Three-dimensional cell dynamic culture reactor

A dynamic culture and cell culture technology, applied in the field of cell culture liquid culture equipment, can solve the problems of not being able to provide cell temperature, humidity and gas conditions, single function, easy to contaminate, etc., to shorten the cell culture time, simplify the process, reduce The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

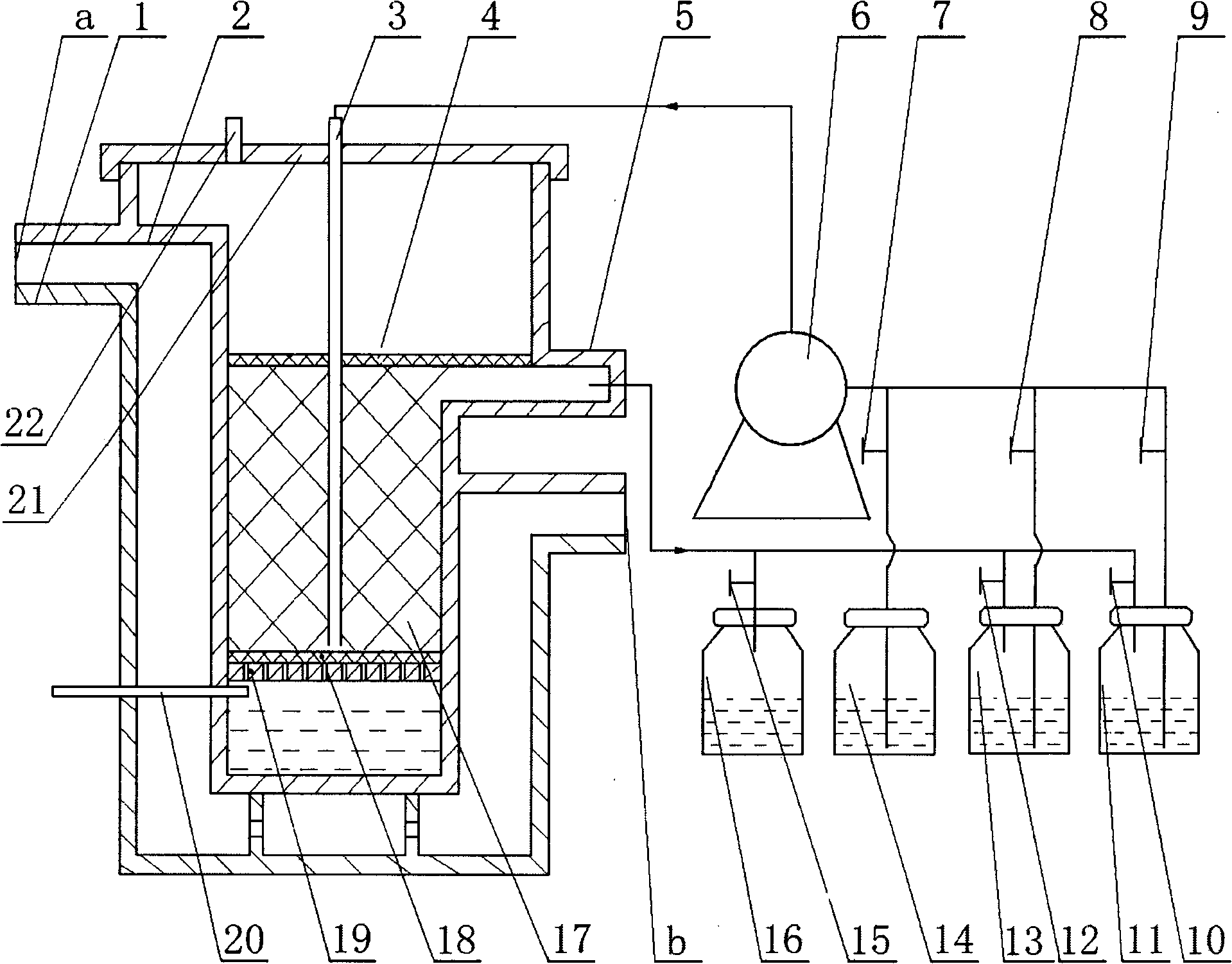

[0018] exist figure 1 Among them, the three-dimensional cell dynamic culture reactor of this embodiment is composed of a reactor outer shell 1, a reactor inner shell 2, a liquid inlet pipe 3, an upper waterproof and breathable membrane 4, a liquid outlet pipe 5, a peristaltic pump 6, and a buffer valve 7. Cell culture fluid outlet valve 8, cell suspension fluid outlet valve 9, cell suspension fluid inlet valve 10, cell suspension bottle 11, cell culture fluid inlet valve 12, cell culture fluid bottle 13, buffer bottle 14 , waste liquid valve 15, waste liquid bottle 16, cell culture support 17, lower waterproof breathable membrane 18, support plate 19, air inlet pipe 20, sealing loam cake 21, air outlet one-way valve 22 connection forms.

