Polyether polyamine compound and synthesis method thereof as well as maintenance product for diesel motor fuel system

A diesel engine and polyether polyamine technology, which is applied in the field of diesel engine fuel system maintenance products and polyether polyamine compounds, can solve the problems of single function and inability to effectively remove carbon deposits, achieve obvious effects, increase maintenance time, The effect of improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

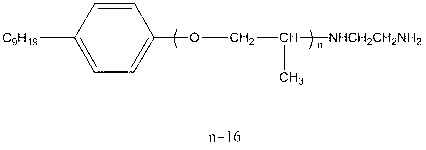

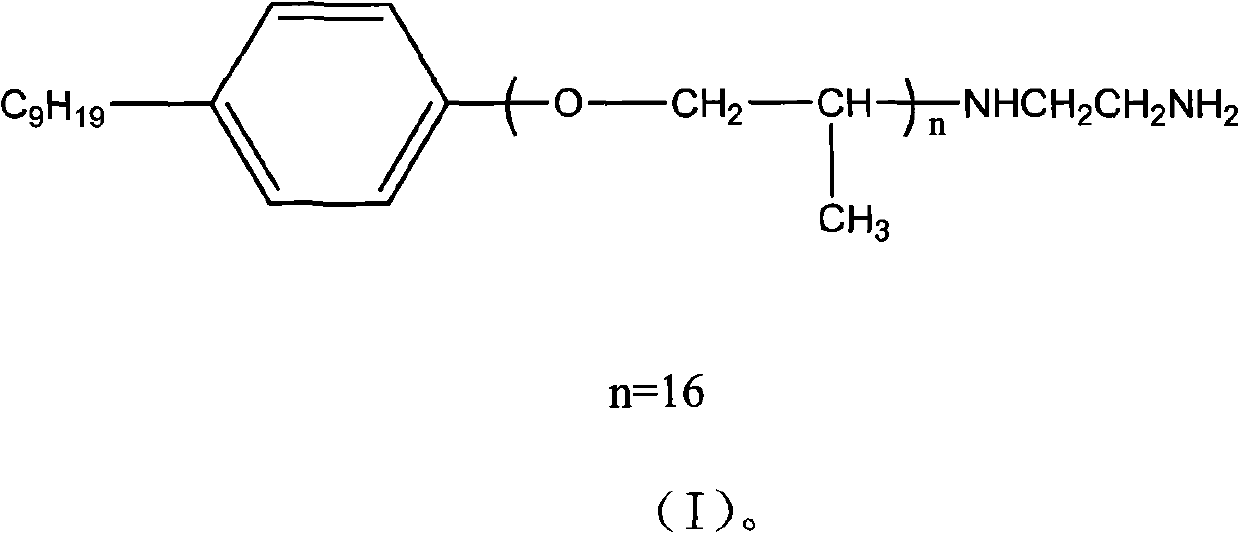

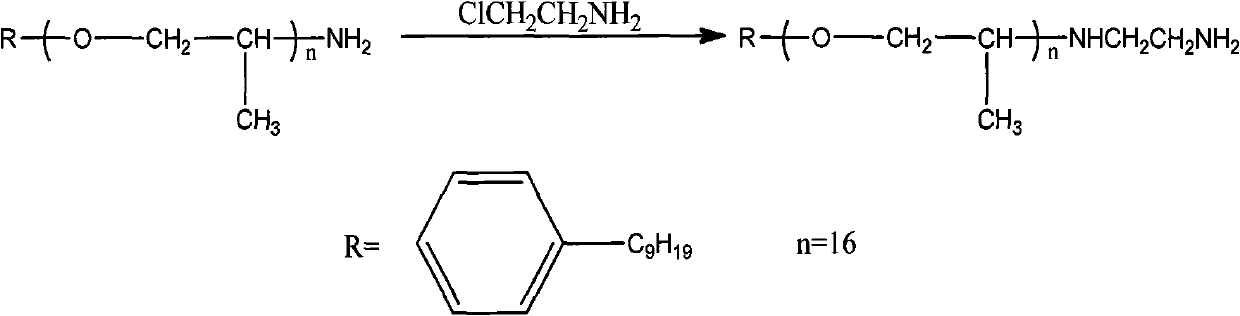

[0029] Preparation Example 1 [polyether polyamine compound (structural formula I)]:

[0030] Weigh 27.2.0g (about 0.1mol) of polyetheramine into a three-necked flask, then add a certain amount of triethylamine, and add 13.8g (about 0.12mol) of 2-chloroethylamine hydrochloride into the flask in batches. After the reaction was completed, the reaction liquid was distilled and purified under reduced pressure to obtain 28.8 g of the title compound - polyetherpolyamine, with a yield of 90%.

[0031] The product was analyzed by electrospray mass spectrometry, ESI-MS: 320.84 (measured value); 320.54 (calculated value).

[0032] Product is carried out infrared absorption spectroscopic test, survey result is as follows: 1) in 3400cm -1 There is a broad peak near it, which is caused by -NH stretching vibration; at 3000~2700cm -1 range has a set of steep and strong peaks, which are caused by -CH in the hydrocarbon chain 3 and -CH 2 Caused by stretching vibration; 3) at 1600~1200cm -1...

preparation Embodiment 2

[0033] Preparation Example 2 (maintenance product for diesel engine fuel system):

[0034]

[0035] Take the above-mentioned raw materials of formula quantity, fully mix and obtain target product.

preparation Embodiment 3

[0036] Preparation Example 3 (maintenance product for diesel engine fuel system):

[0037]

[0038] Take the above-mentioned raw materials of formula quantity, fully mix and obtain target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com