Cement-based grouting material containing modified melamine water reducer and preparation method thereof

A technology of melamine and grouting materials, which is applied in the field of cement-based grouting materials containing modified melamine water reducers and its preparation, which can solve the problem that the high cost of water reduction can not meet the needs, and it is impossible to determine whether it can really achieve the effect it claims. , did not disclose the preparation method of self-made modified sulfonating agent and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

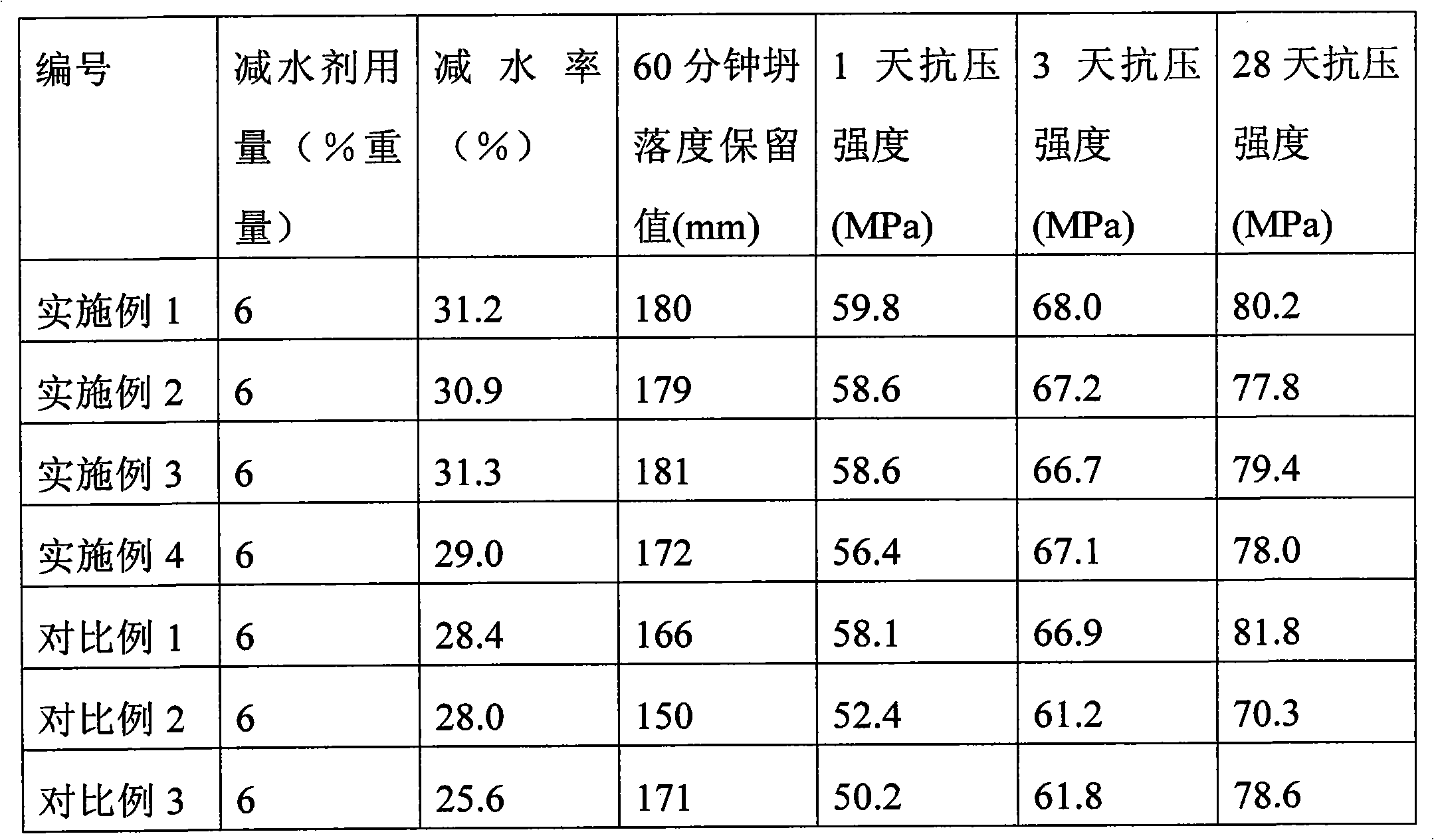

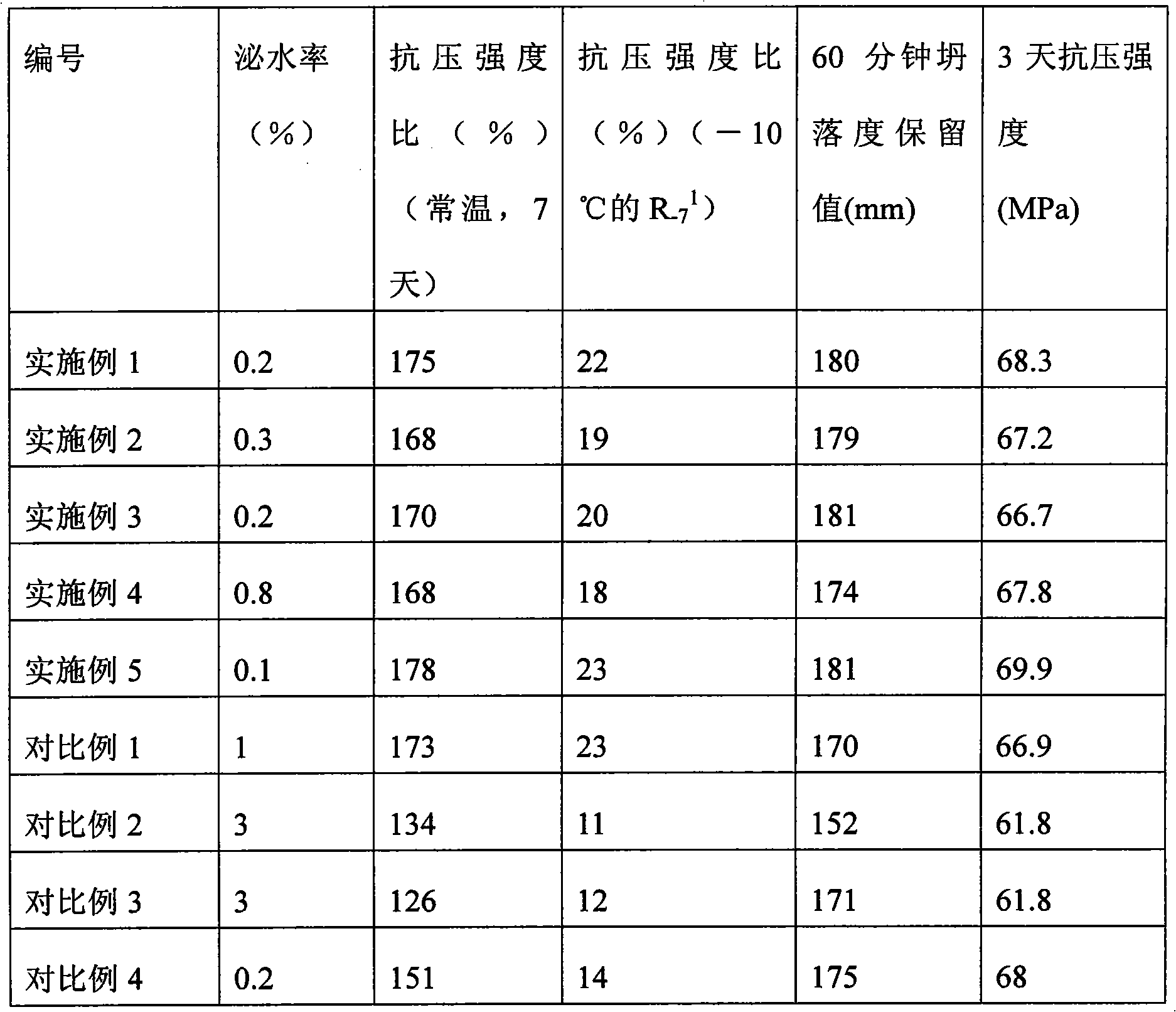

Examples

preparation Embodiment 1

[0037] At room temperature, add concentration to 600Kg water and be 14Kg of sodium hydroxide aqueous solution of 10% by weight, mix uniformly, then add 280Kg phenol, 860Kg sulfanilate, 4300Kg concentration and be the formaldehyde aqueous solution of 36% by weight, after continuing to mix uniformly, Add 220Kg of urea and 1500Kg of melamine, mix, raise the temperature to 80-100°C, and keep warm for 10-50 minutes after the material changes from cloudy to clear to obtain mixture I;

[0038] 2), add 2000Kg water, 1800Kg sodium metabisulfite and 90Kg aqueous sodium hydroxide solution with a concentration of 20% by weight to the mixture I, mix well, raise the temperature to 90-105° C., and keep the temperature for 1-2 hours to obtain the mixture II;

[0039] 3) Add 20Kg of 98% by weight concentrated sulfuric acid to mixture II, then add 30Kg of water, mix well, and keep the temperature at 25°C for 3 hours to obtain mixture III;

[0040] 4) Add 80Kg aqueous sodium hydroxide solution w...

preparation Embodiment 2

[0042] Other conditions are the same as in Example 1, except that 100Kg phenol and 400Kg urea replace 280Kg phenol and 220Kg urea in Example 1.

preparation Embodiment 3

[0044] Other conditions are the same as in Example 1, except that 280Kg of phenol and 220Kg of urea in Example 1 are replaced with 400Kg of phenol and 100Kg of urea.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com