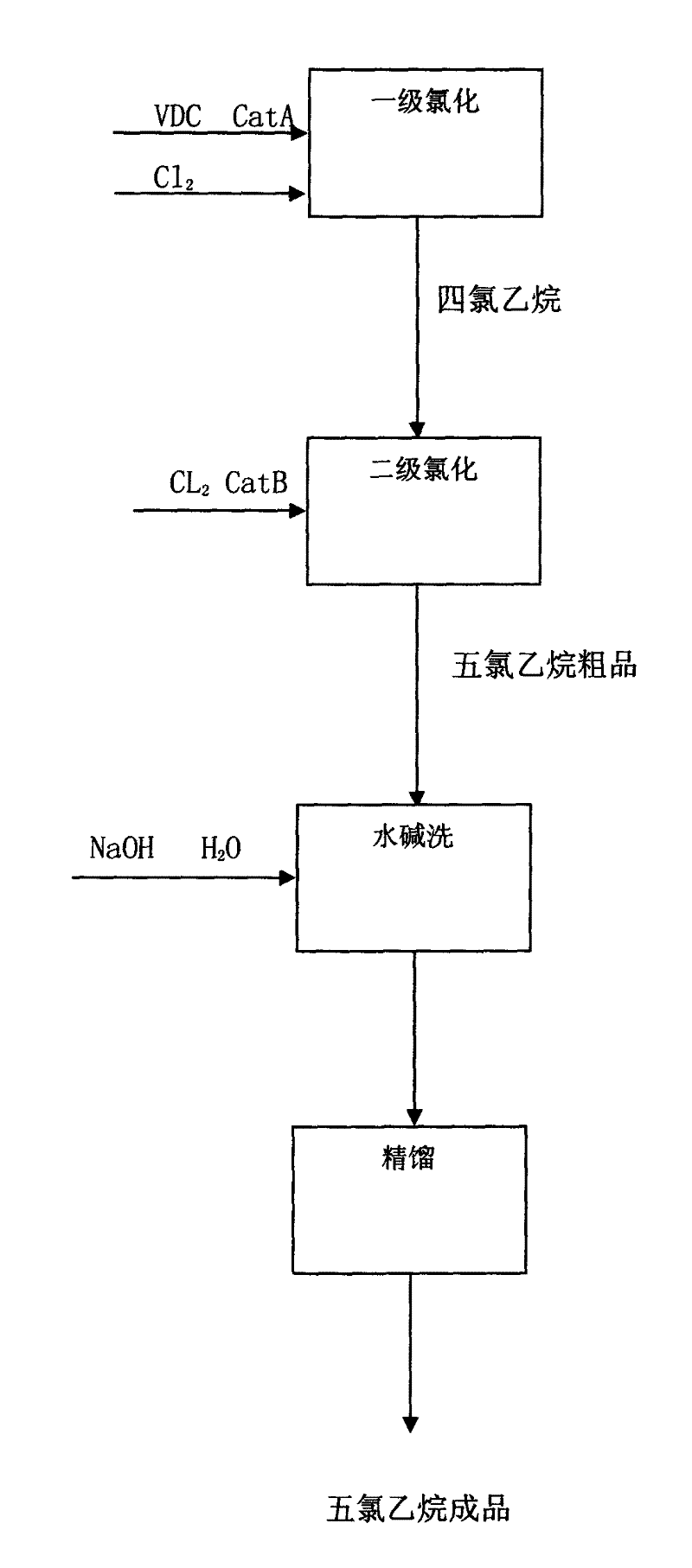

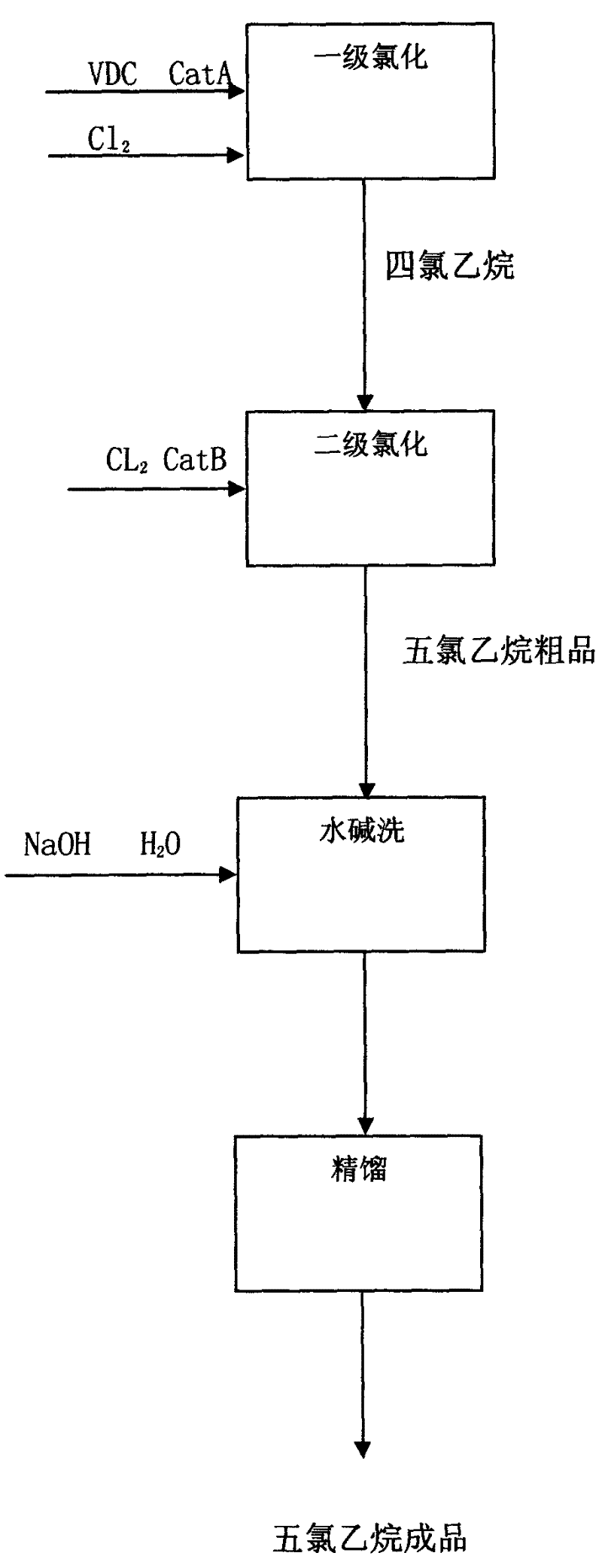

Method for preparing pentachloroethane by liquid phase chlorination of vinylidene chloride

A technology of vinylidene chloride and pentachloroethane is applied in the field of preparation of pentachloroethane, can solve the problems of high raw materials, high production cost, high production cost, poor economic benefit and the like, and achieves high material utilization rate, simple method, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In a 250ml four-necked flask, a chlorine inlet pipe, a reflux condenser, a thermometer and an electric stirrer are respectively installed, and 147ml (180 grams) of high-purity vinylidene chloride liquid is added into the flask from the feeding port, and the addition of a weight percentage is 80% ferric chloride, 20% cesium chloride, 0.9 gram of catalyst A mixed with 150~250 mesh solid powder, under stirring, feed into the tube from chlorine gas, lead to 2~3 kg / cm Pressure chlorine gas, and partial The molar ratio of vinyl chloride to chlorine gas is 1:1.1~1.4, the initial reaction temperature is 20~25°C, and the temperature is gradually raised to 70°C~80°C, and the prepared chlorinated liquid is tested once every two hours of reaction. When the content of vinyl chloride is less than 1%, the reaction of the first stage is terminated, the reaction time is 15.5 hours, and cooled to room temperature through a heat exchanger, then adding 75% aluminum chloride and 25% cesium c...

Embodiment 2

