Electrolyte solution of lithium ion battery

A lithium-ion battery, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of battery performance degradation, limited low temperature performance, poor low temperature performance, etc., to improve discharge performance, improve high and low temperature performance , the effect of good discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

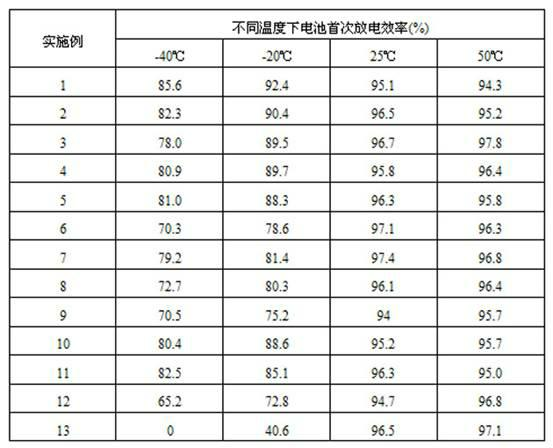

Examples

Embodiment 1

[0016] Select 60% cyclic carboxylate gamma-butyrolactone, 40% linear carboxylate for use in the present embodiment, wherein, ethyl acetate, ethyl propionate each get 20%, the content of described film-forming additive accounts for 0.5% of the total weight of the solvent and the lithium salt.

Embodiment 2

[0018] Select 80% cyclic carboxylate gamma-butyrolactone, 20% linear carboxylate for use in the present embodiment, wherein, ethyl acetate, ethyl propionate each get 10%, the content of described film-forming additive accounts for 1.5% of the total weight of the solvent and the lithium salt.

Embodiment 3

[0020] Select 90% cyclic carboxylate gamma-butyrolactone, 10% linear carboxylate for use in the present embodiment, wherein, ethyl acetate, ethyl propionate each get 5%, the content of described film-forming additive accounts for 3% of the total weight of the solvent and the lithium salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com