[0019] A reactor inner shell 2 is installed in the reactor outer shell 1, and the shape of the reactor outer shell 1 and the reactor inner shell 2 is cylindrical, and the reactor outer shell 1 and the reactor inner shell 2 are made of plexigl...

Embodiment 2

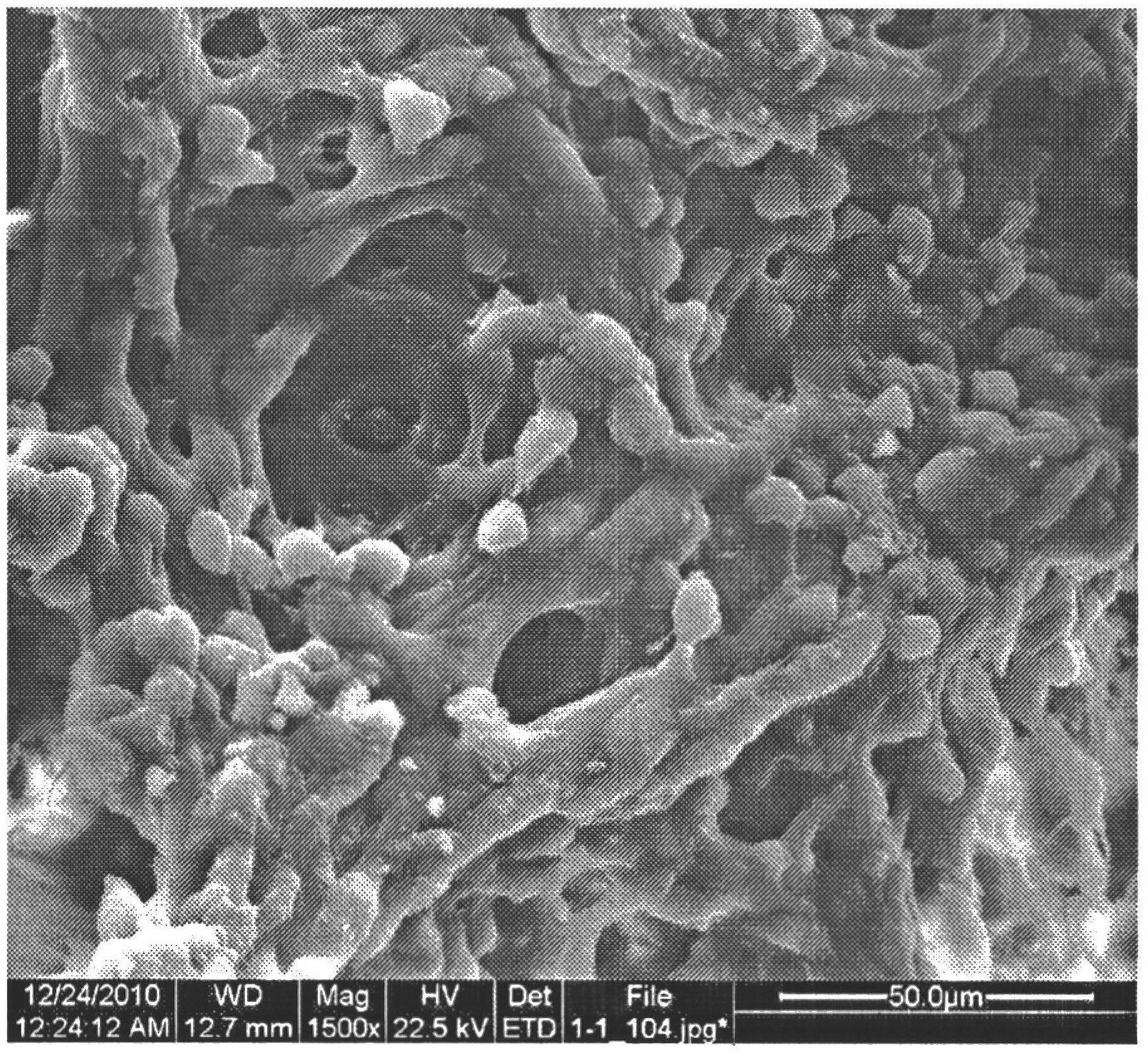

[0028] In this embodiment, a lower waterproof and gas-permeable membrane 18 is placed on the support plate 19 in the reactor inner casing 2, and the upper part of the lower waterproof and gas-permeable membrane 18 of the reactor inner casing 2 is equipped with a cell culture support 17. The culture support 17 adopts a chitosan / hydroxyapatite three-dimensional porous support, which was prepared by the inventors. Other components and the coupling relationship of the components are the same as in Embodiment 1.

[0029] The preparation method of chitosan / hydroxyapatite three-dimensional porous scaffold is as follows:

[0030] 1. Dissolving chitosan and hydroxyapatite

[0031] Dissolve 1g chitosan (deacetylation degree is 80%~95%), 0.1g hydroxyapatite in the acetic acid aqueous solution of 100mL 20g / L, stir for 6 hours, centrifuge to remove air bubbles, obtain chitosan and hydroxyapatite stone mixture.

