A kind of layered composite material and preparation method thereof

A layered composite material and composite material technology, applied in the field of layered composite materials and its preparation, can solve the problems of affecting the service life of materials, poor palladium high-temperature comprehensive performance, poor high-temperature durable strength of composite materials, etc., and achieve the goal of avoiding high-temperature performance Decrease, improve high-temperature mechanical properties, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

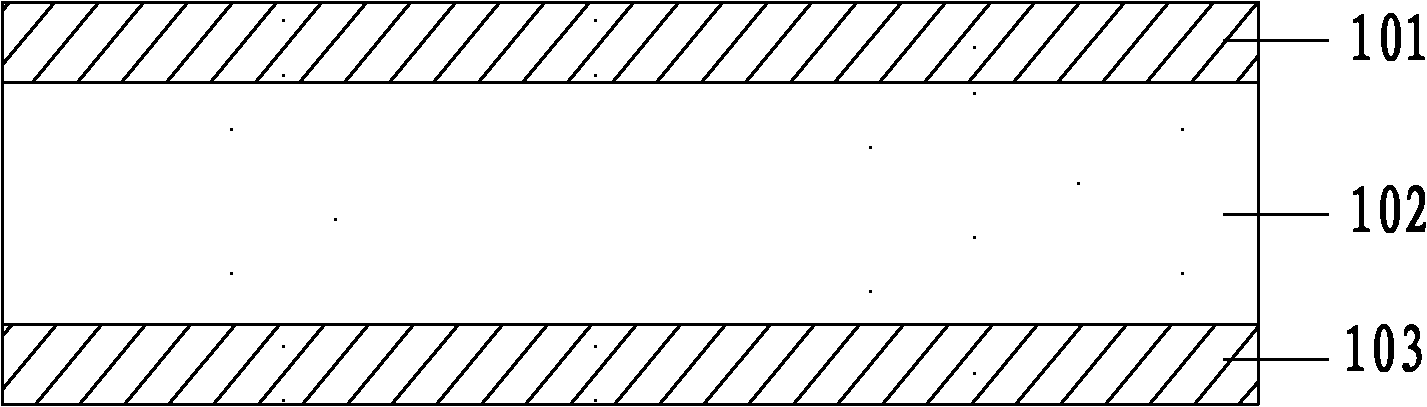

[0028] The present invention also provides a kind of preparation method of layered composite material, comprises the following steps:

[0029] Alloying, casting, and powdering the first noble metal with one or more of Zr, Y, La, and Er to obtain Pt-based multi-element alloy powder, the first noble metal being Pt and / or Rh;

[0030] Alloying, casting, and powdering the second noble metal with one or more of Zr, Y, La, and Er to obtain Pd-based multi-element alloy powder, the second noble metal being Pd and / or the third noble metal, The third noble metal is Rh and / or Ir;

[0031]The Pd-based multi-element alloy powder is placed between two layers of Pt-based multi-element alloy powder for internal oxidation-sintering treatment, hot-press forming and forging treatment to obtain a layered composite material.

[0032] In the present invention, the alloying, casting and powdering treatment of the first noble metal and one or more of Zr, Y, La and Er are carried out, specifically: t...

