Multi-functional coating and preparation method thereof

A multifunctional, coating technology, applied in the field of coatings, can solve problems such as difficult construction, insufficient adhesion, and insufficient functions, and achieve the effect of good neutron absorption and radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

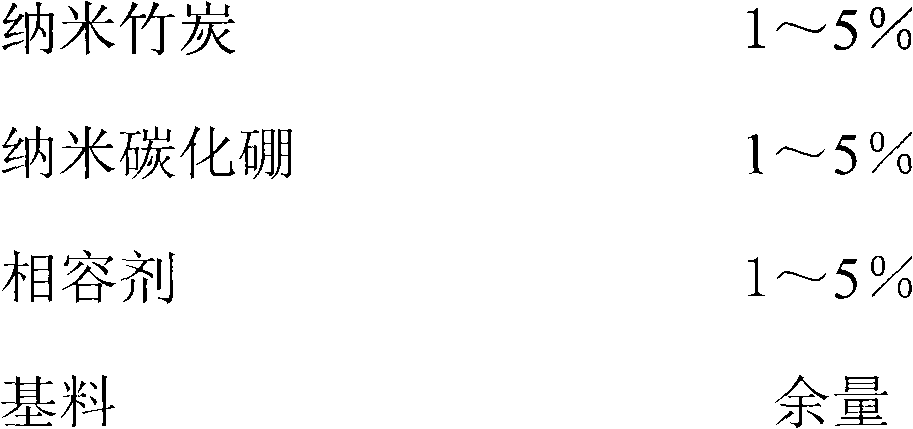

[0017] A kind of multifunctional paint, its raw material composition mass percent is,

[0018]

[0019] Described base material can be conventional paint,

[0020] The composition of base material is:

[0021]

[0022]

[0023] A preparation method of a multi-functional coating, dissolving nano-bamboo charcoal and nano-boron carbide in ethanol, a compatibilizer, and continuously stirring until completely dissolved to obtain a functional material; mixing the functional material with a base material to obtain the final product Versatile paint.

Embodiment 2

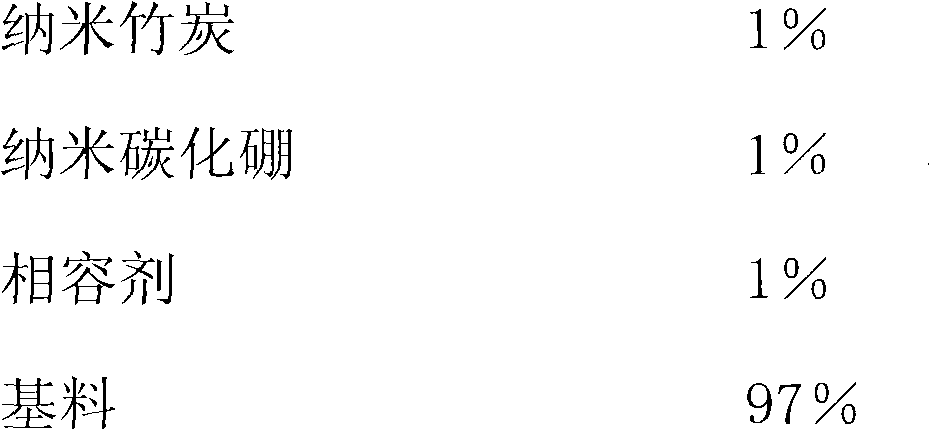

[0025] A kind of multifunctional paint, its raw material composition mass percent is,

[0026]

[0027] Described base material can be conventional paint,

[0028] The composition of base material is:

[0029]

[0030] A preparation method of a multi-functional coating, dissolving nano-bamboo charcoal and nano-boron carbide in ethanol, a compatibilizer, and continuously stirring until completely dissolved to obtain a functional material; mixing the functional material with a base material to obtain the final product Versatile paint.

Embodiment 3

[0032] A kind of multifunctional paint, its raw material composition mass percent is,

[0033]

[0034] Described base material can be conventional paint,

[0035] The raw material mass percent of base material is:

[0036] Novolac epoxy resin is 55%; filler is 44%; additive is 1%;

[0037] Described filler is selected from several in barium sulfate, silicon micropowder, mica powder;

[0038] The auxiliary agent is selected from polypropylene leveling agent powder auxiliary agent or fumed silica thixotropic agent.

[0039] A preparation method of a multifunctional coating, dissolving nano bamboo charcoal and nano boron carbide in compatibilizer ethanol, and stirring continuously until completely dissolved to obtain a functional material; mixing the functional material with a base material to obtain the final product Versatile paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com