Long-chain branched polyester and preparation method thereof

A long-chain branched, polyester technology, applied in the field of polyester and its preparation, can solve the problems of affecting product performance, large difference in viscosity between polyester resin and chain extender, difficult to mix evenly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

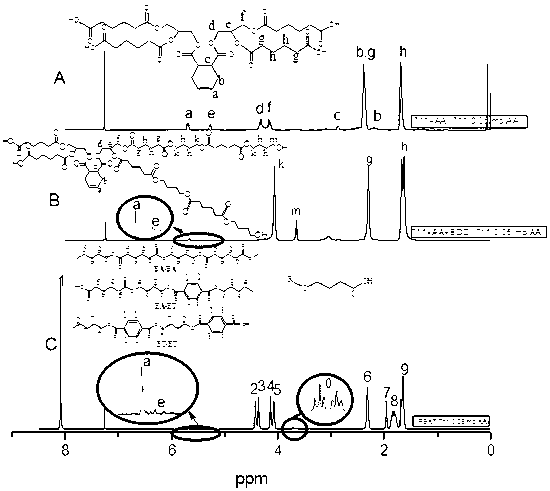

Image

Examples

Embodiment 1

[0053] Put 66.45 g of terephthalic acid and 61.28 g of 1,4-butanediol into a 250 mL four-neck flask, connect the condensation device and the mechanical stirring device, add the catalyst n-titanate 0.136 g, and heat in an oil bath at 220 o C, Esterification and dehydration for 3 h at a nitrogen rate of 0.5 L / min to obtain an aromatic-terminated hydroxyl ester product.

[0054]At the same time, 58.45 g of adipic acid, 54.03 g of 1,4-butanediol, 0.67 g of diglycidyl tetrahydrophthalate and 0.12 g of catalyst isopropyl titanate were placed at 180 o C, Esterification and dehydration for 3 h at a nitrogen rate of 0.5 L / min to obtain the aliphatic terminal hydroxyl esterification product.

[0055] Then transfer the products in the two flasks to a 500 mL four-neck flask, connect the condensing device and the mechanical stirring device, add 0.5 g of rare earth catalyst lanthanum acetylacetonate, and gradually raise the oil temperature to 260 o C, the pressure gradually decreased to 3...

Embodiment 2

[0057] Put 68.87 g of 1,4-cyclohexanedicarboxylic acid and 70.90 g of 1,6-hexanediol into a 250 mL four-neck flask, connect the condensing device and mechanical stirring device, and heat the oil bath at 195 o C, Esterification and dehydration for 3 h at a nitrogen rate of 0.5 L / min to obtain an alicyclic hydroxyl-terminated esterification product.

[0058] At the same time, 47.24 g succinic acid, 70.90 g 1,6-hexanediol, 3.35 g glycidol and catalyst butyl titanate 0.12 g were placed at 180 o C, Esterification and dehydration for 3 h at a nitrogen rate of 0.5 L / min to obtain the aliphatic terminal hydroxyl esterification product.

[0059] The operation steps in the copolymerization stage were as in Example 1, and a copolyester with a weight average molecular weight of 145,000 was obtained, and the product was white and slightly yellowed.

Embodiment 3

[0061] Put 62.4 g of 2,5-furandicarboxylic acid and 61.28 g of 1,4-butanediol into a 250 mL four-neck flask, connect the condensing device and the mechanical stirring device, add the catalyst 0.136 g of butyl titanate, and put it in an oil bath Heating at 180 o C, Esterification and dehydration for 3 h at a rate of nitrogen in and out of 0.5 L / min to obtain a heterocyclic hydroxyl-terminated esterification product.

[0062] At the same time, 58.45 g of adipic acid, 54.03 g of butanediol, 0.67 g of diglycidyl terephthalate and 0.12 g of catalyst isopropyl titanate were placed in 180 o C, Esterification and dehydration for 3 h at a nitrogen rate of 0.5 L / min to obtain the aliphatic terminal hydroxyl esterification product.

[0063] The operation steps in the copolymerization stage were as in Example 1, and a copolyester with a weight average molecular weight of 130,000 was obtained, and the product was white and slightly yellowed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com