Preparation method of cough-relieving tablets

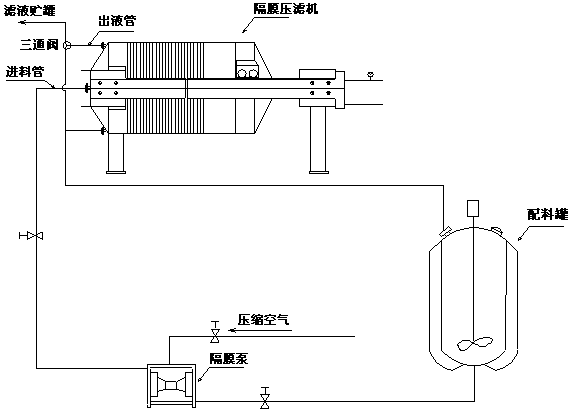

A technology of membrane pressure filtration and batching tank, which is applied to medical preparations containing active ingredients, pharmaceutical formulas, plant raw materials, etc. It can solve the problems of high extraction temperature, troublesome post-processing, and long extraction time, and reduce the loss of heat-sensitive ingredients. , The effect of improving the extraction efficiency and reducing the extraction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Prescription: Stemone 6.25kg, Peucedanum 6.25kg, bitter almond 3.125kg

[0041] The preparation method includes the following steps:

[0042] a. Extraction of Peucedanum

[0043] a1. Crush 70% of the prescription amount of Peucedanum chinensis into coarse powder for use;

[0044] a2. Add water equivalent to 7 times the weight of Qianhu coarse powder into the batching tank, heat it to 65℃ and keep it warm; switch the three-way valve to the batching tank position, turn on the agitator, diaphragm pump and diaphragm filter press of the batching tank, The water in the batching tank is pumped into the diaphragm filter press (80±10 L / m 2 .s polypropylene multifilament filter cloth), until the press filtrate flows back into the batching tank, add the powder obtained in step a1 to the batching tank at a constant speed, after the addition, the 65°C diaphragm filter press cycle is extracted for 30 minutes, and then the three-way valve is switched to Diaphragm pressure filtration is pe...

Embodiment 2

[0056] Prescription: Stemone 6.25kg, Peucedanum 6.25kg, bitter almond 3.125kg

[0057] The preparation method includes the following steps:

[0058] a. Extraction of Peucedanum

[0059] a1. Crush 70% of the prescription amount of Peucedanum chinensis into coarse powder for use;

[0060] a2. Add water equivalent to 6 times the weight of the coarse powder of Qianhu into the batching tank, heat it to 60℃ and keep it warm; switch the three-way valve to the batching tank position, turn on the agitator, diaphragm pump and diaphragm filter press of the batching tank, The water in the batching tank is pumped into the diaphragm filter press (80±10 L / m 2 .s polypropylene multifilament filter cloth), when the press filtrate flows back into the batching tank, add the powder obtained in step a1 to the batching tank at a constant speed, after the addition, the 60°C diaphragm filter press cycle extracts for 35 minutes, and then the three-way valve is switched to Diaphragm pressure filtration is ...

Embodiment 3

[0072] Prescription: Stemone 6.25kg, Peucedanum 6.25kg, bitter almond 3.125kg

[0073] The preparation method includes the following steps:

[0074] a. Extraction of Peucedanum

[0075] a1. Crush 70% of the prescription amount of Peucedanum chinensis into coarse powder for use;

[0076] a2. Add water equivalent to 8 times the weight of the coarse powder of Qianhu into the batching tank, heat it to 55℃ and keep it warm; switch the three-way valve to the batching tank position, turn on the agitator, diaphragm pump and diaphragm filter press of the batching tank, The water in the batching tank is pumped into the diaphragm filter press (80±10 L / m 2 .s polypropylene multifilament filter cloth), until the press filtrate flows back into the batching tank, add the powder obtained in step a1 to the batching tank at a constant speed, after the addition, 55°C diaphragm filter press cycle extraction for 40 minutes, then switch the three-way valve to Diaphragm pressure filtration is performed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com