A kind of fluorescent powder based on ultraviolet light or blue light excitation and its preparation method and application

A technology of blue light excitation and fluorescent powder, which is applied in the field of fluorescent materials, can solve the problems of low luminous efficiency, achieve high luminous intensity, wide range of emission wavelengths, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A fluorescent powder excited by ultraviolet light or blue light, the chemical formula of the material is: (M 3-x mn x )(R 2-y Ce y )(Si,Ge) 3 o 12 , wherein when M=Ca and Sr in the chemical formula, R=Sc, x=0.1, y=0.0001, the preparation molecular formula is (Ca 2.5 Sr 0.4 mn 0.1 )(Sc 1.9999 Ce 0.0001 )(Si 2.7 Ge 0.3 )O 12 of fluorescent powder.

[0027] Weigh 2.5molCaCO according to molar ratio 3 , 0.4molSrCO 3 , 0.1molMnCO 3 , 0.99995molSc 2 o 3 , 0.0001molCeO 2 , 2.7mol SiO 2 , 0.3molGeO 2 , mixed and ground evenly, placed in a high-purity corundum crucible, placed in a high-temperature tube furnace for roasting under a hydrogen reducing atmosphere, and roasted at 1400°C for 4 hours to obtain (Ca 2.5 Sr 0.4 mn 0.1 )(Sc 1.9999 Ce 0.0001 )(Si 2.7 Ge 0.3 )O 12 Phosphor.

Embodiment 2

[0029] A fluorescent powder excited by ultraviolet light or blue light, the chemical formula of the material is: (M 3-x mn x )(R 2-y Ce y )(Si,Ge) 3 o 12 , wherein when M=Ca and Sr in the chemical formula, R=Sc, x=0.1, y=0.1, the preparation molecular formula is (Ca 2.5 Sr 0.4 mn 0.1 )(Sc 1.9 Ce 0.1 )(Si 2.7 Ge 0.3 )O 12 of fluorescent powder.

