Method for preparing 6-gingerol and 8-gingerol from ginger and ultrafiltration device thereof

A technology of gingerol and ginger, applied in the preparation of 6-gingerol and 8-gingerol, the field of natural active product preparation, can solve the problems of long extraction process, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing 6-gingerol and 8-gingerol from ginger according to Example 1 of the present invention includes the following items in turn: raw material treatment, mixing and homogenization of ginger, removal of impurities to obtain the initial extract, and ultrafiltration to obtain the initial extract. It is prepared by the process steps of pure product and nanofiltration, as follows:

[0025] 1. Raw material processing: raw material processing is to take fresh ginger to remove the roots and petioles, wash it with water, and then pulverize it in a blender;

[0026] 2. Mixing and homogenizing: After the above-mentioned ginger powder is mixed with a mixed solvent of 3 times the volume of ethanol and water, homogenize in a high-speed homogenizer for 0.5 hours;

[0027] 3. Removing impurities: press-filter the mixed homogenate in an air pressure filter tank with an air pressure of 0.5MPA, and pass through a 300-mesh sieve.

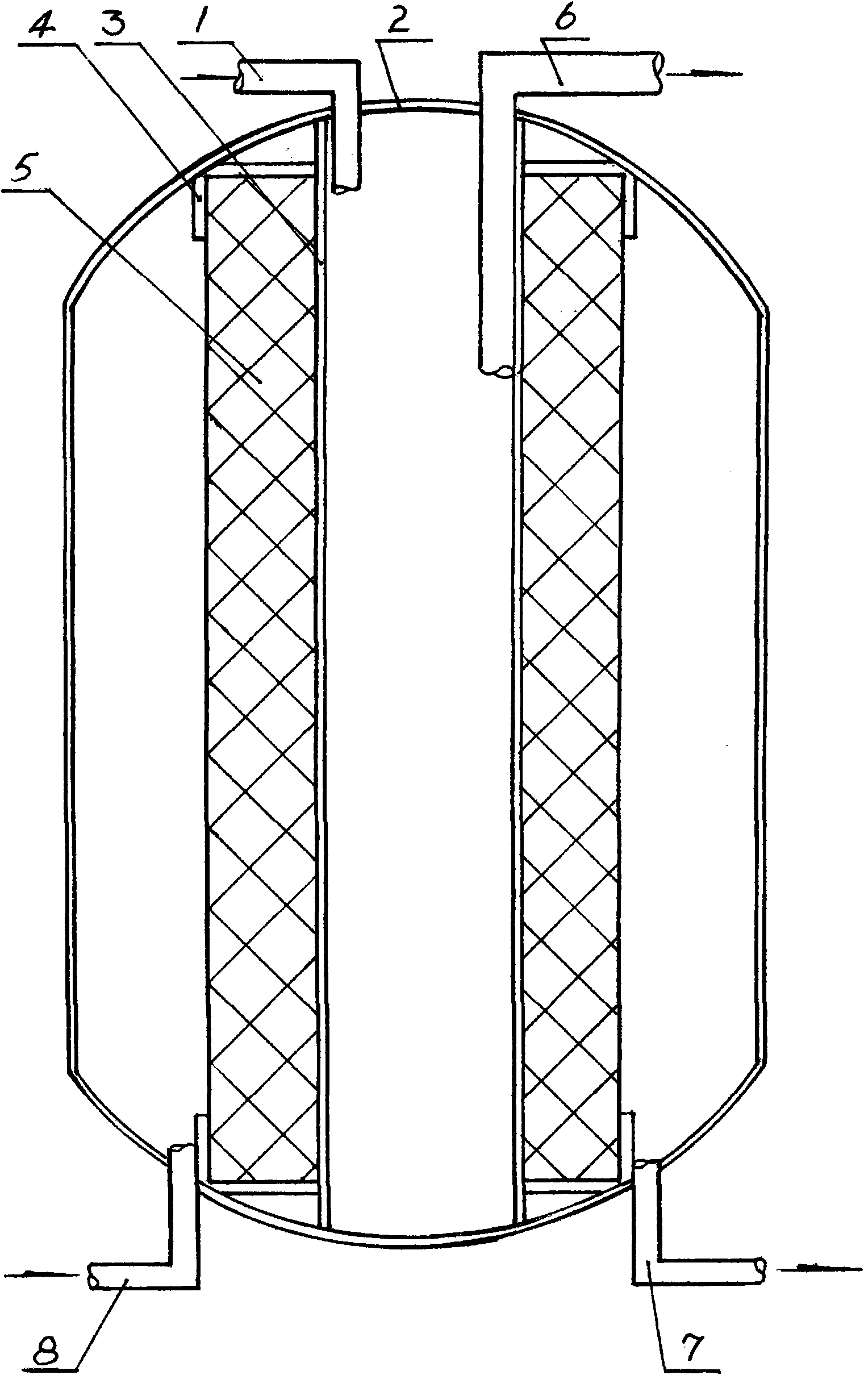

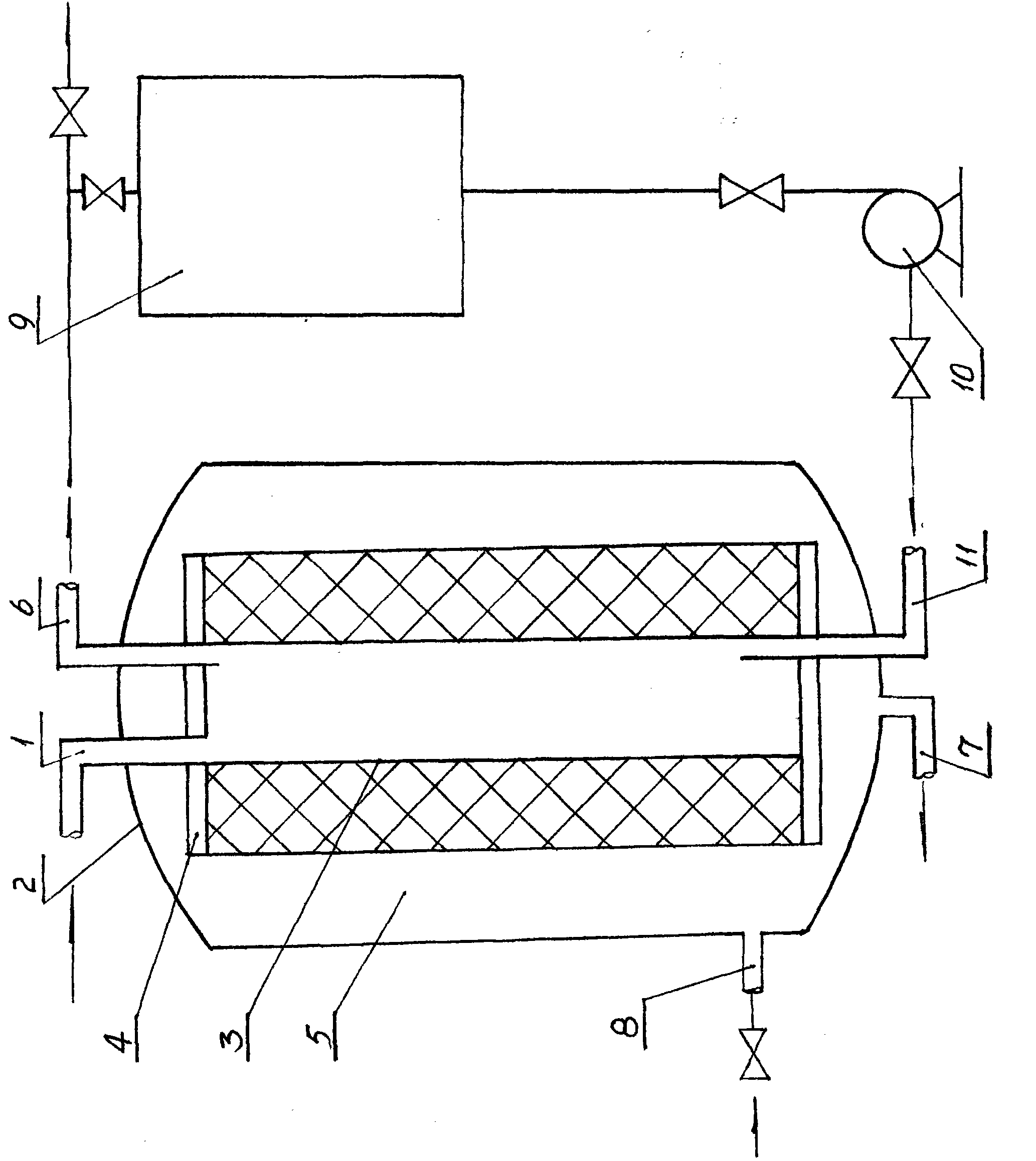

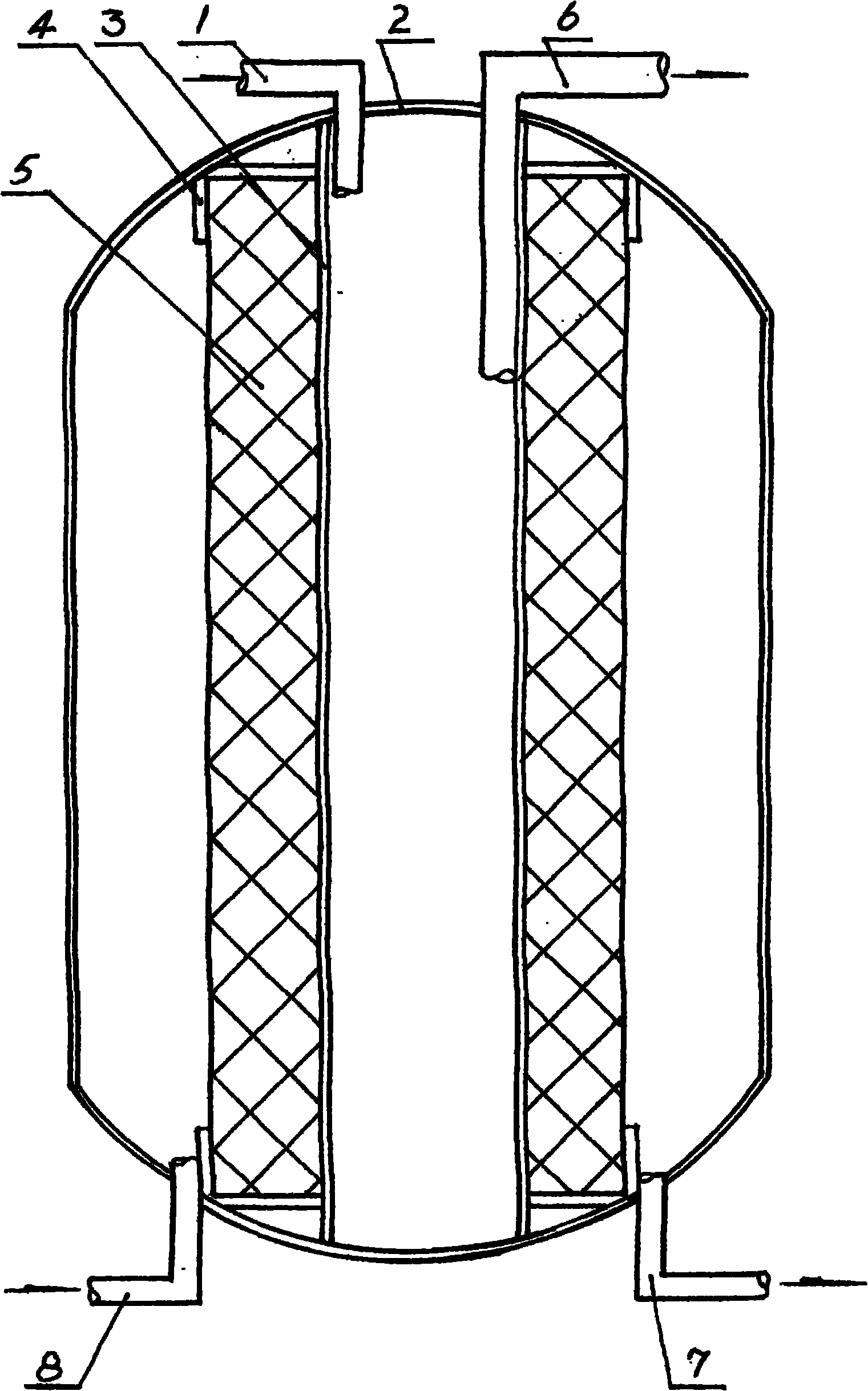

[0028] 4. Ultrafiltration: It is the fil...

Embodiment 2

[0034] A method for preparing 6-gingerol and 8-gingerol from ginger in Example 2 of the present invention comprises the following items in turn: raw material treatment, mixing and homogenization of ginger, removal of impurities to obtain the initial extract, ultrafiltration to obtain the initial It is prepared by the process steps of pure product and nanofiltration, as follows:

[0035] 1. Raw material processing: raw material processing is to take fresh ginger to remove the roots and petioles, wash it with water, and then pulverize it in a blender;

[0036] 2. Mixing and homogenizing: after mixing the above-mentioned ginger powder with 5 times the volume of ethanol, homogenizing in a high-speed homogenizer for 0.6 hours;

[0037] 3. Removing impurities: press-filter the mixed homogenate in an air pressure filter tank with an air pressure of 0.6MPA, and pass through a 400-mesh sieve.

[0038] 4. Ultrafiltration: It is the filtrate obtained by filtering the gingerol after pressu...

Embodiment 3

[0044] A method for preparing 6-gingerol and 8-gingerol from ginger according to Example 3 of the present invention comprises the following items in turn: raw material treatment, mixing and homogenization of ginger, removal of impurities to obtain the initial extract, and ultrafiltration to obtain the initial extract. It is prepared by the process steps of pure product and nanofiltration, as follows:

[0045] 1. Raw material processing: raw material processing is to take fresh ginger to remove the roots and petioles, wash it with water, and then pulverize it in a blender;

[0046] 2. Mixing and homogenizing: After mixing the above-mentioned ginger powder with 7 times the volume of ethanol, homogenize in a high-speed homogenizer for 1 hour;

[0047] 3. Removing impurities: press-filter the mixed homogenate in an air pressure filter tank with an air pressure of 0.7MPA, and pass through a 500-mesh sieve.

[0048] 4. Ultrafiltration: It is the filtrate obtained by filtering the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com