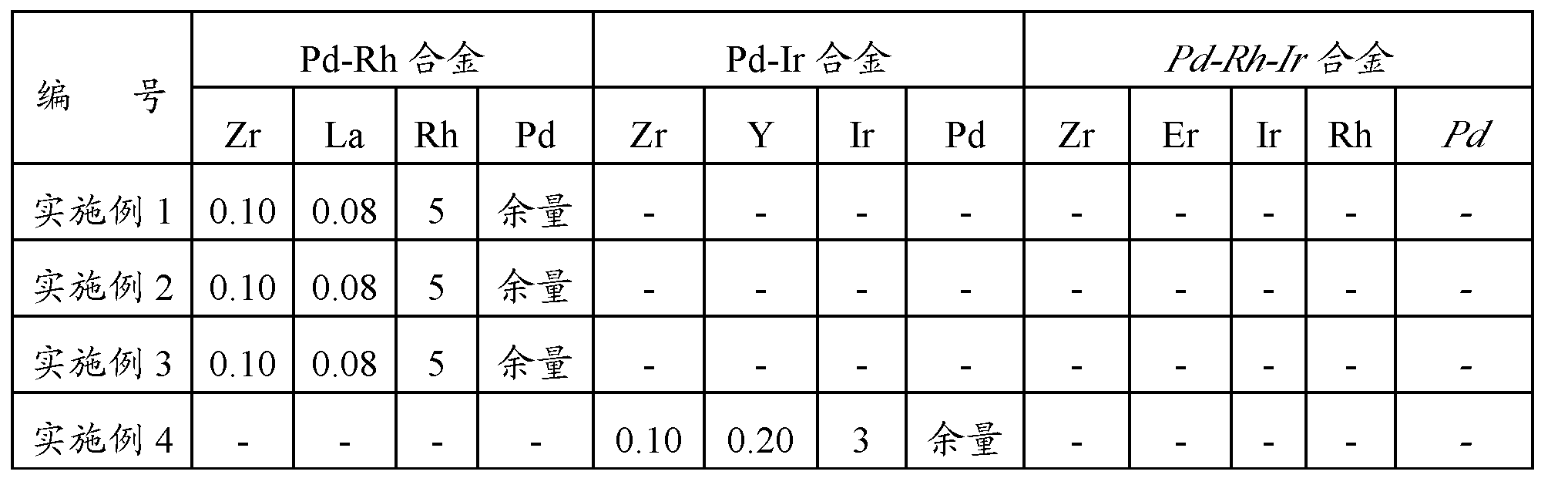

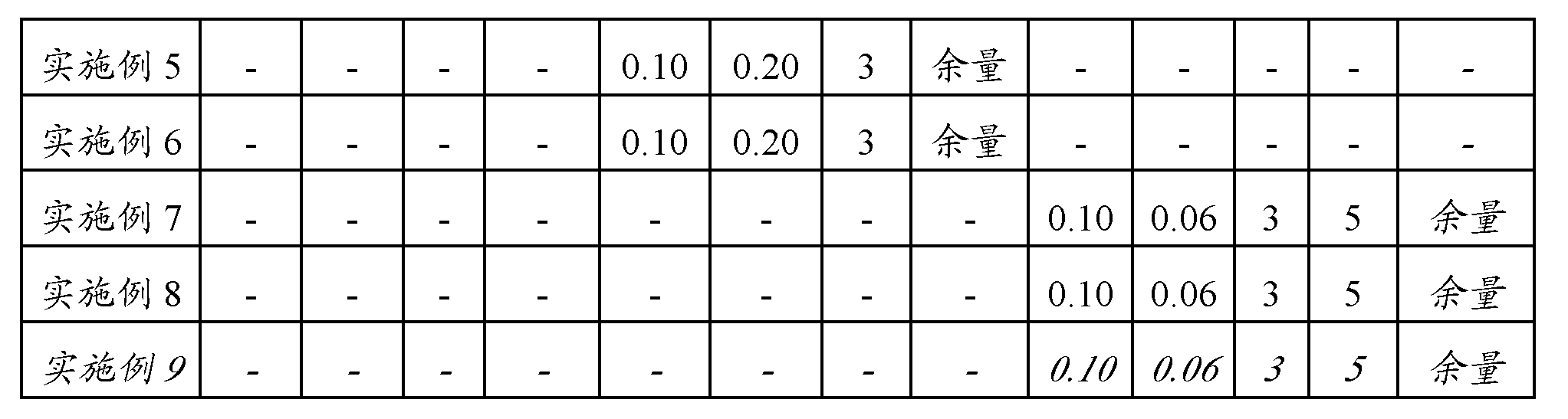

Embodiment 1

[0040] Using 3791.2 grams of Pt, 200 grams of Rh, 4 grams of Zr and 4.8 grams of La as raw materials, melt and cast a Pt-based multi-element alloy containing 0.10wt% Zr and 0.12wt% La in a vacuum induction melting furnace;

[0041] Using 3791.2 grams of Pd, 200 grams of Rh, 4 grams of Zr and 3.2 grams of La as raw materials, melting and casting a Pd-based multi-element alloy containing 0.10wt% Zr and 0.08wt% La in a vacuum induction melting furnace;

[0042] Using a powder metallurgy method to prepare the Pt-based multi-element alloy and the Pd-based multi-element alloy into Pt-based multi-element alloy powder and Pd-based multi-element alloy powder;

[0043] Get 500 grams of the Pt-based multi-element alloy powder and pack it into the bottom layer of the platinum box for compaction, then put 4000 grams of Pd-based multi-element alloy powder into the Pt-based alloy powder and compact it for leveling, then place 500 grams of Pt-based multi-element alloy powder The alloy powder ...

Embodiment 2

[0046] Using 3791.2 grams of Pt, 200 grams of Rh, 4 grams of Zr and 4.8 grams of La as raw materials, melt and cast a Pt-based multi-element alloy containing 0.10wt% Zr and 0.12wt% La in a vacuum induction melting furnace;

[0047] Using 3791.2 grams of Pd, 200 grams of Rh, 4 grams of Zr and 3.2 grams of La as raw materials, melting and casting a Pd-based multi-element alloy containing 0.10wt% Zr and 0.08wt% La in a vacuum induction melting furnace;

[0048] Using a powder metallurgy method to prepare the Pt-based multi-element alloy and the Pd-based multi-element alloy into Pt-based multi-element alloy powder and Pd-based multi-element alloy powder;

[0049] Get 1000 grams of the Pt-based multi-element alloy powder and pack it into the bottom layer of the platinum box for compaction, then put 3000 grams of Pd-based multi-element alloy powder into the Pt-based alloy powder and compact it for leveling, then place 1000 grams of Pt-based multi-element alloy powder The alloy powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com