nanoimprint method

A technology of nanoimprinting and embossing machine, which is applied in nanotechnology, nanotechnology, nanotechnology for information processing, etc., and can solve the problem of reduced mechanical stability of nanoimprinting resist, unfavorable application, and template pretreatment process Complicated problems, to achieve the effect of ensuring integrity and resolution, ensuring resolution and fidelity, and reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

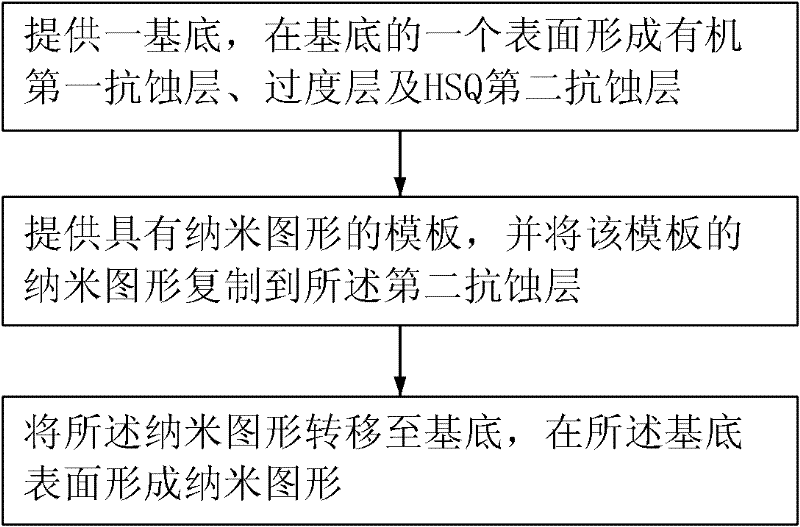

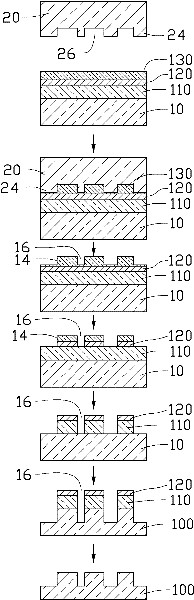

[0028] see figure 1 and figure 2 , using the first embodiment of the nanoimprint method provided by the present invention, which includes the following steps:

[0029] In step S11 , a substrate 10 is provided, and a first resist layer 110 , a transition layer 120 and a second resist layer 130 are sequentially formed on a surface (not shown) of the substrate 10 .

[0030] Firstly, the first resist layer 110 is formed on the surface of the substrate 10 .

[0031] A substrate 10 is provided, and the substrate 10 is cleaned; an organic resist is deposited on a surface of the substrate 10 and then dried to form the first resist layer 110 . The organic resist can be deposited on the substrate 10 by screen printing or spin coating to form the first resist layer 110 . In this embodiment, the organic resist is positive resist ZEP520.

[0032] The material of the base 10 can be a hard material, such as silicon, silicon dioxide, silicon nitride or gallium nitride, and the material o...

no. 2 example

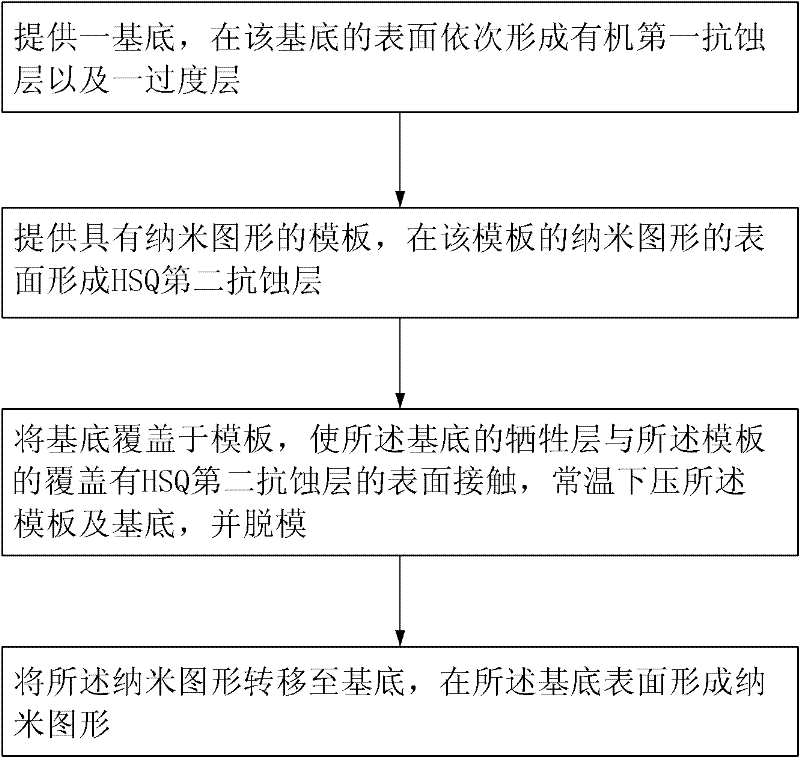

[0053] see image 3 and Figure 4 , the second embodiment of the nanoimprint method using the nanoimprint anti-decoration agent of the present invention, which includes the following steps:

[0054] In step S21 , a substrate 30 is provided, and a first resist layer 310 and a transition layer 320 are sequentially formed on the surface of the substrate 30 .

[0055] In this embodiment, the material of the substrate 30 is completely the same as that of the substrate 10 in the first embodiment, and the manufacturing method, structure, material and positional relationship of the first resist layer 310 and the transition layer 320 are respectively the same as those in the first embodiment. The manufacturing method, structure, material and positional relationship of the first resist layer 110 and the transition layer 120 are completely the same.

[0056] Step S22 , providing a template 60 with nanopatterns on the surface, and forming a second resist layer 330 on the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com