Method for preparing graphene at normal temperature

A technology of graphene and graphene, which is applied in the field of preparing graphene at room temperature, can solve the problems of semiconductor process incompatibility, environmental pollution, etc., and achieve the effect of overcoming chance, environmental pollution, and high temperature environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Preparation of graphene oxide solution: Take 4mg of graphene oxide, dissolve it in 10ml of deionized water, and undergo ultrasonic dispersion (ultrasonic time 4h, ultrasonic power 100W) to form a uniform aqueous solution of graphene oxide.

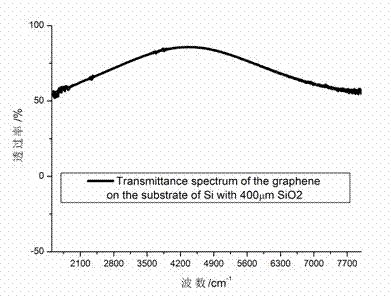

[0045] (2) Preparation of graphene oxide film: Substrate 6 is a double-sided polished N-type silicon wafer (110) covered with 400 nanometers of SiO2 after thermal oxidation treatment, and spin-coated graphene oxide 10 times (low speed 500r / min, time 5s , high speed 1000r / min, time 30s), a uniform graphene oxide film 1 is formed on the surface of the silicon substrate, Figure 5 The optical microscope photos of the surface are given (a, bright-field graphene oxide surface morphology under 100 times objective lens, b, dark-field graphene oxide surface morphology under 100 times objective lens), it can be seen that the size is below 100mm flake graphene oxide.

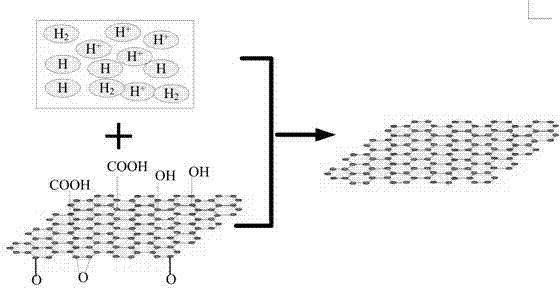

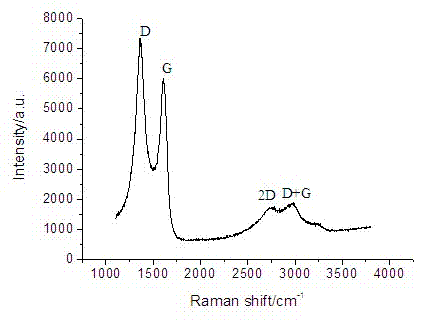

[0046] (3) Reduction to obtain graphene monomer: put the prepared gra...

Embodiment 2

[0048] (1) Preparation of graphene oxide solution: Take 8 mg of graphene oxide, dissolve it in 10 ml of absolute ethanol, and undergo ultrasonic dispersion (ultrasonic time 8 hours, ultrasonic power 50 W) to form a uniform ethanol solution of graphene oxide.

[0049] Preparation of graphene oxide film: substrate 6 is selected through thermal oxidation treatment, and the surface is covered with 400 nanometers of SiO Double-sided polished N-type silicon wafer (110), spin-coated graphene oxide 50 times (low speed 400r / min, time 5s, high speed 1000r / min, time 30s), a uniform graphene oxide film 1 is formed on the surface of the silicon substrate, and the surface of the spin-coated graphene oxide is as follows Figure 7 shown.

[0050] Reduction to obtain graphene monomer: put the prepared graphene oxide into PECVD, flush into H 2 Gas, until the working pressure reaches 67Pa, turn on the RF radio frequency source (power 100W), form a plasma in a vacuum chamber with a vacuum degre...

Embodiment 3

[0052] (1) Preparation of graphene oxide solution: Take 10 mg of graphene oxide, dissolve it in 20 ml of acetone, and undergo ultrasonic dispersion (ultrasonic time 6 h, ultrasonic power 80 W) to form a uniform acetone solution of graphene oxide.

[0053] (2) Preparation of graphene oxide film: take quartz glass as the substrate 6, spin-coat graphene oxide 10 times (low speed 500r / min, time 5s, high speed 1000r / min, time 30s), and form a uniform oxide layer on the surface of the quartz substrate. Graphene film 1, Figure 10 The optical microscope photos of the surface are given (a, bright-field graphene oxide surface morphology under 100 times objective lens, b, dark-field graphene oxide surface morphology under 100 times objective lens), it can be seen that the size is below 100mm flake graphene oxide.

[0054] (3) Reduction to obtain graphene monomer: Put the prepared graphene oxide into the plasma etching (ICP) equipment, pour NH3 gas into it, until the working pressure re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com