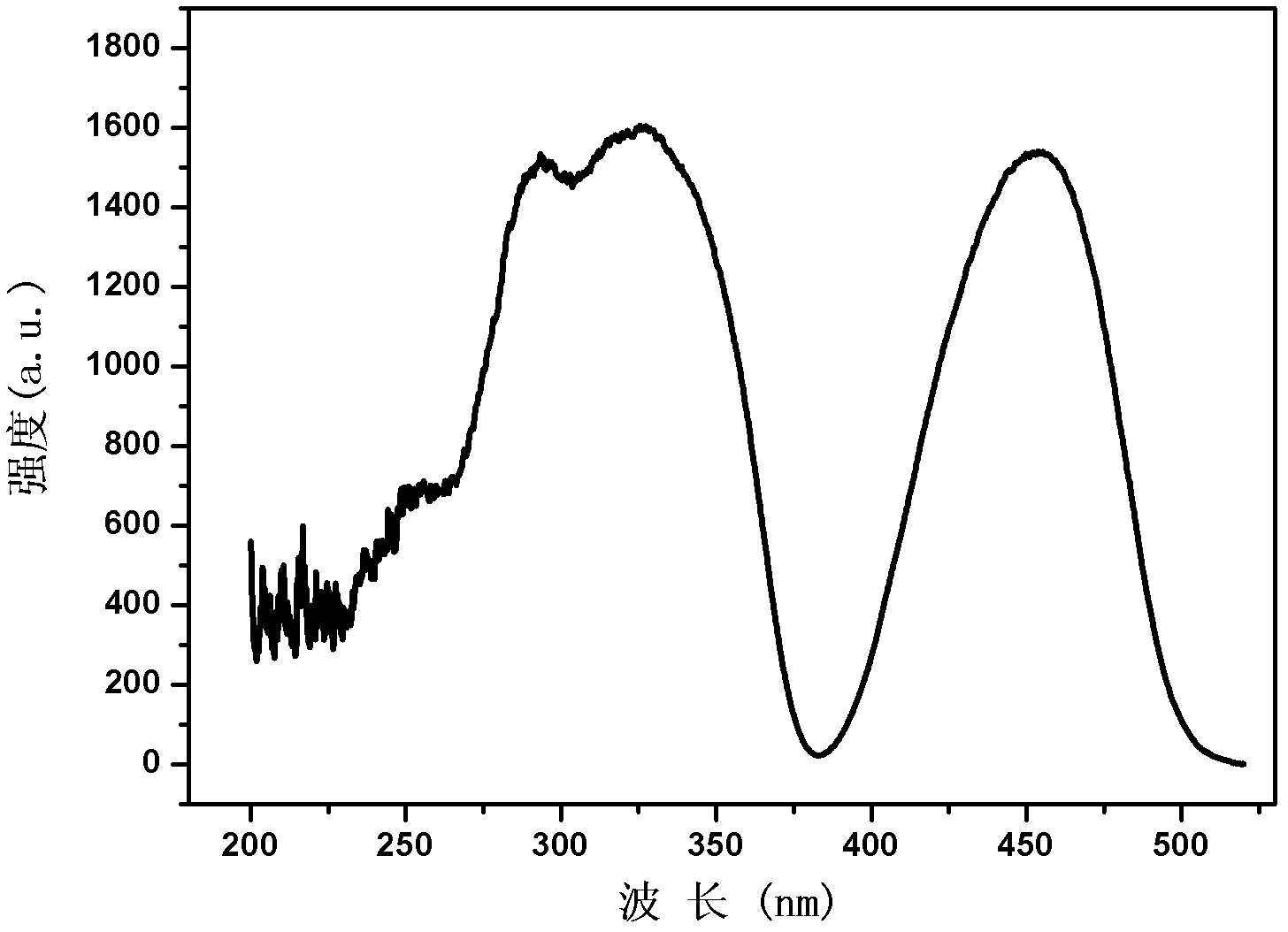

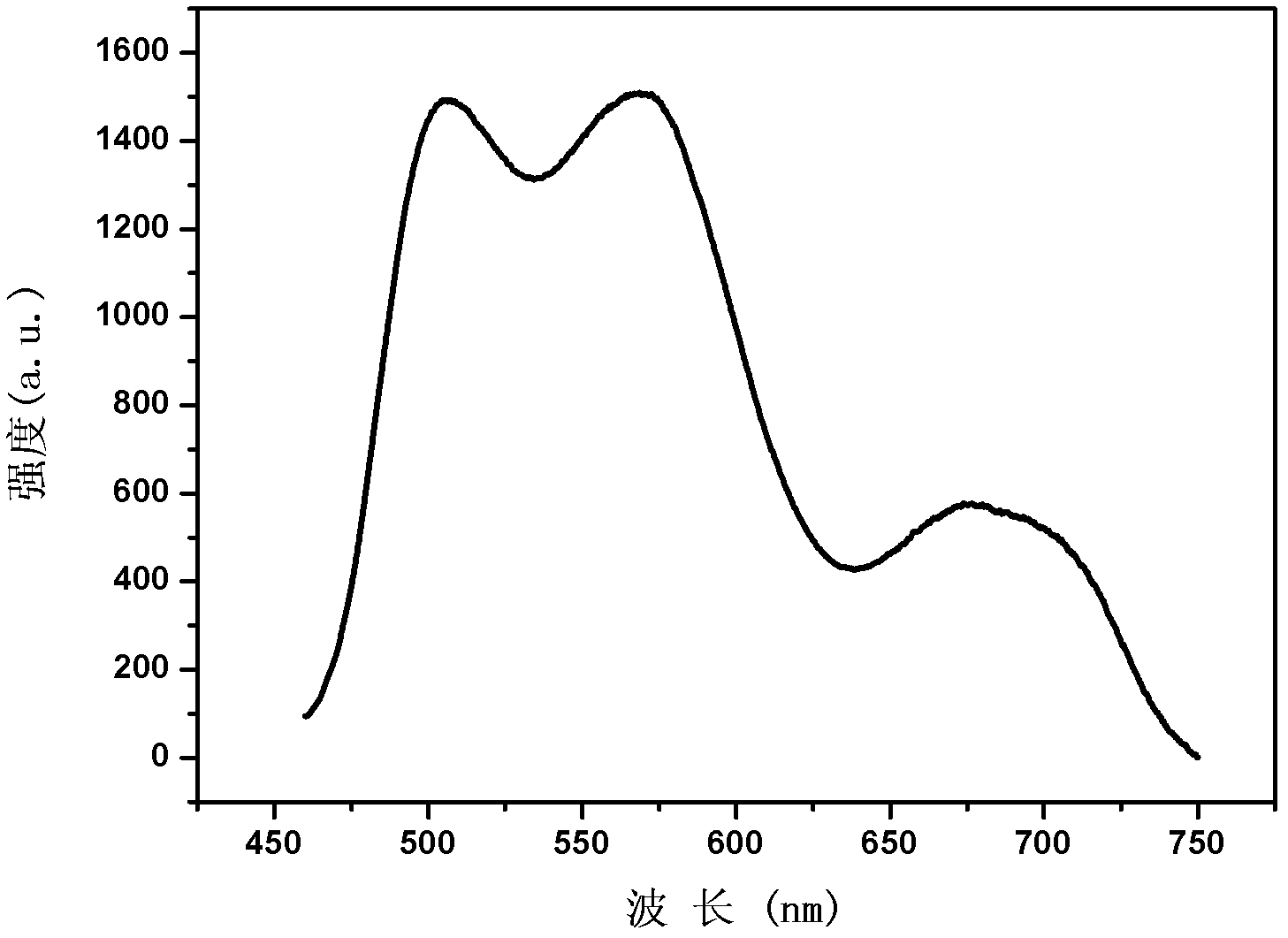

[0030] Weigh 2.5molCaCO according to molar ratio 3 , 0.4molSrCO 3 , 0.1molMnCO 3 , 0.95molSc 2 o 3 , 0.1mol CeO 2 , 2.7mol SiO 2 , 0.3molGeO 2 , after mixing and grinding evenly, put it in a graphite crucible, put it into a high-temperature tube furnace and bake it in a hydrogen reducing atmosphere, and bake it at 1400 ° C for 4 hours to obtain (Ca 2.5 Sr 0.4 mn 0.1 )(Sc 1.9 Ce 0.1 )(Si 2.7 Ge 0.3 )O 12 Phosphor. figure 1 Be the excitation spectrum (λ em =575nm) schematic diagram; figure 2 Be the emission spectrum (λ ex =450nm) schematic diagram.

Embodiment 3

[0032] A fluorescent powder excited by ultraviolet light or blue light, the chemical formula of the material is: (M 3-x mn x )(R 2-y Ce y )(Si,Ge) 3 o 12 , wherein when M=Ca and Sr in the chemical formula, R=Sc, x=0.1, y=0.5, the preparation molecular formula is (Ca 2.5 Sr 0.4 mn 0.1 )(Sc 1.5 Ce 0.5 )(Si 2.7 Ge 0.3 )O 12 of fluorescent powder.

