Horizontal light-controlled water-cooled thyristor valve group

A technology of thyristor valves and thyristors, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of unsatisfactory heat dissipation consistency of components, inconsistent water pressure of component strings, uneven stress of thyristors, etc., and reduce skin effect , good contact, easy maintenance and replacement of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

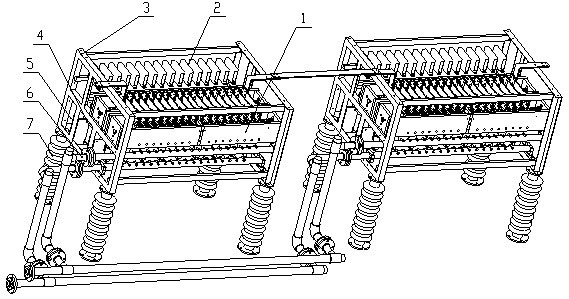

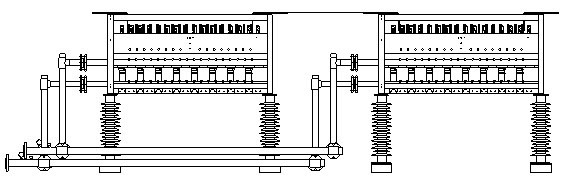

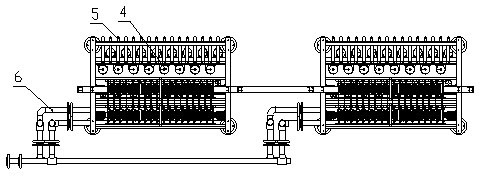

[0027] See Figure 1~Figure 4 , The light-controlled water-cooled thyristor valve group adopts a horizontal structure, and the left and right valve groups are connected in series to form a single-phase valve group. The soft copper bus bar is used to connect the left and right valve units. A single valve group adopts a horizontal structure, consisting of thyristor unit 1, trigger board unit 2, frame unit 3, RC protection capacitor unit 4, voltage equalizing resistor unit 5, water pipe unit 6, insulator unit 7, soft busbar 8, RC protection Water-cooled resistance unit 9 etc. are formed. The thyristor unit 1 that needs water cooling is arranged above the water pipe unit 6, the RC protection water cooling resistance unit 9 that needs water cooling is arranged behind the water pipe unit 6; the RC protection capacitor unit 4 that does not need water cooling is arranged in the RC protection water cooling resistance unit 9, the voltage equalizing resistance unit 5 is arranged on the...

Embodiment 2

[0030] See Figure 1~Figure 4 , A 35KV light-controlled water-cooled thyristor valve group is composed of a single valve group, and the valve group adopts a horizontal structure. It consists of thyristor unit 1, trigger board unit 2, frame unit 3, RC protection capacitor unit 4, voltage equalizing resistor unit 5, internal water pipe unit 6, insulator 7, soft busbar 8, RC protection water cooling resistance unit 9, etc. The thyristor unit 1 that requires water cooling is arranged above the internal water pipe, and the RC protection water-cooled resistance unit 9 that requires water cooling is arranged behind the internal water pipe; At the rear, the voltage equalizing resistance unit 5 is arranged on the epoxy cloth board under the rear and lower part of the valve unit, which is conducive to the heat dissipation of the voltage equalizing resistance unit 5. Due to the heat generated by the voltage equalizing resistance unit 5, the epoxy cloth board is isolated to avoid resistan...

Embodiment 3

[0032] Continue to increase the number of valve units on the basis of the original horizontal water-cooled light-controlled thyristor valve group to obtain a valve group with a higher voltage level.

[0033] The installation of the light-controlled thyristor and the water-cooled radiator of the horizontal valve group described in the present invention is completed by using a special press-fitting method, and the press-fitting method at least includes the following steps:

[0034] Step 1: Select two epoxy side pull plates and one intermediate pressure plate of appropriate size to form the H-shaped skeleton of the horizontal light-controlled thyristor valve group;

[0035] Step 2: Put the H-shaped framework vertically, install the required positioning pins, water-cooled radiators and light-controlled thyristors on the middle pressure plate of the H-shaped framework in sequence, and then install the alignment cake, press-fit components and pressure plate in sequence, and the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com