Cross-linked enzyme aggregate prepared in water-in-oil emulsion and preparation method thereof

A technology of water-in-oil emulsion and enzyme aggregates, applied in the field of biochemical industry, can solve the problems of affecting the activity of cross-linked enzyme aggregates, not easy to disperse, large in size, etc. High enzymatic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: the selection of precipitation agent

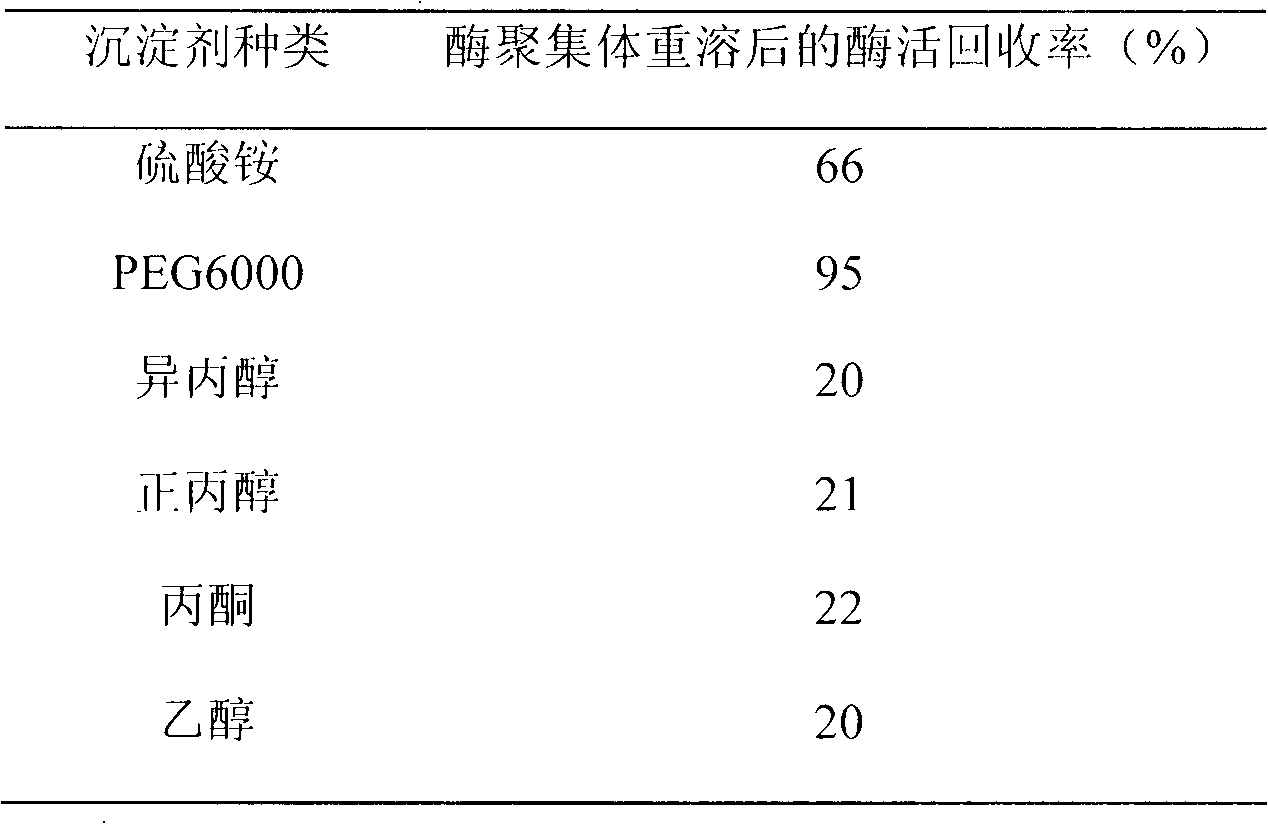

[0043] Prepare trehalose synthase solution with 50mmol / L, pH7.0 phosphate buffer solution, take 6 parts of the trehalose synthase solution, each 1mL, add saturated ammonium sulfate, PEG6000 with a concentration of 30%, isopropanol, 9 mL each of n-propanol, acetone and ethanol, carry out aggregation and precipitation, regularly sample and centrifuge, measure the protein content of the supernatant until about 90% of the protein is precipitated, centrifuge to collect the precipitated enzyme aggregates, and wash the enzyme aggregates with phosphate buffer solution After redissolving, the enzyme activity was measured, and the recovery rate of the enzyme activity was calculated. The results are shown in Table 1.

[0044] Table 1 Effect of precipitant on enzyme activity

[0045]

[0046] It can be seen from Table 1 that using PEG6000 as the precipitating agent has little effect on the activity of trehalose synthase, so P...

Embodiment 2

[0050] Example 2: Preparation of cross-linked enzyme aggregates in water-in-oil emulsion

[0051] Step 1: Prepare trehalose synthase solution with 50mmol / L, pH7.0 phosphate buffer;

[0052] Step 2: Take 10mL of trehalose synthase solution, gradually add 3g of PEG6000, stir or oscillate, after PEG6000 dissolves, put it in a shaker at 25°C and 150r / min, and the mixture obtained after 30min is used as the dispersed phase containing enzyme;

[0053] Step 3: Add 2 mL of 25% glutaraldehyde to the enzyme-containing dispersed phase obtained in Step 2, then add 50 mL of mineral oil, and emulsify with a homogeneous emulsifier at 10,000 r / min for 1 min to form a water-in-oil emulsion;

[0054] Step 4: Stir the water-in-oil emulsion formed in Step 3 at 25°C and 1000r / min for 1h;

[0055] Step 5: After stirring, the emulsion was centrifuged at 10,000 r / min for 10 min, and the precipitate was recovered to obtain cross-linked enzyme aggregates.

Embodiment 3

[0056] Embodiment 3: add emulsifier

[0057] Step 1: Prepare trehalose synthase solution with 50mmol / L, pH7.0 phosphate buffer;

[0058] Step 2: Take 1mL of trehalose synthase solution, gradually add 0.25g of PEG6000, stir or oscillate to dissolve and mix the PEG6000, and the resulting mixture is used as the dispersed phase containing the enzyme;

[0059] Step 3: Add 0.2 g of Span60 to 20 mL of soybean oil, mix well, add it to the dispersed phase containing enzyme obtained in Step 2, stir and emulsify at 1500 r / min for 1 min, and form a water-in-oil emulsion;

[0060] Step 4: Add 20 μL of 25% glutaraldehyde to the water-in-oil emulsion formed in step 3, stir at 1500 r / min for 5 minutes, and then stand at 25°C for 2 hours for cross-linking;

[0061] Step 5: After cross-linking, the emulsion was centrifuged at 3000 r / min for 20 min, and the obtained precipitate was centrifuged and washed 3 times with 10 mmol / L, pH 7.0 phosphate buffer to obtain cross-linked enzyme aggregates. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com