Coated cysteamine hydrochloride and preparation method thereof

A cysteamine hydrochloride, coating technology, applied in the coating of cysteamine hydrochloride, the preparation of the coated cysteamine hydrochloride, the field of physiological regulation, to achieve food safety, promote growth, improve meat color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

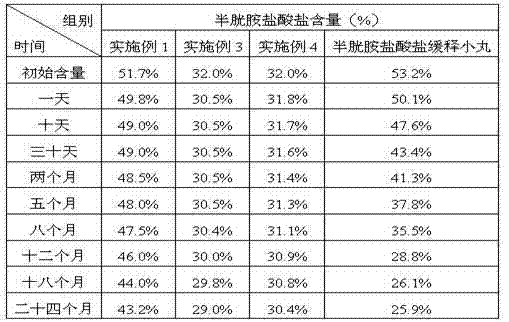

Embodiment 1

[0033] A coated cysteamine hydrochloride, consisting of the following components by weight:

[0034] 35 parts of cysteamine hydrochloride, 13 parts of stearic acid, 12 parts of cellulose aqueous solution with a methylcellulose content of 5 wt%, 4.5 parts of citric acid, and 32 parts of white carbon black. The initial content of cysteamine hydrochloride was 51.7%.

[0035] Preparation:

[0036] The first step: Production preparation: 1. Dissolve 5 wt% of cellulose in warm water at 60-70°C 48 hours in advance, and stir frequently to fully dissolve it to form a cellulose aqueous solution; 2. Add stearic acid Heating and melting into a liquid state for use; 3. Breaking the massive cysteamine hydrochloride into moderately small pieces;

[0037] The second step: Grinding process: Weigh various raw materials according to the ratio in the formula, and add them to the colloid mill for grinding in the order of stearic acid - cellulose aqueous solution - cysteamine hydrochloride - citr...

Embodiment 2

[0041] A coated cysteamine hydrochloride, consisting of the following components by weight:

[0042] 29 parts of cysteamine hydrochloride, 17 parts of stearic acid, 14 parts of cellulose aqueous solution with a methylcellulose content of 5 wt%, 5.5 parts of citric acid, and 38 parts of white carbon black. The initial content of cysteamine hydrochloride was 28%.

[0043] The preparation method is the same as in Example 1.

Embodiment 3

[0045] A coated cysteamine hydrochloride, consisting of the following components by weight:

[0046] 32 parts of cysteamine hydrochloride, 15 parts of stearic acid, 13 parts of cellulose aqueous solution with a methylcellulose content of 5 wt%, 5 parts of citric acid, and 35 parts of white carbon black. The initial content of cysteamine hydrochloride was 32%.

[0047] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com