Brake wheel full metal casting mold

A casting mold, metal mold technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of high operator requirements, long product production cycle, dust pollution of the environment, etc., to reduce technical requirements, reduce Modeling process, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

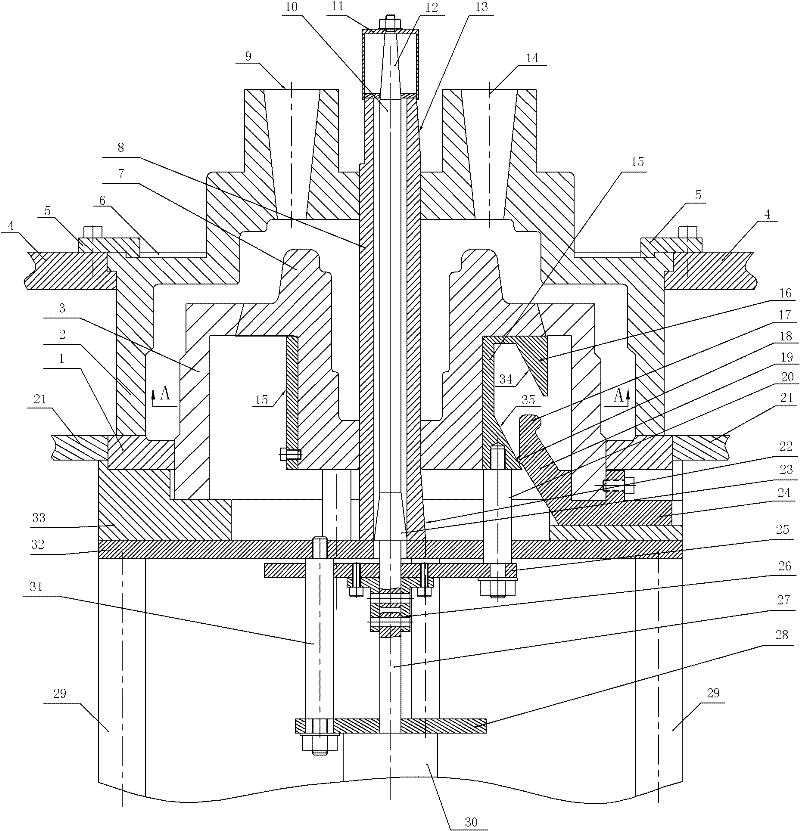

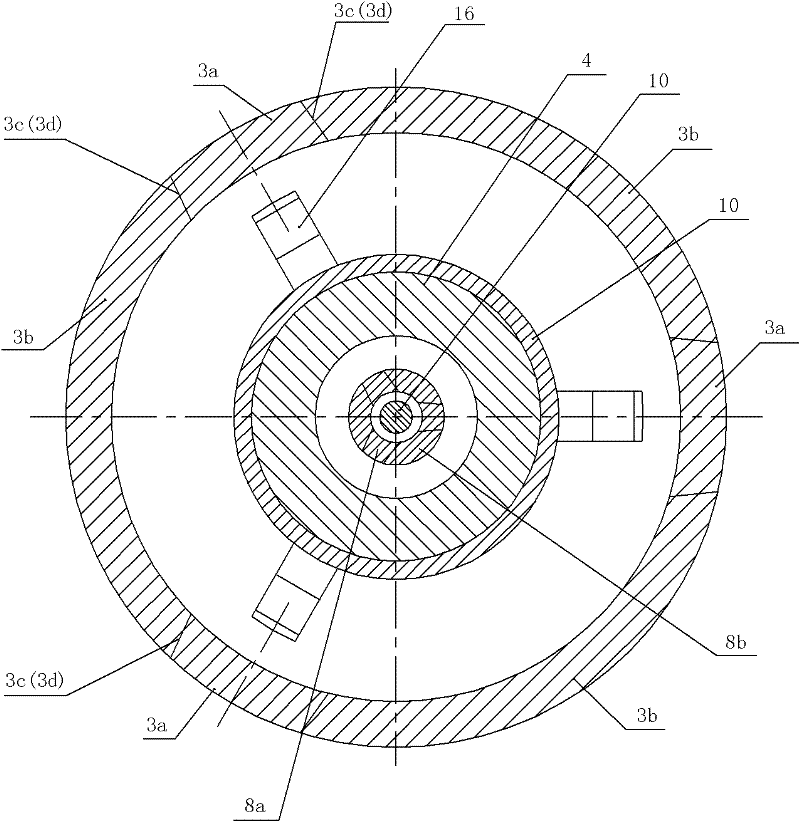

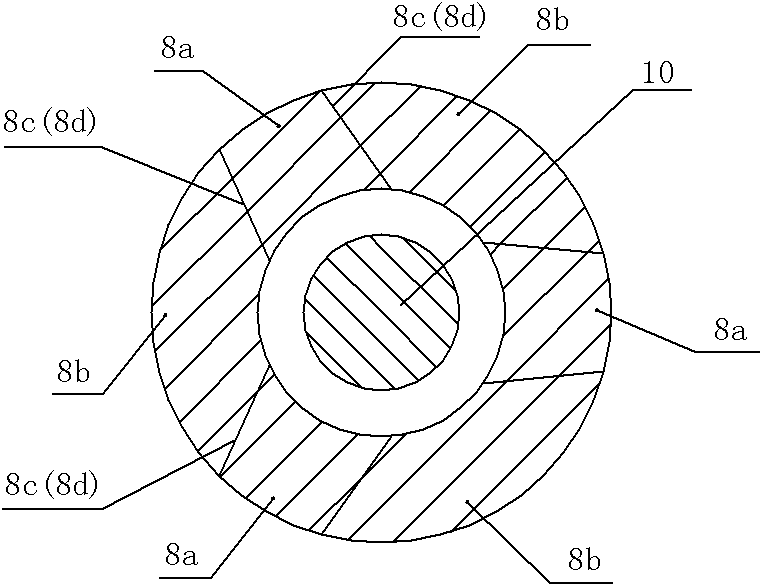

[0027] Such as Figure 1 to Figure 3 As shown, the all-metal casting mold of the brake wheel of the present invention (hereinafter referred to as "casting mold"), the casting mold includes an outer metal mold for forming the outer surface of the outer wall of the brake wheel, and an inner metal mold for forming the inner cavity wall of the brake wheel And the inner hole metal mold 8 of molding brake wheel endoporus, in the present embodiment, outer metal mold, inner metal mold and inner hole metal mold 8 are the metal molds that are made by alloy cast iron or cast steel, certainly also can use other Made of high temperature resistant metal material.

[0028] The outer metal mold includes the outer metal mold I2 for forming the outer wall side and the upper end surface of the brake wheel and the outer metal mold II1 for forming the lower end surface of the outer wall. The top of the outer metal mold I2 is respectively provided with a sprue 14 and a riser 9, and the outer metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com