SiOC ceramic material used for preparing cathode of lithium ion battery, preparation method thereof and lithium ion battery

A technology for lithium ion batteries and ceramic materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing the cycle performance of silicon materials, poor silicon conductivity, and material structure collapse, and achieve good cycle performance and stable performance. , the effect of increasing the capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

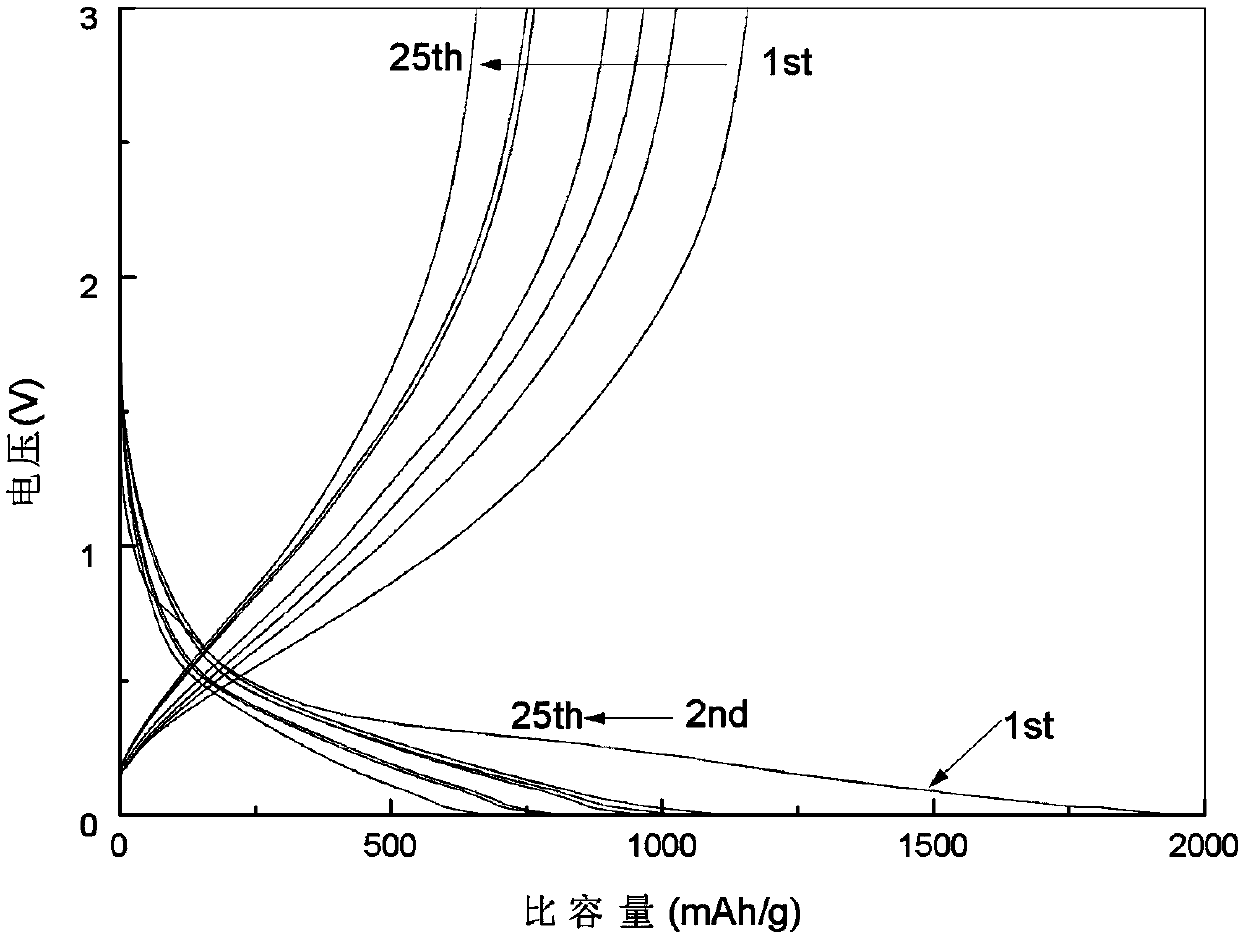

Embodiment 1

[0046] The SiOC ceramic material used to prepare the lithium-ion battery negative electrode in this embodiment is prepared by the following steps:

[0047] (1) Prepare the precursor: prepare 50 g of polysiloxane and 50 g of divinylbenzene; the molecular formula of the polysiloxane is CH 3 (Si(H)(CH 3 )O) 0.22 (Si(CH 3 ) 2 O) 0.12 (Si(OH)(CH 3 )O) 0.66 CH 3 . There are two vinyl groups in the molecular formula of divinylbenzene, which can react with silicon hydrogen groups in polysiloxane to form a copolymer.

[0048] (2) Cross-linking curing: Mix 50 g of polysiloxane and 50 g of divinylbenzene, add 100 mL of toluene solvent, mix evenly, and then remove the solvent in a rotary evaporator (the temperature is controlled at 100 °C), and wait for After the toluene evaporated, the samples were taken out and dried in a vacuum oven for 2 h. Then 5 ppm of chloroplatinic acid was added as a catalyst, mixed evenly and placed in an oven at 200 °C for 4 h, the sample was finally ...

