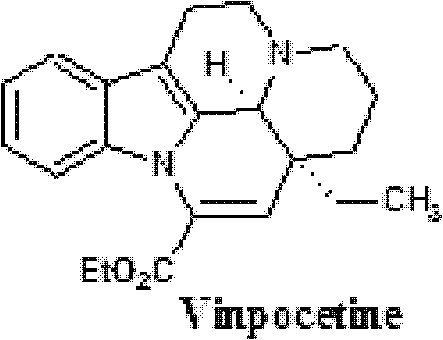

A kind of oral sustained-release solid preparation with vinpocetine as active ingredient

A vinpocetine, slow-release solid technology, applied in the field of medicine, can solve the problems of low patient compliance and frequent drug administration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

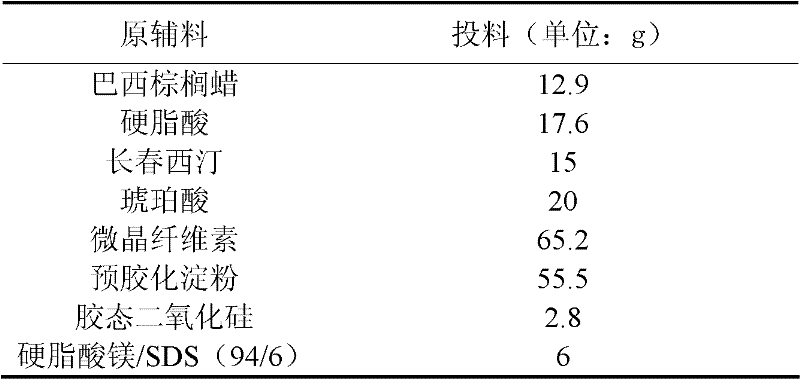

[0034] Embodiment 1 Vinpocetine sustained-release tablet

[0035] Make 1000 Vinpocetine slow-release tablets with the raw materials of following weight ratio

[0036] Extended release partial prescription:

[0037]

[0038] Sustained release part preparation process:

[0039] 1. Pass succinic acid through a 100-mesh sieve, crush vinpocetine, pass through a 100-mesh sieve, and set aside.

[0040] 2. Take carnauba wax, stearic acid, and succinic acid, heat in a water bath at 90°C, stir, and melt, add succinic acid, stir evenly, add vinpocetine, and stir evenly. Stirring was continued, the water bath was removed, and the mass was allowed to cool. A waxy lump was obtained.

[0041] 3. Pulverize the waxy block obtained above, pass through a 60-mesh sieve, add microcrystalline cellulose, pregelatinized starch, and colloidal silicon dioxide, and mix well.

[0042] 4. Add magnesium stearate / SDS (94 / 6) as a lubricant and mix well.

[0043] 5. Prepare 6% Opadry common coating a...

Embodiment 2

[0045] Embodiment 2 Vinpocetine slow-release dry suspension

[0046] Extended release partial prescription:

[0047]

[0048]

[0049] Sustained release part preparation process:

[0050] 1. Pass succinic acid through a 100-mesh sieve, crush vinpocetine, pass through a 100-mesh sieve, and set aside.

[0051] 2. Take carnauba wax, stearic acid, and succinic acid, heat in a water bath at 90°C, stir, and melt, add succinic acid, stir evenly, add vinpocetine, and stir evenly. Stirring was continued, the water bath was removed, and the mass was allowed to cool. A waxy lump was obtained.

[0052] 3. Crush the waxy block obtained above, pass through a 60-mesh sieve, add microcrystalline cellulose, pregelatinized starch, and colloidal silicon dioxide, mix well, add water-based soft materials, extrude and spheronize to make pellets, During the spheronization process, talcum powder is continuously added, and the particle size is 0.5-1.0mm. Sustained-release pellets 1 were obtai...

Embodiment 3

[0069] Embodiment 3: common tablet

[0070] Make 1000 Vinpocetine tablets with the raw materials of following weight ratio

[0071] prescription:

[0072]

[0073] Preparation Process:

[0074] 1. Crush Vinpocetine, pass through a 100-mesh sieve, and set aside.

[0075] 2. Take microcrystalline cellulose and lactose, grind them through a 60-mesh sieve, and set aside.

[0076] 3. Take microcrystalline cellulose, lactose, vinpocetine, and HPMC K4M and mix them uniformly using the method of equal volume increments. Use purified water as a binder to make soft materials, granulate with 24 sieves, dry at 60°C, and control the moisture at 3-5%, granulated with 40 mesh sieve.

[0077] 4. Add magnesium stearate as a lubricant and mix well. Tablet.

[0078] 5. Carry out film coating to above-mentioned plain tablet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com