led

A light-emitting diode and ohmic contact technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of light-emitting diode components such as the decrease of luminous brightness and the increase of opaque area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

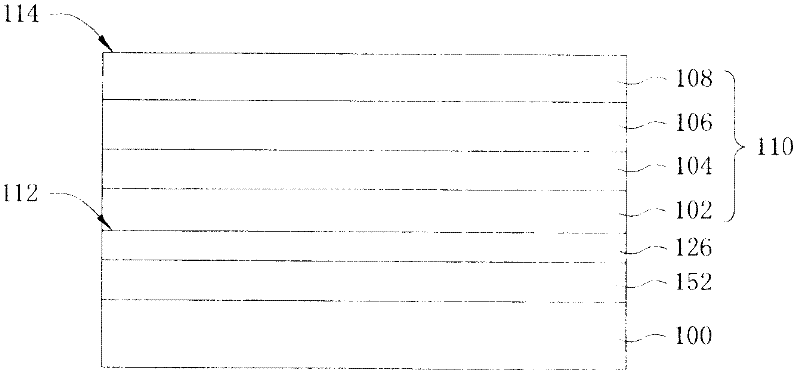

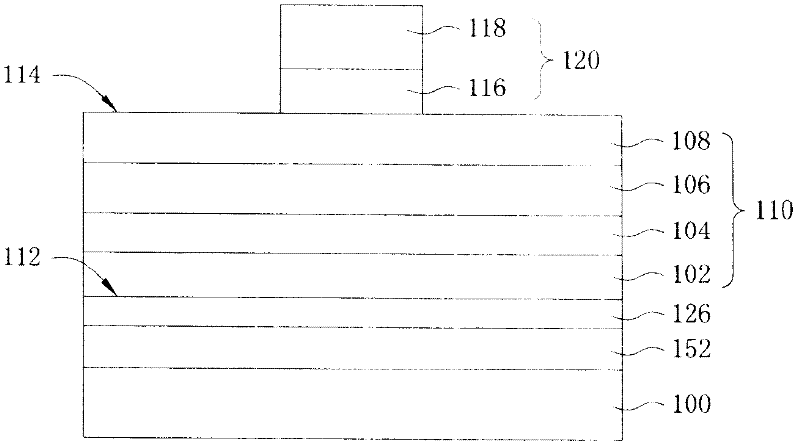

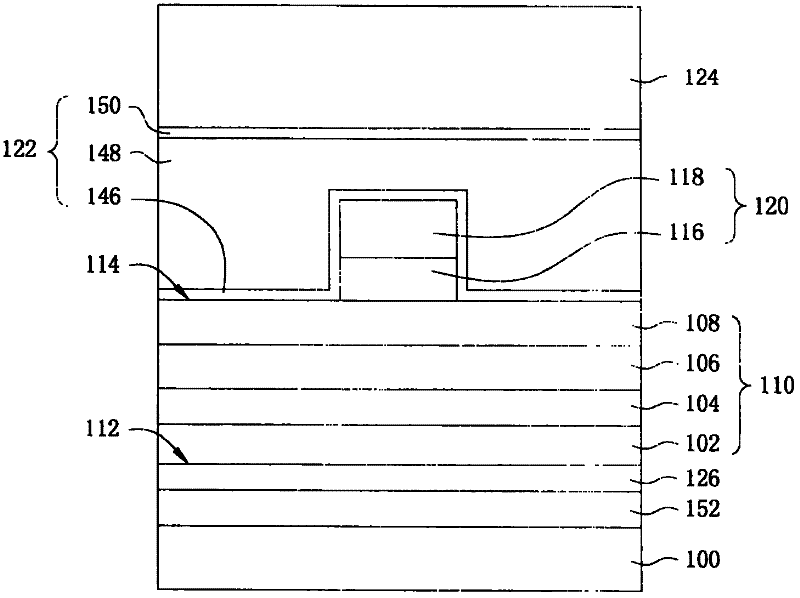

[0020] The invention proposes a high-efficiency light-emitting diode, which can improve the light-emitting brightness of the light-emitting diode assembly, and can improve the operation reliability and stability of the light-emitting diode assembly. In order to make the description of the present invention more detailed and complete, reference may be made to the following descriptions and Figure 1 to Figure 8 icon of the .

[0021] Please refer to Figure 1 to Figure 8 , which is a process cross-sectional view of a high-efficiency light-emitting diode according to a preferred embodiment of the present invention. In an exemplary embodiment of the present invention, when manufacturing the light emitting diode device, the growth substrate 100 is firstly provided, and then the etch stop layer 152 is directly grown on the surface of the growth substrate 100 by, for example, deposition. Next, a first electrical ohmic contact layer 126 is formed on the etch stop layer 152 , wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com