[0032] 2. Preparation of chitosan / hydroxyapatite three-dimensional porous c...

Embodiment 3

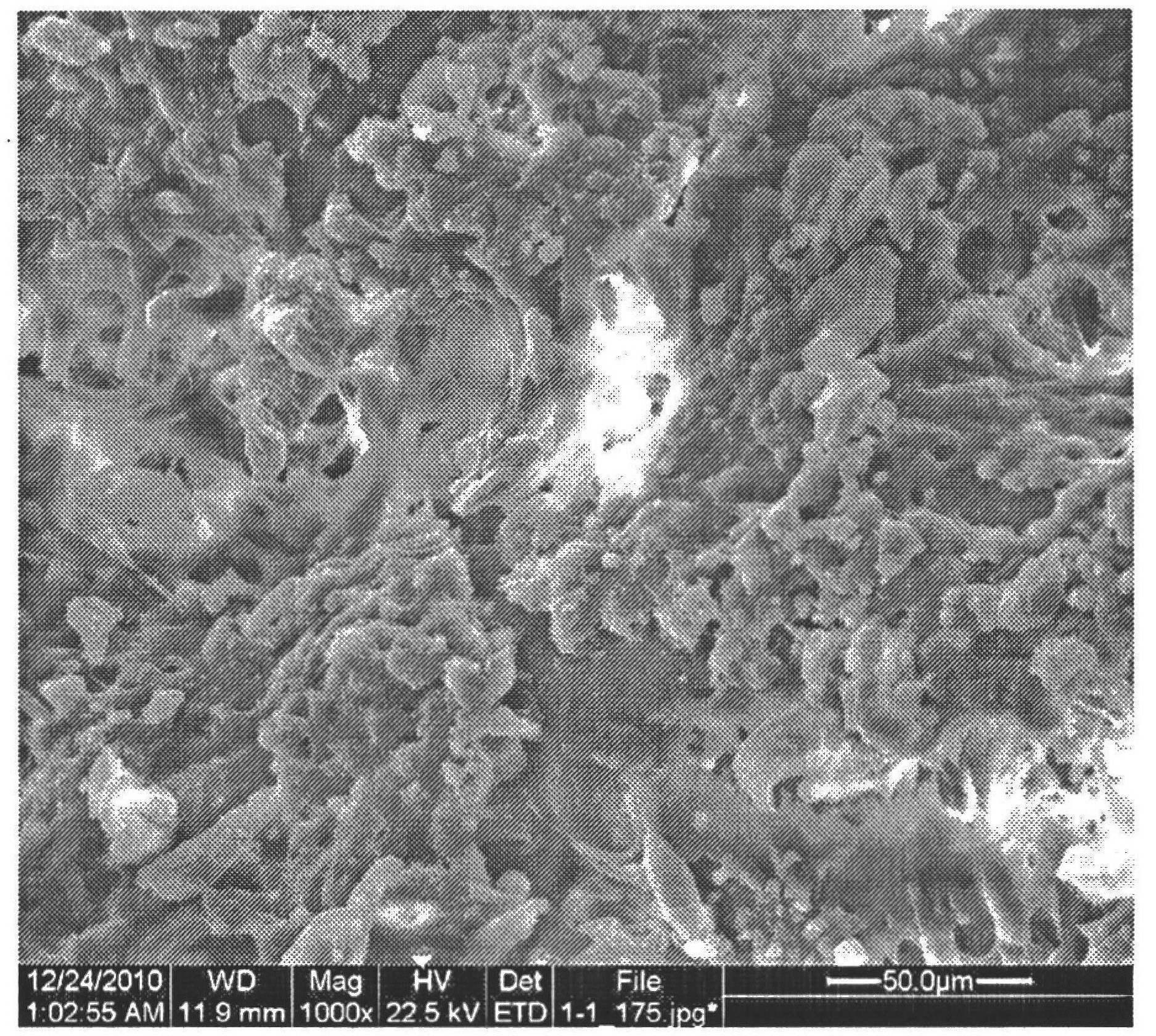

[0035] In this embodiment, a lower waterproof and gas-permeable membrane 18 is placed on the support plate 19 in the reactor inner casing 2, and the upper part of the lower waterproof and gas-permeable membrane 18 of the reactor inner casing 2 is equipped with a cell culture support 17. The culture support 17 is polylactic acid-polyglycolic acid copolymer / hydroxyapatite / collagen composite porous scaffold, which was prepared by the inventors. Other components and the coupling relationship of the components are the same as in Embodiment 1.

[0036] Taking the preparation of 100 g of polylactic acid-polyglycolic acid copolymer / hydroxyapatite / collagen composite porous scaffold as an example, the raw materials used and their proportions are:

[0037] Polylactic acid-polyglycolic acid copolymer 95g

[0038] Hydroxyapatite 2.5g

[0039] Collagen 2.5g

[0040] Its preparation method is as follows:

[0041] Take 95g of polylactic acid-polyglycolic acid copolymer, 2.5g of hydroxyapa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com