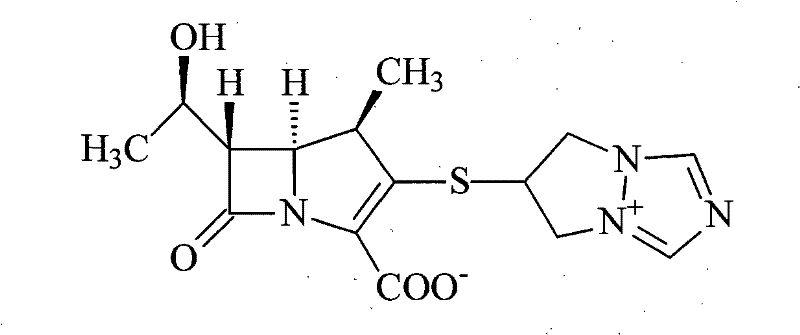

A kind of biapenem compound and its preparation method

A technology for biapenem and compounds, which is applied in the field of biapenem compounds and their purification, and can solve the problems of low purity of biapenem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

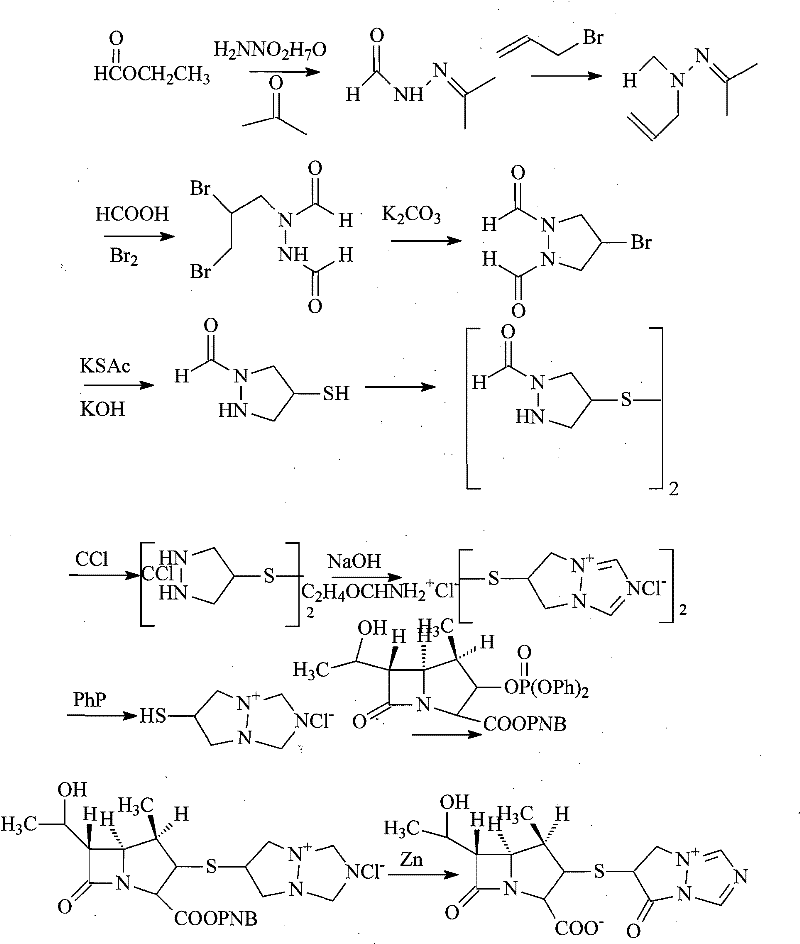

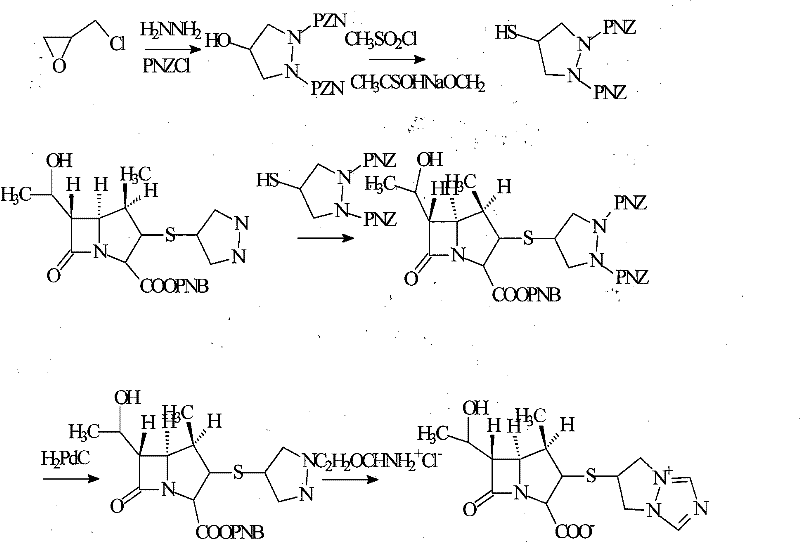

Method used

Image

Examples

Embodiment 1

[0045]Take 10 g of crude biapenem prepared according to the synthetic route 1 of the background art, and the content of biapenem was determined to be 92% by high performance liquid chromatography. Dissolve the crude biapenem in 80ml of water and stir thoroughly to dissolve the biapenem. Then add 0.4 g of activated carbon, keep warm at 40°C, stir for 15 min, filter and decarbonize, and collect the filtrate.

[0046] Add 50ml of a mixed solution of methanol and phosphate buffer (pH 4.0) with a volume ratio of 0.05:1 to the above filtrate, and add it to the top of the silica gel column. The filler is a fine hole with a particle size of 100-175 μm and a pore size of 30-50A Silica gel, column length 20cm, diameter 3cm, column pressure 1.0Pa. Then pump the mixed solution of methanol and phosphate buffer (pH4.0) with a volume ratio of 0.05:1 to carry out column chromatography. Collect in sections to obtain the eluate containing biapenem.

[0047] The obtained biapenem aqueous solu...

Embodiment 2

[0050] Take 10 g of crude biapenem prepared according to the synthetic route 2 of the background technology, and the content of biapenem was determined to be 93% by high performance liquid chromatography. Dissolve the crude biapenem in 100ml of water and stir thoroughly to dissolve the biapenem, then add 1.0g of activated carbon, keep warm at 30°C, stir for 30min, filter and decarbonize, and collect the filtrate.

