Temperature Compensation Circuit of Rectifier Diode in Flyback Converter

A technology of flyback converter and temperature compensation circuit, which is applied in the direction of converting DC power input to DC power output, instruments, electrical components, etc. Small chip area, improved integration, and increased reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

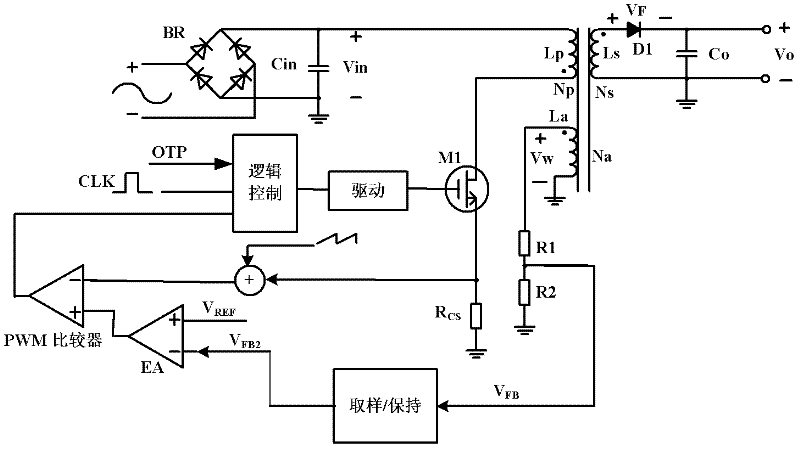

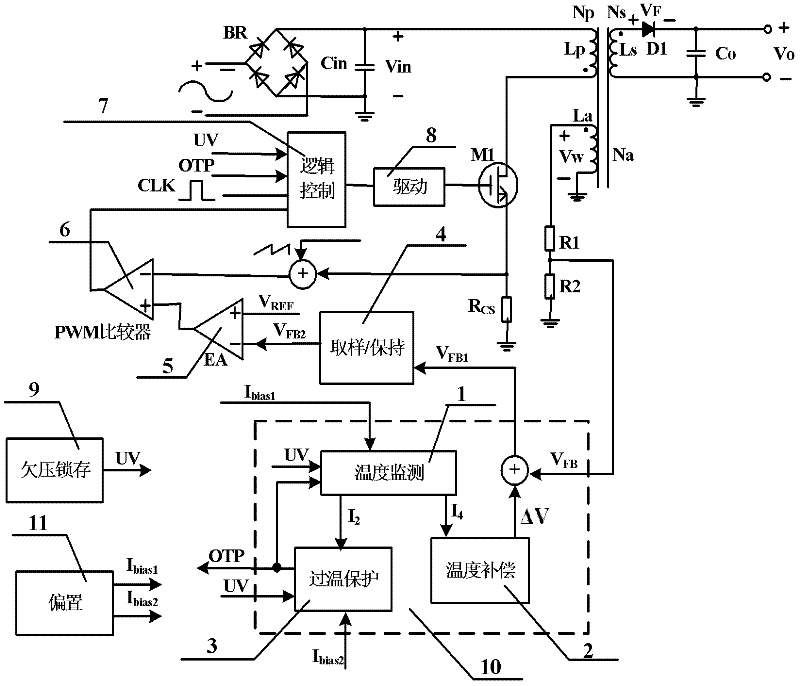

[0031] refer to image 3 , the primary side feedback flyback converter with the rectifier diode temperature compensation circuit of the present invention is mainly composed of a rectifier bridge BR, an input capacitor Cin and an output capacitor Co, a transformer primary side coil Lp with a number of turns Np, and a secondary side coil Ls, Its number of turns is Ns, auxiliary winding La, its number of turns is Na, secondary side rectifier diode D1, resistors R1 and R2, rectifier diode temperature compensation circuit 10, undervoltage lockout module 9, bias module 11, sample / hold Module 4, error amplifier EA5, PWM comparator 6, logic control module 7, drive module 8, power tube M1, and current sampling resistor R CS Composition; the undervoltage lockout module 9 outputs the undervoltage protection signal UV to the logic control module 7 and the rectifier diode temperature compensation circuit 10; the bias module 11 generates two constant bias currents I bias1 and I bias2 Inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com