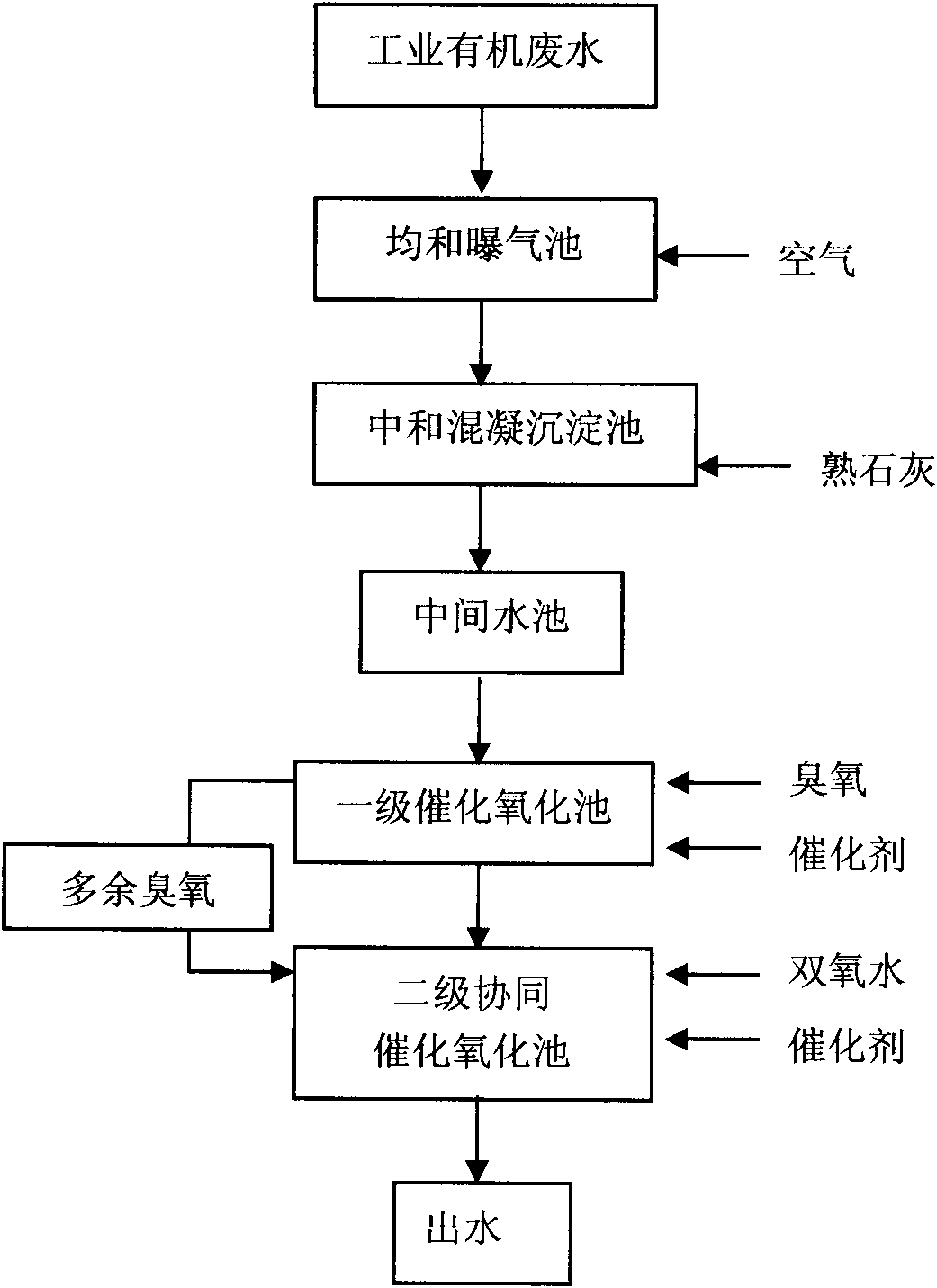

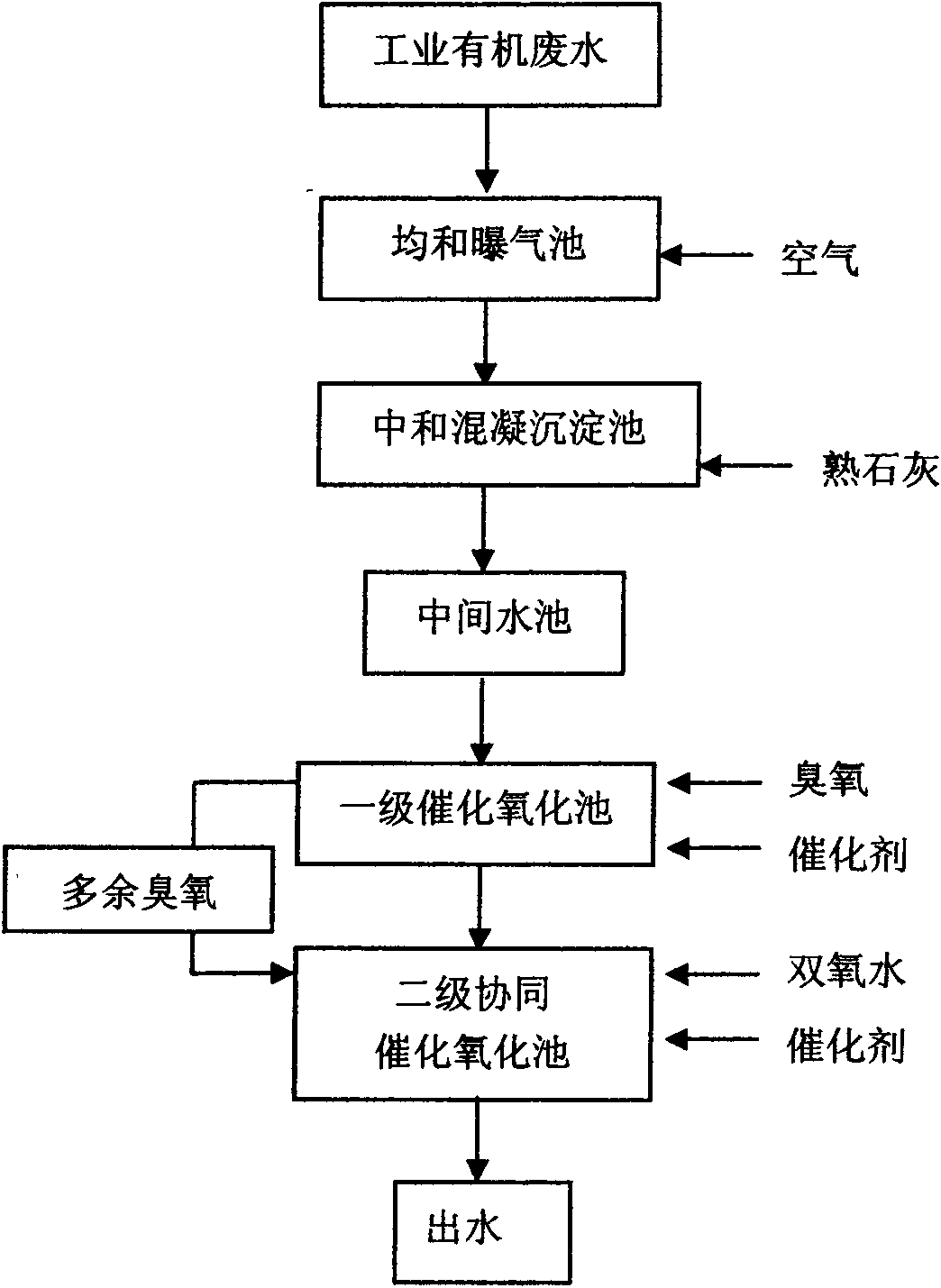

A series catalytic oxidation process for industrial organic wastewater treatment

A technology for catalytic oxidation and organic wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of increasing the difficulty of treatment, refractory biodegradation, and difficult treatment , to achieve the effect of improving processing efficiency, improving utilization efficiency and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment one: by above-mentioned technological process:

[0019]The organic wastewater is pharmaceutical wastewater, the index is: the treatment capacity is 1T, and the concentration is COD: 2000mg / L; the pretreatment of the organic wastewater includes the homogenization and aeration process of the wastewater and the neutralization coagulation sedimentation process, and the homogenization and aeration process The uniform and aeration tank is adopted, and the air aeration intensity is controlled by the uniform and aeration tank to 7m 3 / m 2 .h, fully homogeneous; the neutralization coagulation sedimentation process adopts a neutralization coagulation sedimentation tank, and a shut-off valve is used in the neutralization area to add slaked lime or hydrochloric acid or hydrochloric acid to adjust the pH value. % Coagulant aid PAC, the dosage is controlled at 8mg / L; most of the suspended solids and oil in the wastewater are removed through the pretreatment process.

[0...

Embodiment 2

[0022] Embodiment two: by above-mentioned technological process:

