A kind of preparation method of hydrotalcite hollow microsphere

A technology of hollow microspheres and hydrotalcites, which is applied in the preparation of microspheres and microcapsule preparations to achieve the effects of light weight, increased specific surface area, and large specific surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

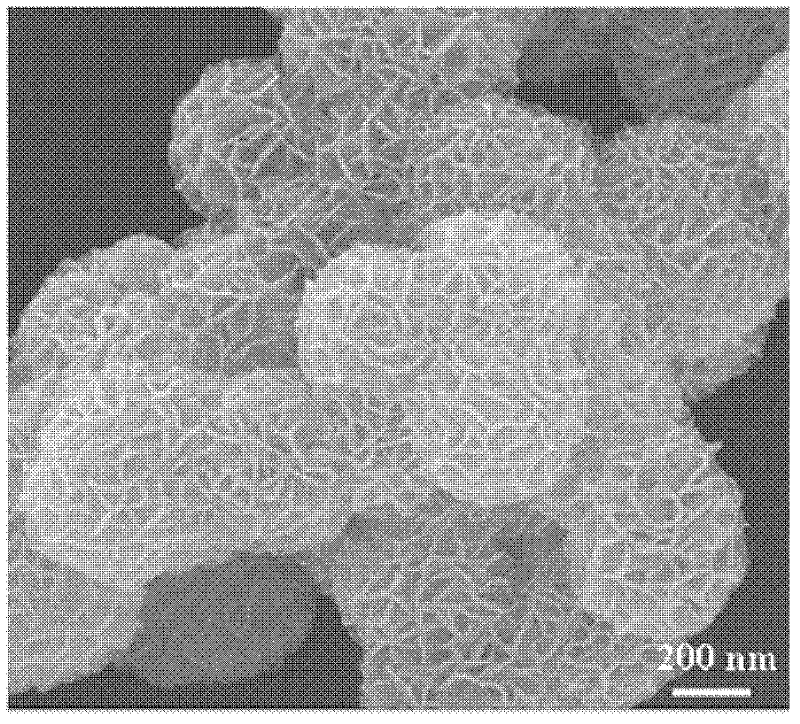

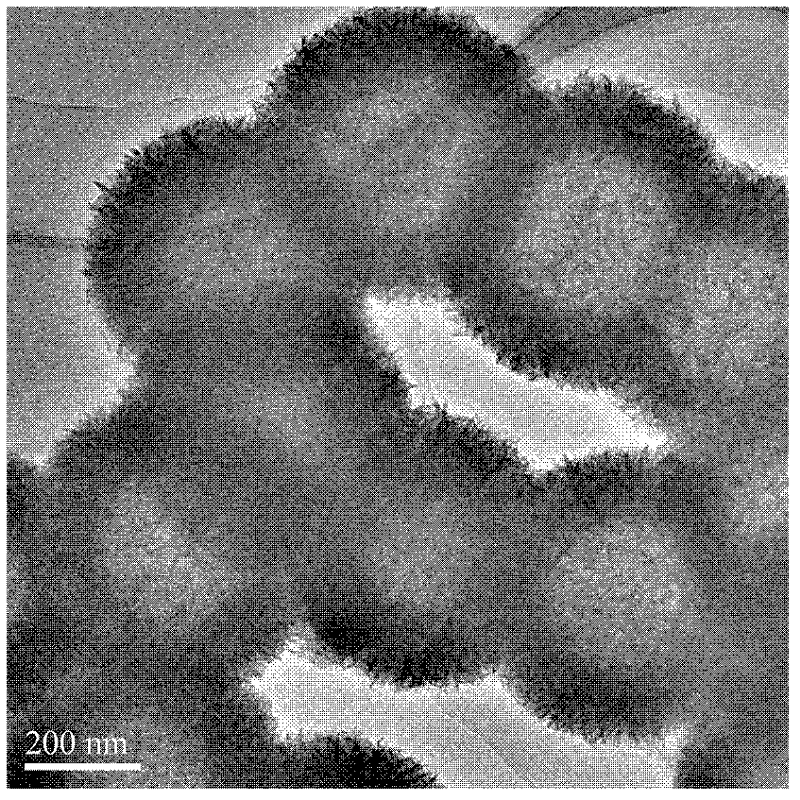

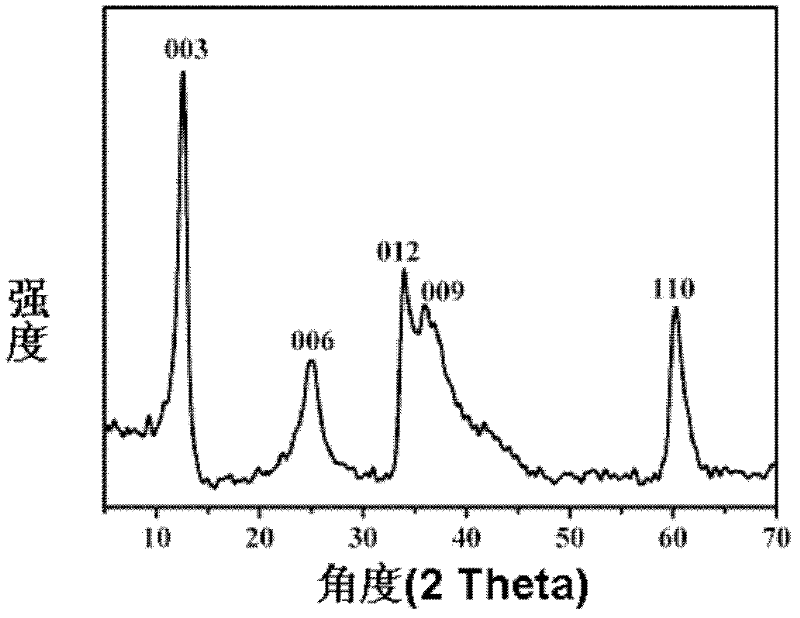

[0019] 1). Preparation of alumina monohydrate-coated silica microspheres:

[0020] a. Dissolve 11.5g of aluminum isopropoxide into 100ml of deionized water, stir at 85°C for 20 minutes, adjust the pH value to 3 with 1mol / L nitric acid, continue stirring for 2 hours, and then put it at room temperature for 5 days to Completely dry; add 5.8g of dried alumina monohydrate powder to 107ml of deionized water, stir at 85°C for 1 hour, add 9.5ml of 1mol / L nitric acid and continue stirring for 6 hours, then cool to room temperature to obtain monohydrate Alumina sol;

[0021] b. Add 8.5ml of tetraethyl orthosilicate, 18ml of deionized water and 98ml of ammonia water with a mass concentration of 25% into a three-necked flask containing 76ml of absolute ethanol, stir at room temperature for 4 hours, and then centrifugally wash with absolute ethanol until Neutral, dry at 60°C for 12 hours to obtain evenly dispersed silica microspheres;

[0022] c. Put 2 g of the silica microspheres obtai...

Embodiment 2

[0027] 1). Preparation of alumina monohydrate-coated silica microspheres:

[0028] a. Dissolve 10.2g of aluminum isopropoxide into 80ml of deionized water, stir at 80°C for 30 minutes, adjust the pH value to 3.5 with 0.8mol / L nitric acid, continue stirring for 3 hours, and then leave it at room temperature for 6 days until completely dry; add 5.5g of dried alumina monohydrate powder to 100ml of deionized water, stir at 80°C for 2 hours, add 10ml of 0.8mol / L nitric acid and continue stirring for 7 hours, then cool to room temperature to obtain a Hydrated alumina sol;

[0029] b. Add 8.1ml of tetraethyl orthosilicate, 15ml of deionized water and 90ml of ammonia water with a mass concentration of 20% into a three-necked flask containing 70ml of absolute ethanol, stir at room temperature for 4 hours, and then centrifugally wash with absolute ethanol until Neutral, dry at 70°C for 8 hours to obtain evenly dispersed silica microspheres;

[0030] c. Take 3g of the silica microspher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com