Synergic antiflaming thermoplastic resin and preparation method thereof

A thermoplastic resin and synergistic flame-retardant technology, which is applied in the field of flame-retardant thermoplastic resin and its preparation, can solve problems such as limited applications, and achieve the effects of industrialized production, convenient operation, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 4.0 grams of γ-aminopropyltrimethoxysilane silane coupling agent to 750 ml of distilled water at 40°C, stir to dissolve, add 55.0 grams of magnesium hydroxide powder, stir at high speed, the stirring speed is 4000r / min, the stirring time Suction filtration for 1 hour to obtain a filter cake, put the filter cake into a blast drying oven, heat up from room temperature to 105°C ± 5°C, heat preservation and drying time for 2 hours, and naturally cool to room temperature to obtain 54.5 g The modified magnesium hydroxide is denoted as KH550-MH, and the yield is 99%.

Embodiment 2

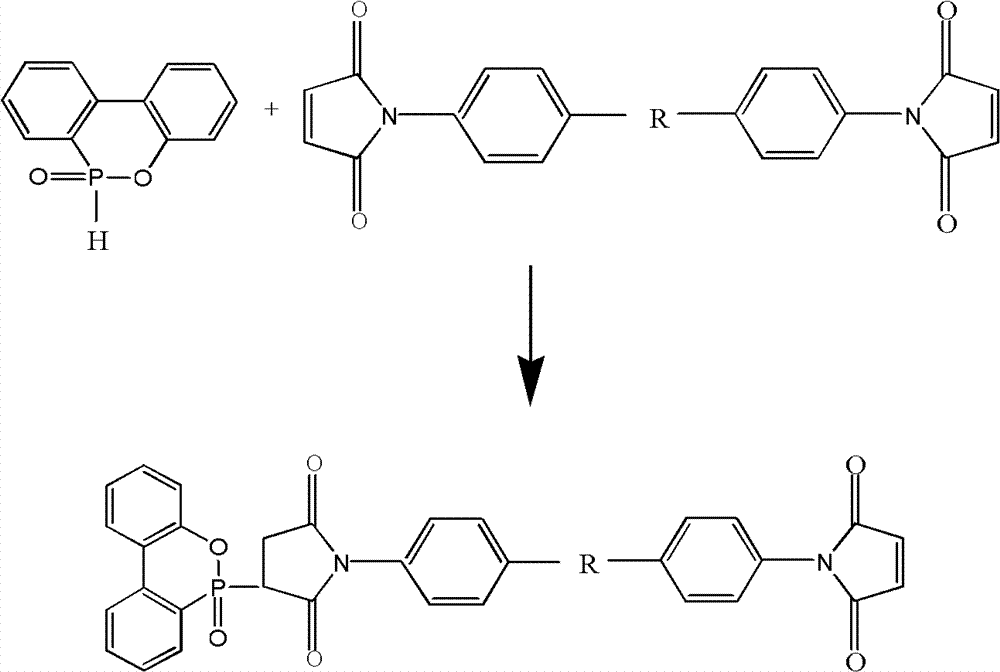

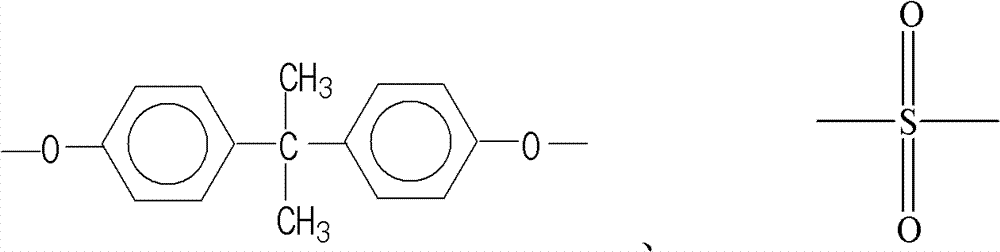

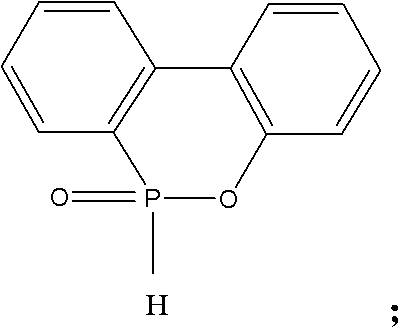

[0039] Add 43.2 grams of DOPO and 71.6 grams of BMI into the reactor, heat up, stir, and melt them. The reaction temperature is 110°C, the reaction time is 20min-40min, and cooled to obtain 113.6 grams of solid products of halogen-free phosphorus-containing flame retardants. , denoted as DB, the yield is 99%.

Embodiment 3

[0041] Weigh 31.5 grams of EVA and 1.4 grams of DB halogen-free phosphorus-containing flame retardant, mix the two evenly, add them to the internal mixer, heat up to 140°C±5°C to melt them, and after banburying evenly, cool down to 60°C±5°C 5°C, add 0.0140g of azobisisobutyronitrile initiator, continue banburying for 2-3 minutes, heat up to 140°C±5°C again, add 37.1g of KH550-MH into the internal mixer, continue banburying for 15min, and produce The raw materials were used to obtain a thermoplastic resin with a synergistic flame-retardant effect of a halogen-free phosphorus-containing flame retardant and a modified magnesium hydroxide. The samples were molded in a flat vulcanizing machine under the conditions of 140°C±5°C and 100kg / cm2. Item properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com