A kind of method for preparing magnesium-lithium alloy coating by precursor polymer

A technology of magnesium-lithium alloy and magnesium alloy, which is applied in the direction of coating, can solve the problems that have not been reported, and achieve the effect of simple equipment, good bonding force and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

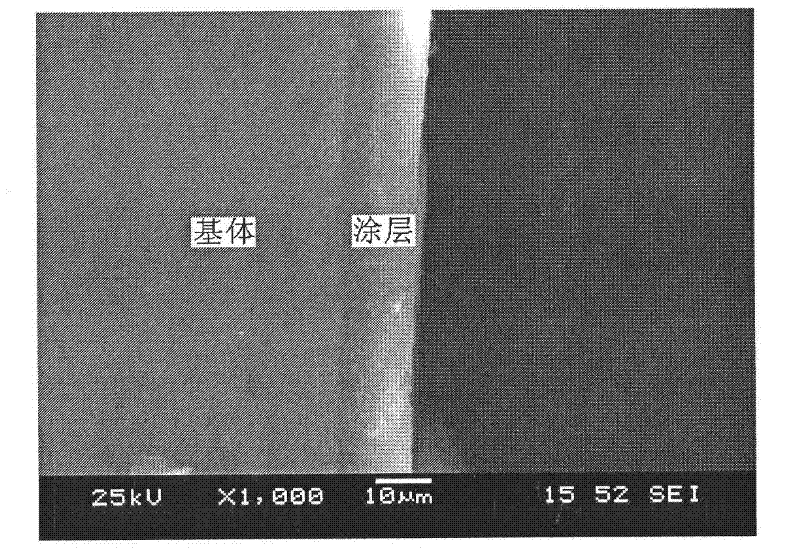

Image

Examples

Embodiment 1

[0025] Embodiment 1: the preparation method of magnesium-lithium alloy coating

[0026] (a) Surface pretreatment of magnesium-lithium alloy: the experiment uses magnesium-lithium alloy as the base material, and its surface pretreatment process mainly includes: polishing-cleaning-drying, that is, using metallographic sandpaper to remove the black film on the surface of magnesium-lithium alloy, After cleaning, blow dry with cold air.

[0027] (b) Preparation of coating: mix a certain concentration of polysilazane with 10-20% B 4 C powder filler and 10-20% SiC powder are mixed in a ball mill for 3 hours to obtain a uniform slurry.

[0028] (c) Spraying: put the slurry into a spray gun, and evenly spray it on the surface of the surface-treated magnesium-lithium alloy.

[0029] (d) Curing process: Put the sample into a nitrogen furnace and heat it up to 200°C at a rate of 5°C / min, keep it warm for 1 hour, and then cool it down at a rate of 5°C / min.

[0030] (e) Reinforcing treat...

Embodiment 2

[0032] Embodiment 2: the preparation method of magnesium-lithium alloy coating

[0033] (a) Surface pretreatment of magnesium-lithium alloy: the experiment uses magnesium-lithium alloy as the base material, and its surface pretreatment process mainly includes: polishing-cleaning-drying, that is, using metallographic sandpaper to remove the black film on the surface of magnesium-lithium alloy, After cleaning, blow dry with cold air.

[0034] (b) Preparation of coating: mix a certain concentration of polycarbosilane with 15% B 4 C powder filler, 10% SiC powder, 8% SiO 2 The powder was mixed in a ball mill for 5 hours to obtain a homogeneous slurry.

[0035] (c) Brushing: evenly brush the slurry onto the surface of the surface-treated magnesium-lithium alloy.

[0036] (d) Curing process: Put the sample into a vacuum furnace and heat it to 180°C at 5°C / min, keep it warm for 2h, and then cool it down at 5°C / min.

[0037] (e) Strengthening treatment: the prepared sample is coate...

Embodiment 3

[0040] Embodiment 3: the preparation method of magnesium-lithium alloy coating

[0041] (a) Surface pretreatment of magnesium-lithium alloy: the experiment uses magnesium-lithium alloy as the base material, and its surface pretreatment process mainly includes: polishing-cleaning-drying.

[0042] (b) Preparation of coating: mix a certain concentration of polysiloxane with a certain proportion of filler 10-20% Al 2 o 3 Powder, 10-20% SiO 2 The powder was mixed in a ball mill for 4 hours to obtain a homogeneous slurry.

[0043] (c) Brushing: evenly brush the slurry onto the surface of the surface-treated magnesium-lithium alloy.

[0044] (d) Curing process: Put the sample into a vacuum furnace and heat it to 200°C at 3°C / min, keep it warm for 1 hour, and then cool it down at 3°C / min.

[0045] (e) Strengthening treatment: the prepared sample is coated with the precursor solution again, and then placed in a vacuum furnace for curing again.

[0046] After the above steps, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com