[0023] The organic wastewater is pharmaceutical wastewater, the index is: the treatment capacity is 1T, and the concentration is COD: 2000mg / L. The pretreatment of the organic wastewater includes the homogenization and aeration process of the wastewater and the neutralization coagulation sedimentation process, and the homogenization and aeration process Uniform and aeration tanks are used, and the uniform and aeration tank controls the air aeration intensity to 6m 3 / m 2 .h, fully homogeneous; the neutralization coagulation sedimentation process adopts a neutralization coagulation sedimentation tank, and a cut-off valve is used to add slaked lime or hydrochloric acid to adjust the pH value in the neutralization area, and the pH value is controlled at 6-9, followed by adding 0.5% auxiliary Coagulant PAC, the dosage is controlled at 5mg / L; most of the suspended solids and oil in the wastewater are removed throug...

Embodiment 3

[0026] Embodiment three: by above-mentioned technological process:

[0027] The organic wastewater is pharmaceutical wastewater, the index is: the treatment capacity is 1T, and the concentration is COD: 2000mg / L. The pretreatment of the organic wastewater includes the homogenization and aeration process of the wastewater and the neutralization coagulation sedimentation process, and the homogenization and aeration process Uniform and aeration tanks are used, and the uniform and aeration tanks control the air aeration intensity to 1m 3 / m 2 .h, fully homogeneous; the neutralization coagulation sedimentation process adopts a neutralization coagulation sedimentation tank, and a cut-off valve is used to add slaked lime or hydrochloric acid to adjust the pH value in the neutralization area, and the pH value is controlled at 6-9, followed by adding 0.5% auxiliary Coagulant PAC, the dosage is controlled at 1mg / L; most of the suspended solids and oil in the wastewater are removed thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com