cds/in2s3/cos composite photocatalyst and preparation method thereof

A composite light and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low catalyst activity and low hydrogen production rate, and achieve good catalyst activity and low reaction temperature , the effect of low reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

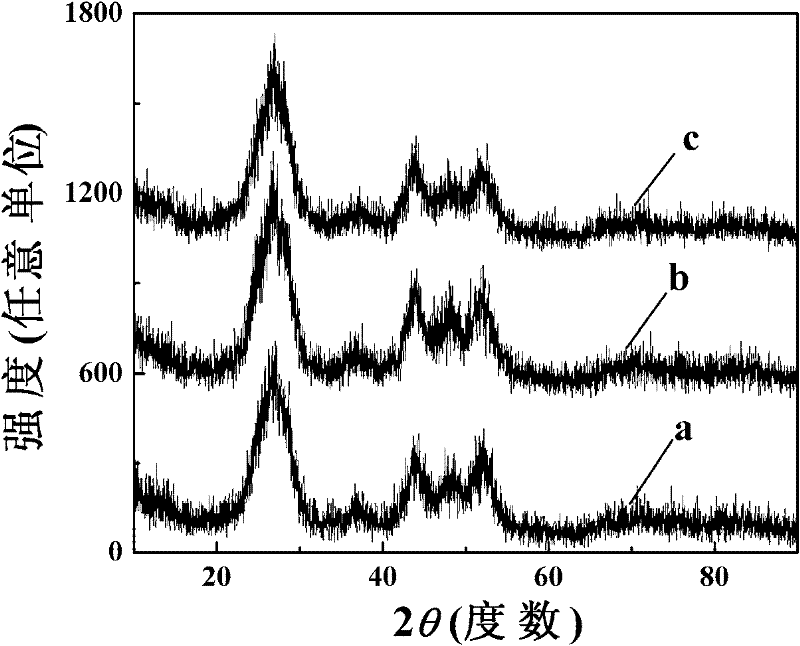

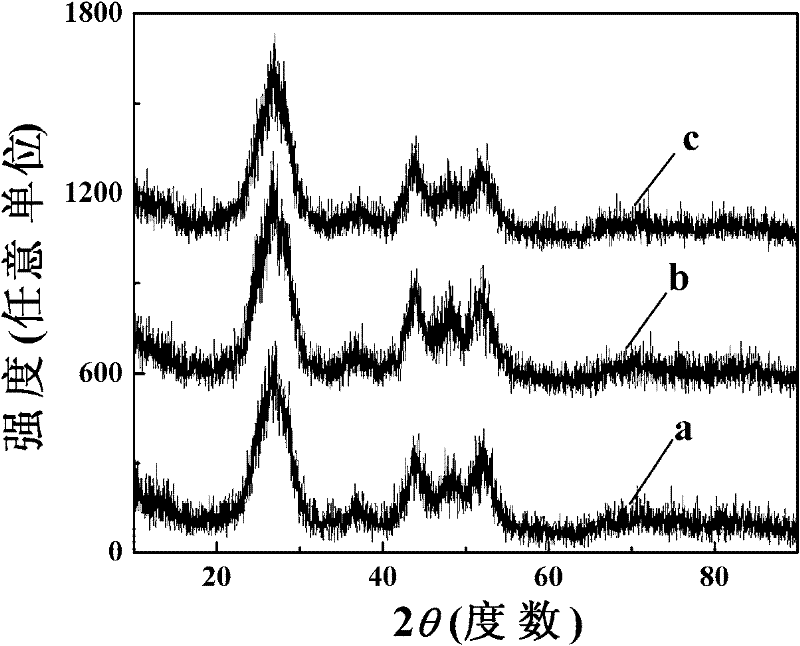

[0011] Specific implementation mode 1: this implementation mode CdS / In 2 S 3 / CoS composite photocatalyst is composed of Cd(Ac) 2 2H 2 O, Co(Ac) 2 4H 2 O, InCl 3 4H 2 Made from O and thioacetamide; where Cd(Ac) 2 2H 2 O and InCl 3 4H 2 The molar ratio of O is 3:0.1~1, Cd(Ac) 2 2H 2 O and Co(Ac) 2 4H 2 The molar ratio of O is 3:0.01~1, Cd(Ac) 2 2H 2 The molar ratio of O to thioacetamide is 1:3-12.

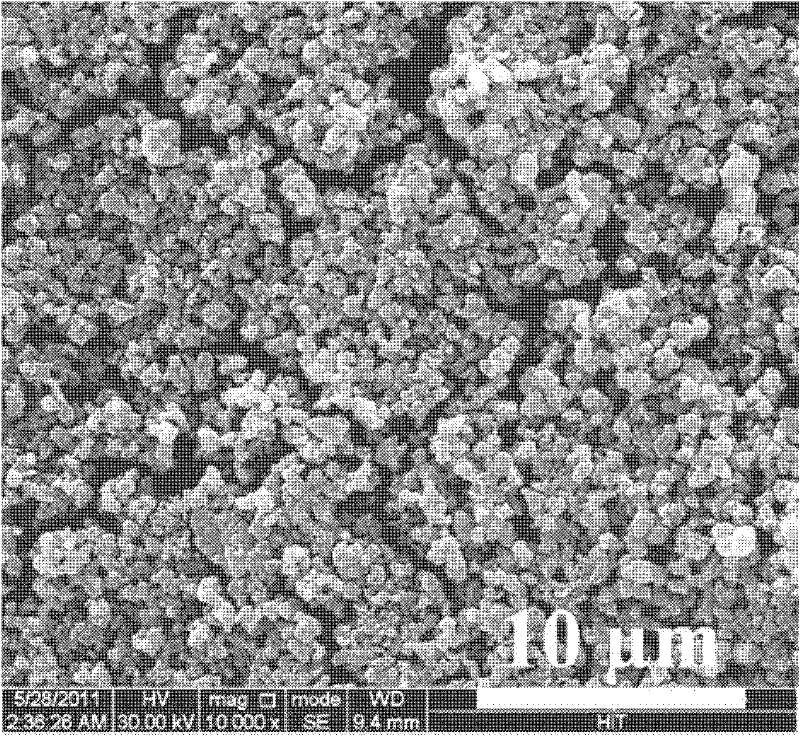

[0012] CdS / In of the present embodiment 2 S 3 The particle size of the / CoS composite photocatalyst is about 500nm, and it is self-assembled by many small particles with a particle size of 10-20nm, and its hydrogen production rate can reach 2-4mmol / h.

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is: Cd(Ac) 2 2H 2 O and InCl 3 4H 2 The molar ratio of O is 3:0.1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one is: Cd(Ac) 2 2H 2 O and InCl 3 4H 2 The molar ratio of O is 3:1. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com