[0018] In the four-necked flask of 1000ml, respectively install chlorine inlet pipe, reflux condenser, thermometer and electric stirrer, add liquid vinylidene chloride liquid 590ml (700 grams) in the flask from the feeding port, and add the 75% by weight Ferric chloride, 15% antimony chloride, 10% cesium chloride, and 3.6 grams of catalyst A mixed with 150-250 mesh solid powder are passed into the tube from chlorine gas under stirring, and the pressure is 2-3 kg / cm 2 Chlorine under pressure, and the molar ratio of vinylidene chloride to chlorine is 1:1.1~1.4, the initial reaction temperature is 20~25°C, and the temperature is gradually raised to 65°C~75°C, and the reaction is detected once every two hours. Chlorinated liquid, when the content of vinylidene chloride is less than 1%, the first stage reaction is terminated, the reaction time is 17 hours, cooled to room temperature through a heat exchanger, and then added with 70% aluminum chloride, 15% Antimony chloride, 15% cesi...

Embodiment 3

[0020] at 10 meters 3 Drop into 7000 kilograms of liquid vinylidene chlorides in the chlorination reactor, add the ferric chloride of 75%, 25% cesium chloride, mix 35 kilograms of catalyst A with 150~250 purpose solid powders, under stirring from The chlorine gas inlet pipe is passed at 2 to 3 kg / cm 2 Chlorine under pressure, and the molar ratio of vinylidene chloride to chlorine is 1:1.1~1.4, the initial reaction temperature is 20~25°C, and the temperature is gradually raised to 75°C~less than 85°C, and the reaction time is detected once every two hours. The obtained chlorinated liquid, when the content of vinylidene chloride was less than 1%, was the termination of the first-stage reaction, and the reaction time was 20 hours, and was cooled to room temperature through a heat exchanger, and then adding weight percent was 80% aluminum chloride, Mix 10% antimony chloride and 10% cesium chloride with 150-250 mesh solid powder to form 35 kg of catalyst B, heat the reaction solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com