Special adhesive resin for aluminum-plastic pipe and preparation method thereof

A technology for bonding resins and aluminum-plastic pipes. It is used in adhesives, adhesive types, grafted polymer adhesives, etc. It can solve the problems of high and low temperature resistance and poor durability, and achieve good bonding effect, mechanical The effect of excellent performance and huge market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

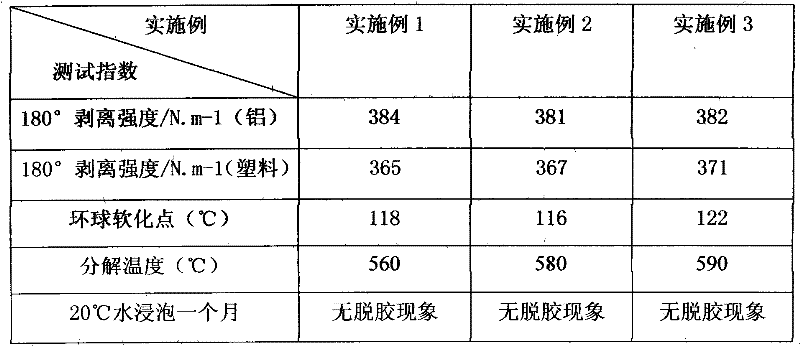

Examples

Embodiment 1

[0023] Adhesive resin for aluminum-plastic pipes (parts by mass):

[0024] High Density Polyethylene (HDPE)

[0025] Heat and stir through the reaction kettle, according to the above formula ratio, first heat and melt the matrix resin (HDPE, LLDPE) at 180 ° C, and then add the initiator (DCP) and graft monomer (MAH and AA) maleic anhydride unsaturated monomer After mixing evenly, a graft copolymer is obtained; continue to add SEBS, tackifying resin and antioxidant, melt and stir evenly, and finally add a viscosity regulator and vinyltrimethoxysilane or vinyltriethoxysilane, melt evenly, Adhesive resin is obtained from the discharge.

Embodiment 2

[0027] Adhesive resin for aluminum-plastic pipes (parts by mass):

[0028] High Density Polyethylene (HDPE)

[0029] Heat and stir through the reaction kettle, according to the above formula ratio, first heat and melt the matrix resin (HDPE, LLDPE) at 180 ° C, and then add the initiator (DCP) and graft monomer (MAH and AA) maleic anhydride unsaturated monomer After mixing evenly, a graft copolymer is obtained; continue to add SEBS, tackifying resin and antioxidant, melt and stir evenly, and finally add a viscosity regulator and vinyltrimethoxysilane or vinyltriethoxysilane, melt evenly, Adhesive resin is obtained from the discharge.

Embodiment 3

[0031] Adhesive resin for aluminum-plastic pipes (parts by mass):

[0032] High Density Polyethylene (HDPE)

12 copies

Linear Low Density Polyethylene (LLDPE)

35 copies

Dicumyl peroxide (DCP)

0.1 part

Maleic anhydride (MAH)

1 copy

Acrylic (AA)

0.5 parts

Vinyltrimethoxysilane or Vinyltriethoxysilane

7 copies

SEBS

2 copies

tackifying resin

40 copies

Viscosity modifier

18 copies

Antioxidants

0.3 parts

[0033] Heat and stir through the reaction kettle, according to the above formula ratio, first heat and melt the matrix resin (HDPE, LLDPE) at 180 ° C, and then add the initiator (DCP) and graft monomer (MAH and AA) maleic anhydride unsaturated monomer After mixing evenly, a graft copolymer is obtained; continue to add SEBS, tackifying resin and antioxidant, melt and stir evenly, and finally add a viscosity regulator and vinyltrimethoxysilane or vinyltriethoxysilane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com