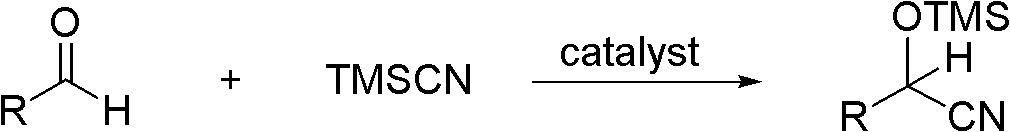

Highly active catalyst used for hydrosilation reaction of aldehyde and trimethylsilyl cyanide

A technology of trimethylsilyl cyanide and high-activity catalysts, which is applied in the field of high-activity catalysts, can solve the problems of using organic solvent reaction conditions, large amount of catalysts, nonconformities, etc., and achieves wide application range, simple operation, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

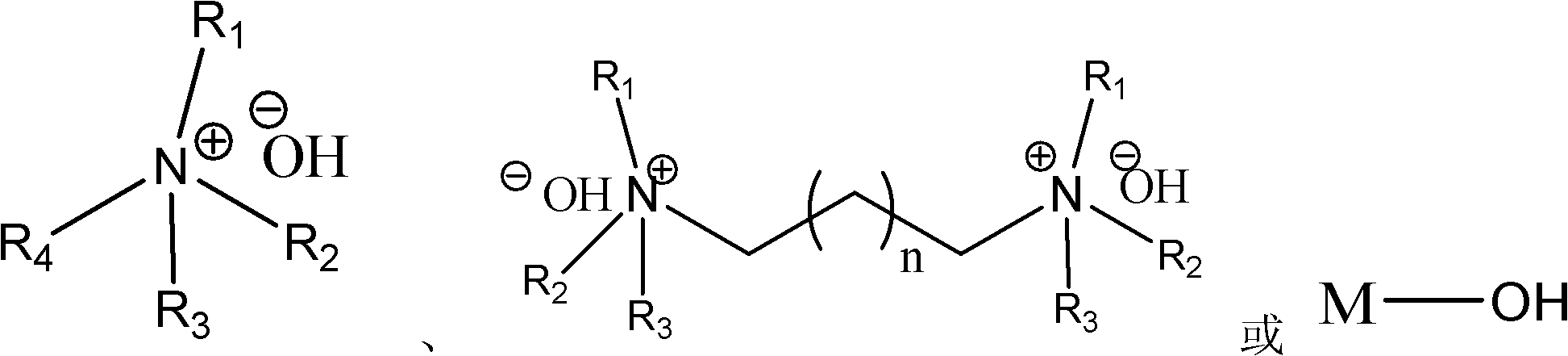

Method used

Image

Examples

Embodiment 1

[0020] Preparation of isobutyraldehyde cyanohydrin siloxane

[0021] Add 2.3mL (0.025mol) of freshly distilled isobutyraldehyde to a 25mL one-necked flask, and then add 0.46μL (5.0×10 -8 mol) with a mass fraction of 1% (CH 3 ) 4 Add 3.4mL (0.025mol) trimethylsilyl cyanide (the molar ratio of catalyst, isobutyraldehyde and trimethyl silyl cyanide is 1: 500000: 500000) to the NOH aqueous solution with stirring at room temperature, the reaction is violent (Note : The heat released in the reaction is released naturally by itself), and the reaction ends in 10 minutes. 1 The conversion was determined to be 100% by H NMR.

Embodiment 2

[0023] Preparation of Benzaldehyde Cyanohydrin Silicon Ether

[0024] Add 53g (0.5mol) of freshly distilled benzaldehyde to a 250mL single-necked flask, and then add 0.36μL (1.0×10 -6 mol) with a mass fraction of 25% (CH 3 ) 4 Add 49.5 g (0.5 mol) of trimethylsilyl cyanide to NOH aqueous solution under room temperature and stirring state, the reaction is violent, TLC follows the reaction, after 20 minutes a small amount of sample is taken and sent to NMR, the calculated conversion rate is 98%.

Embodiment 3

[0026] Preparation of Cyclohexylformaldehyde Cyanohydrin Silicon Ether

[0027] Add 60mL (0.5mol) of freshly distilled cyclohexyl formaldehyde to a 250mL one-necked flask, then add 0.26g (1.0×10 -6 mol) n Bu 4 NOH solid, add 66.6mL (0.5mol) trimethylsilyl cyanide under stirring state at room temperature, the reaction is violent, after 10 minutes take a small amount and send it to NMR, the calculated conversion rate is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com