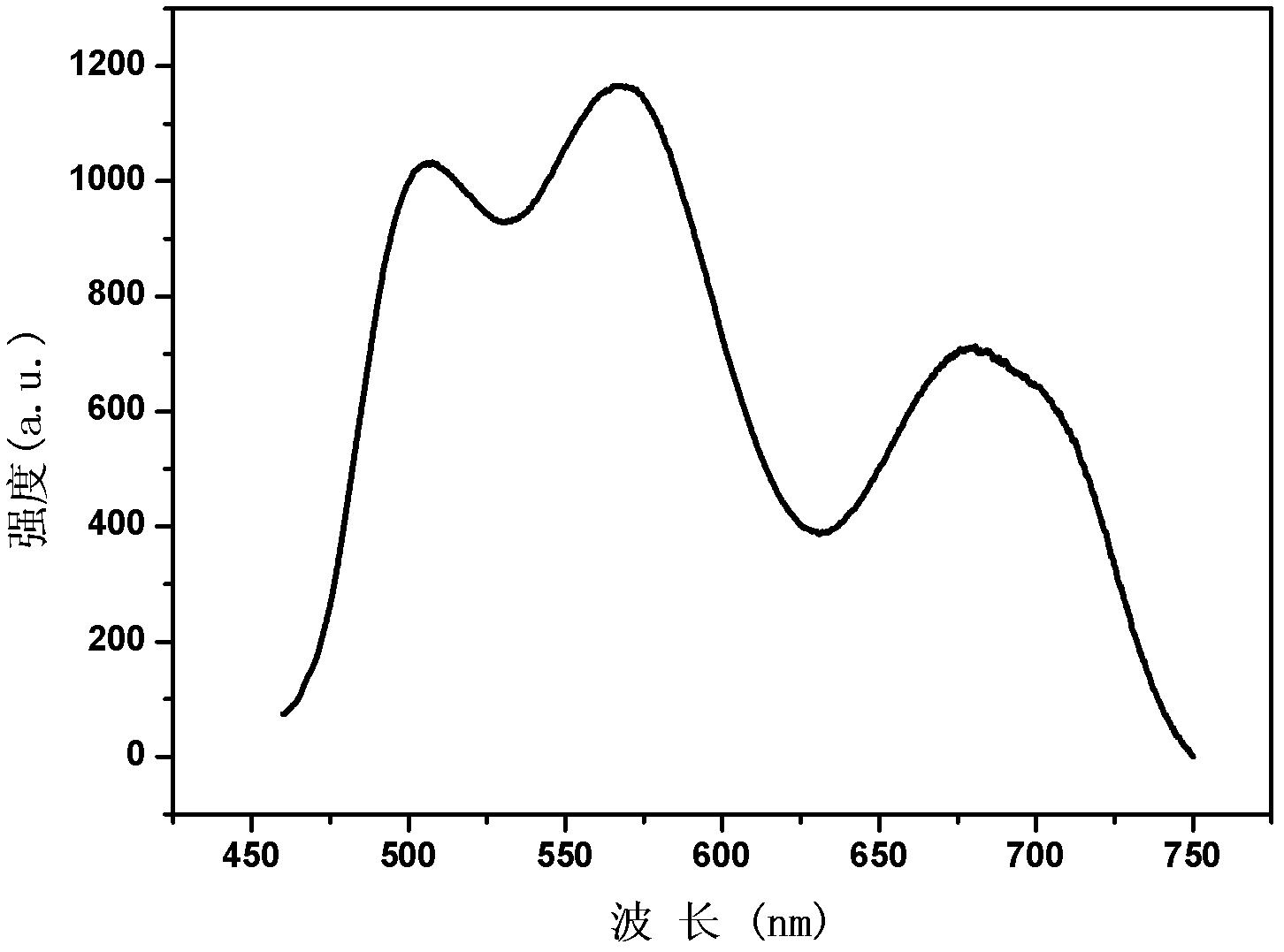

[0033] Weigh 2.5molCaCO according to molar ratio 3 , 0.4molSrCO 3 , 0.1molMnCO 3 , 0.75molSc 2 o 3 , 0.5molCeO 2 , 2.7mol SiO 2 , 0.3molGeO 2 , after mixing and grinding evenly, put it in a platinum crucible, put it into a high-temperature tube furnace for roasting under the condition of hydrogen reducing atmosphere, and roast it at 1400°C for 4 hours to obtain (Ca 2.5 Sr 0.4 mn 0.1 )(Sc 1.5 Ce 0.5 )(Si 2.7 Ge 0.3 )O 12 Phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com