A kind of preparation method of α-tocopheryl acetate

A technology of tocopherol acetate and concentrated sulfuric acid, applied in the direction of organic chemistry, chemical recovery, etc., can solve the problems of difficult catalyst recovery, large amount of catalyst, toxic and side effects of products, etc., and achieves easy recovery and application, easy recovery, and catalyst usage. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

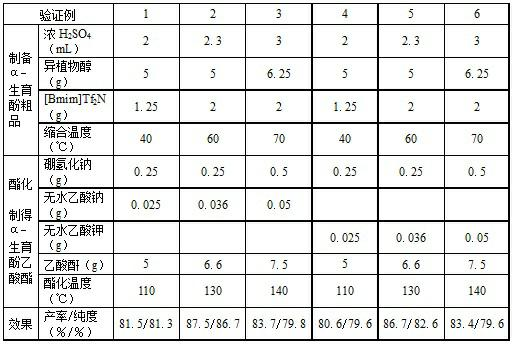

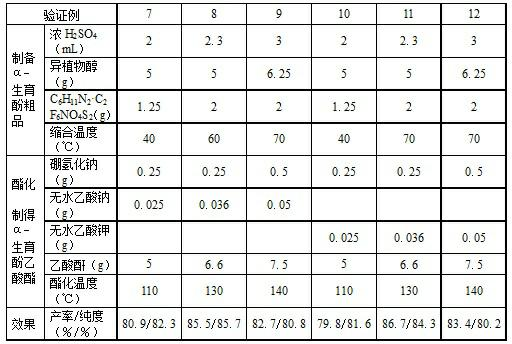

Examples

Embodiment Construction

[0014] A kind of preparation method of α-tocopherol acetate, this method is to use catalyst to promote the method for condensation reaction of raw material trimethylhydroquinone and isophytol, in the present invention, described catalyst is concentrated sulfuric acid (H 2 SO 4 ) and amine ionic liquid, wherein the amine ionic liquid is 1-butyl-3-methylimidazolium trifluoromethanesulfonimide salt ([Bmim]Tf 2 N) or 1-ethyl-3-methylimidazoline bis(trifluoromethylsulfonyl)imide (C 6 h 11 N 2 ·C 2 f 6 NO 4 S 2 ); the method steps are as follows:

[0015] (1) Slowly add concentrated sulfuric acid to acetic acid C at 0°C under stirring 2~4 In the alkyl ester, to prepare the reaction solvent; Among them, acetic acid C 2~4 The purity of the alkyl esters is 99.5%; the volume ratio of the amount of added concentrated sulfuric acid to the total amount of the reaction solvent is 0.2~0.3:5;

[0016] It is clear to those skilled in the art that the concentration of concentrated sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com