10 minutes;

[0030] (4) Place the precursor solution C in a microwave generator for 30 minutes of microwave irradiation, the reaction temperature is 80°C, the microwave power is 300W, and the magneti...

Embodiment 2

[0036] The hollow cocoon-like CuO nanomaterial of the present invention is prepared by a one-step microwave heating method, that is, soluble copper salt, deionized water and urea are used as raw materials, and the precursor solution is obtained after stirring and dissolving, and the precursor solution is reacted by microwave heating generate. Its specific process steps are as follows:

[0037] (1) Take 0.1999g copper acetate and be mixed with solution A with 10mL deionized water;

[0038] (2) Take 0.0601g of urea and prepare solution B with 50mL of deionized water, the molar ratio of copper salt and urea is 1:1;

[0039] (3) While stirring, add solution A to solution B to form precursor solution C, the total volume of the solution is 60mL, and continue to stir for 10 minutes;

[0040] (4) Place the precursor solution C in a microwave generator for 30 minutes of microwave irradiation, the reaction temperature is 80°C, the microwave power is 300W, and the magnetic stirring rate ...

Embodiment 3

[0045] The hollow cocoon-like CuO nanomaterial of the present invention is prepared by a one-step microwave heating method, that is, soluble copper salt, deionized water and urea are used as raw materials, and the precursor solution is obtained after stirring and dissolving, and the precursor solution is reacted by microwave heating generate.

[0046] Its specific process steps are as follows:

[0047] (1) Take 0.1998g copper acetate and be mixed with 10mL deionized water to make solution A;

[0048] (2) Take by weighing 0.1802g urea and be mixed with solution B with 50mL deionized water, the mol ratio of copper salt and urea is 1: 3;

[0049] (3) While stirring, add solution A to solution B to form precursor solution C, the total volume of the solution is 60mL, and continue to stir for 10 minutes;

[0050] (4) Place the precursor solution C in a microwave generator for 30 minutes of microwave irradiation, the reaction temperature is 80°C, the microwave power is 300W, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com