Flat Integral Solar Water Heater

A solar water heater, an integrated technology, applied to solar collectors, solar collectors using working fluids, solar thermal energy, etc., can solve problems such as high operation and maintenance costs, complex and cumbersome systems, and large amounts of copper metal, and achieve The effect of reducing system materials and precious metals, simplifying the manufacturing process, and simplifying the heat exchange process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

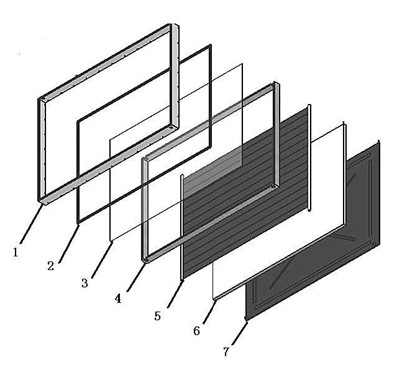

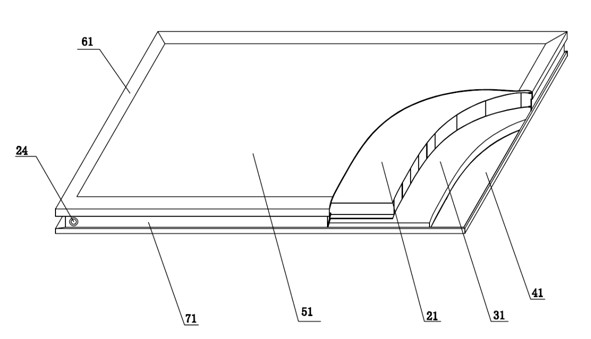

[0026] like image 3 , Figure 4 , Figure 5 As shown, a flat-panel integral solar water heater includes a flat-plate box 21 made of special corrosion-resistant aluminum alloy profiles, and a cover of solar fabric tempered glass is covered at a distance of 15-18mm from the board box 21 The board 51, the surface of the board box 21 facing the cover plate 51 is coated with a solar energy selective heat absorption film layer (not shown in the figure), the solar energy selective heat absorption film layer can use magnetron sputtering, sol spraying , chemical plating (black chrome) and other materials and process methods for coating. A bottom plate 41 is arranged below the board box 21 , and a frame 71 is surrounded by the outer circle of the cover plate 51 , the board box 21 and the bottom plate 41 , and is pressed together by a bead 61 , and the frame 71 is passed through by four frame sections. The four corners are bonded with weather-resistant strong glue, the contact part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com