Preparation method of density-controllable colorful electrophoresis particle for electronic paper

A technology for color electrophoresis and electronic paper, applied in instruments, optics, nonlinear optics, etc., can solve the problems that electrophoretic particles cannot be closely arranged, affect the service life of electrophoretic particles, and reduce the display quality of electronic paper, and achieve rich surface charge, color and luster. Vivid, mass-produced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

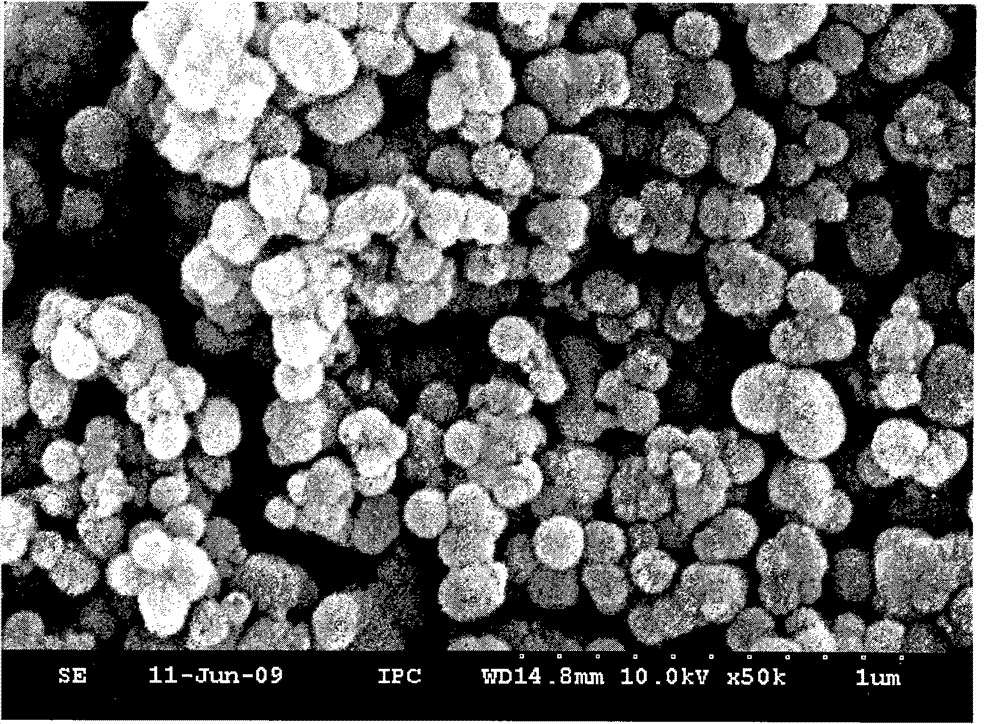

Image

Examples

Embodiment 1

[0035] (1) In the reactor, sodium dodecylbenzenesulfonate is dissolved and dispersed in water to obtain sodium dodecylbenzenesulfonate solution, wherein the initial concentration of sodium dodecylbenzenesulfonate in water is 6g / L;

[0036] (2) Add nano-pigment blue 15 particles into the styrene monomer, and then perform ultrasonication in an ultrasonic device for 10 minutes, so that the nano-pigment blue 15 particles are uniformly dispersed in the styrene monomer to obtain a dispersion liquid, wherein the nano-pigment blue 15 The concentration in styrene monomer is 50g / L;

[0037] (3) the dispersion liquid that step (2) obtains is joined in the sodium dodecylbenzenesulfonate solution that step (1) obtains, and the dispersion liquid that step (2) obtains and the dodecylbenzene that step (1) obtains The volume ratio of sodium benzenesulfonate solution is 1: 25, carries out supersonic emulsification in sonicator, forms the styrene miniemulsion that comprises nano pigment blue 1...

Embodiment 2

[0043] (1) In the reactor, sodium dodecylbenzenesulfonate is dissolved and dispersed in water to obtain sodium dodecylbenzenesulfonate solution, wherein the initial concentration of sodium dodecylbenzenesulfonate in water is 20g / L;

[0044] (2) Add the nano-pigment green 7 particles into the styrene monomer, and then perform ultrasonication in an ultrasonic device for 10 minutes, so that the nano-pigment green 7 particles are uniformly dispersed in the styrene monomer to obtain a dispersion liquid, wherein the nano-pigment green 7 The concentration in styrene monomer is 1g / L;

[0045] (3) the dispersion liquid that step (2) obtains is joined in the sodium dodecylbenzenesulfonate solution that step (1) obtains, and the dispersion liquid that step (2) obtains and the dodecylbenzene that step (1) obtains The volume ratio of sodium benzenesulfonate solution is 1: 6, carries out supersonic emulsification in sonicator, forms the styrene miniemulsion that comprises nano-pigment gre...

Embodiment 3

[0052] (1) In the reactor, sodium dodecylbenzenesulfonate is dissolved and dispersed in water to obtain sodium dodecylbenzenesulfonate solution, wherein the initial concentration of sodium dodecylbenzenesulfonate in water is 1g / L;

[0053] (2) Add the nano-pigment white 6 particles to the styrene monomer, and then perform ultrasonication in an ultrasonic device for 10 minutes, so that the nano-pigment white 6 particles are uniformly dispersed in the styrene monomer to obtain a dispersion liquid, wherein the nano-pigment white 6 The concentration of particles in styrene monomer is 200g / L;

[0054] (3) the dispersion liquid that step (2) obtains is joined in the sodium dodecylbenzenesulfonate solution that step (1) obtains, and the dispersion liquid that step (2) obtains and the dodecylbenzene that step (1) obtains The volume ratio of sodium benzenesulfonate solution is 1: 400, carries out supersonic emulsification in ultrasonic machine, forms the styrene miniemulsion that com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com