Preparation method of thermosensitive-film infrared detector

A technology of infrared detectors and heat-sensitive films, applied in the field of infrared detection, can solve problems such as uncontrollable resistance, large fluctuations, and affecting the quality of VOx, and achieve the effect of reducing the impact and preventing valence changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

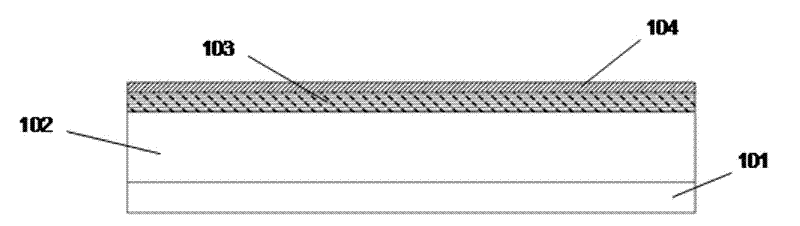

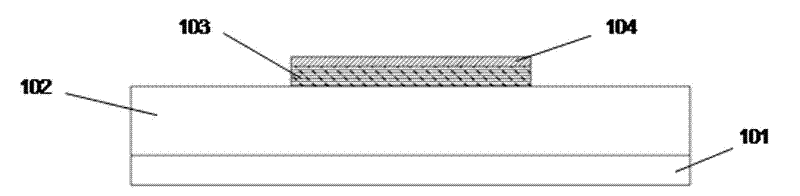

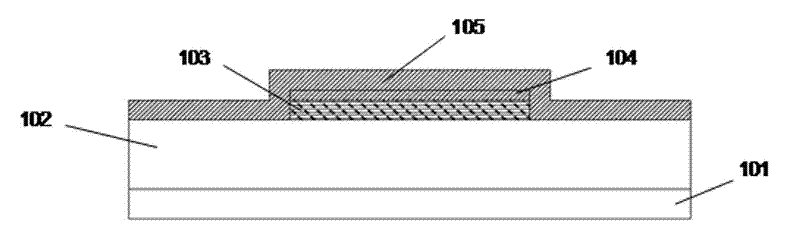

[0036] The method of the present invention has carried out large technological adjustment to traditional craft, promptly in VO x A thin layer of low-stress Si is first deposited on the film 3 N 4 film as VO x protective layer with a thickness of 350 ~650 . followed by photolithography and etching processes, VO x thin film and Si 3 N 4 The film is etched together to obtain VOx pattern, formed with Si 3 N 4 Protective film thermistor. After the etching is completed, dry and wet stripping processes are performed to completely remove the photoresist. Because of VO x a thin layer of Si 3 N 4 The thin film acts as a protective layer to isolate O plasma or H 2 The role of O molecules eliminates the impact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com