[0051] Add 60ml of a mixed solution of methanol and phosphate buffer (pH4.0) with a volume ratio of 0.12:1 to the above filtrate, and add it to the top of the silica gel column. Pore silica gel, column length 20cm, diameter 3cm, column pressure 2.5Pa. Then pump the mixed solution of 0.12:1 methanol and phosphate buffer (pH4.0) in volume ratio to carry out column chromatography. Collect in sections to obtain the eluate containing biapenem.

[0052] The obtained biapenem aqueous solution was raised to 55-65°C for concentration. Then add ethanol and acetone mixed ...

Embodiment 3

[0055] Take 10 g of biapenem raw material with a long production date (Hebei Zhongrun Pharmaceutical Co., Ltd. of CSPC, batch number: 20080907), and the content of biapenem was determined to be 96% by high performance liquid chromatography. Dissolve the crude product of biapenem in 120ml of water, stir thoroughly to dissolve the biapenem, then add 0.9g of activated carbon, keep warm at 35°C, stir for 20min, filter and decarbonize, and collect the filtrate.

[0056] Add 70ml of a mixed solution of methanol and phosphate buffer (pH4.0) with a volume ratio of 0.1:1 to the above filtrate, and add it to the top of the silica gel column. Pore silica gel, column length 20cm, diameter 3cm, column pressure 1.8Pa. Then pump the mixed solution of 0.1:1 methanol and phosphate buffer (pH4.0) in volume ratio to carry out column chromatography. Collect in sections to obtain the eluate containing biapenem.

[0057] Raise the obtained biapenem aqueous solution to 70-80°C for concentration....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com