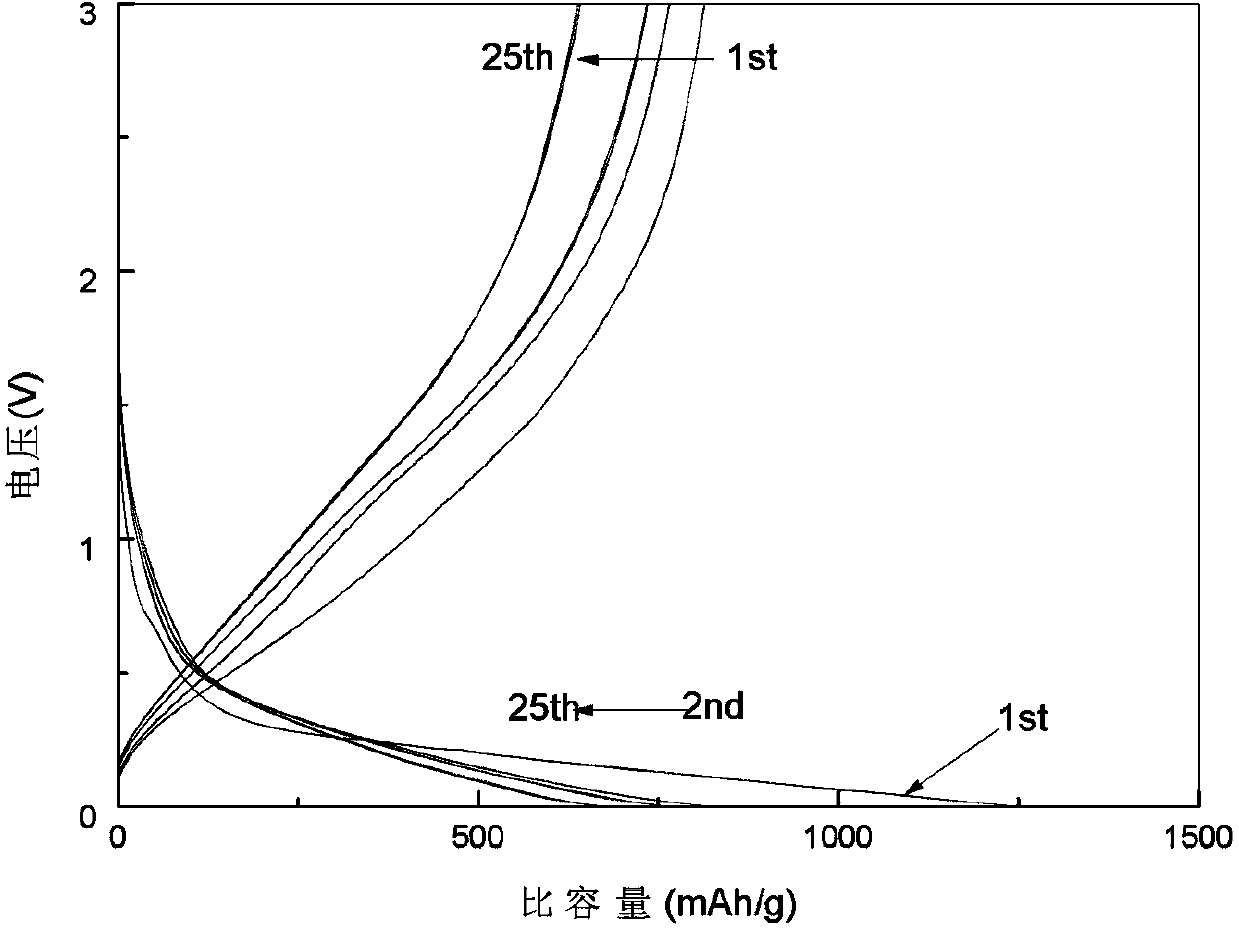

Embodiment 2

[0062] The SiOC ceramic material used to prepare the lithium-ion battery negative electrode in this embodiment is prepared by the following steps:

[0063] (1) Prepare the precursor: prepare 50 g of polysiloxane and 50 g of polystyrene. The molecular formula of the polysiloxane is CH 3 (Si(H)(CH 3 )O) 0.33 (Si(C 6 h 5 )(CH 3 )O) 0.25 (Si(OC 3 h 7 ) 2 O) 0.42 CH 3 ; The main chain of polystyrene is a saturated carbon chain and contains vinyl, which can react with the silicon hydrogen group in polysiloxane to form a copolymer.

[0064] (2) Cross-linking curing: Mix 50 g of polysiloxane and 50 g of polystyrene, add 100 mL of toluene solvent, mix evenly, and then put it in a rotary evaporator to remove the solvent (the temperature is controlled at 100 ℃), and wait for After the toluene evaporated, the samples were taken out and dried in a vacuum oven for 2 h. Then add 2wt% benzoyl peroxide (Bengbu Jiaxian Chemical Co., Ltd.) as a catalyst, mix well and place it in an o...

Embodiment 3

[0078] The SiOC ceramic material used to prepare the lithium-ion battery negative electrode in this embodiment is prepared by the following steps:

[0079] (1) Prepare the precursor: prepare 50g of polysiloxane and 50g of polyethylene. The molecular formula of the polysiloxane is CH 3 (Si(H)(CH 3 )O) 0.30 (Si(C 6 h 5 )(CH 3 )O) 0.32 (Si(CHCH 2 )(CH 3 )O) 0.38 CH 3 ; Polyethylene contains vinyl groups, which can react with silicon hydrogen groups and vinyl groups in polysiloxane to form copolymers.

[0080] (2) Cross-linking curing: Mix polysiloxane with 50 g, polyethylene 50 g and graphite powder 10 g (filler), add 100 mL of toluene solvent, mix evenly, and then remove the solvent in a rotary evaporator (temperature controlled at 100 °C), after the toluene evaporated, the sample was taken out and dried in a vacuum oven for 2 h. Then 2wt% benzoyl peroxide (Bengbu Jiaxian) was added as a catalyst, mixed evenly and placed in an oven at 250°C for 3 h, the sample was fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com