Novel optical anti-fog film and preparation method thereof

An anti-fog film and optical technology, applied in the field of material chemistry, can solve the problems of unsatisfactory anti-fog effect of transparent materials, and achieve the effect of strong light transmittance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Reagents and Instruments

[0033] Cationic polyacrylamide (CPAM, solid content: ≥90%, molecular weight 1000-1200, China),

[0034] Acrylic (PAA, 99.9%, China)

[0035] Sodium silicate (SSI, NaO 2 %>24.0, SiO 2 >53.0, China).

[0036] The solvent is double distilled water (self-made).

[0037] The oven adopts the 601-2 type oven from Dalian Fourth Instrument Factory.

[0038] The contact angle test adopts Drop shape Analysis system DSA20 contact angle tester.

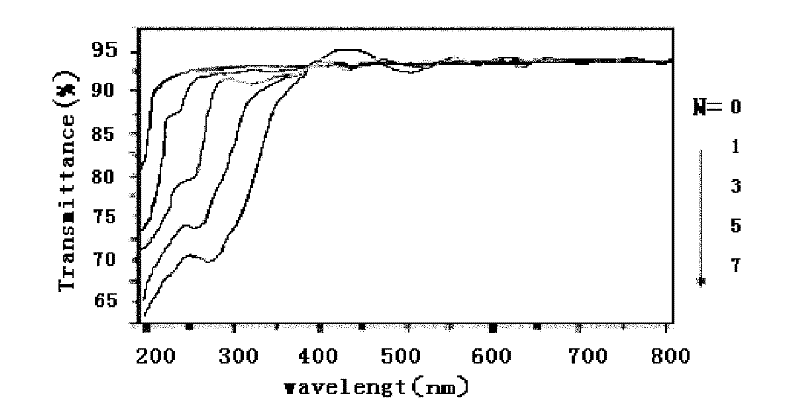

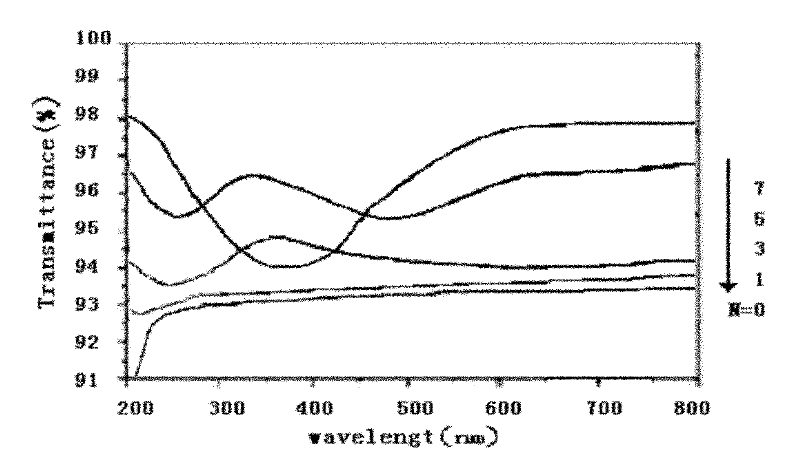

[0039] The light transmittance was measured using a Japanese Hitachi U-2001 ultraviolet spectrophotometer.

[0040] Step 1: Paint Preparation

[0041] Add water-diluted sodium silicate solution with a density of 1.0mg / mL to the cationic polyacrylamide solution dropwise, and stir evenly. The volume ratio of the two solutions is 125mL: 12.5mL. The water temperature is controlled below 60°C, and the pH value of the mixture is adjusted to 4.0 with hydrochloric acid;

[0042] Step 2: Optical Substrate Processi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com