Transparent treating agent for coating aqueous wooden ware and preparation method thereof

A technology of transparent treatment and woodware, applied in the direction of coating, etc., can solve the problems of high cleanliness requirements, high surface tension, poor wood wettability, etc., and achieve the effect of simple preparation process, fast drying speed, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

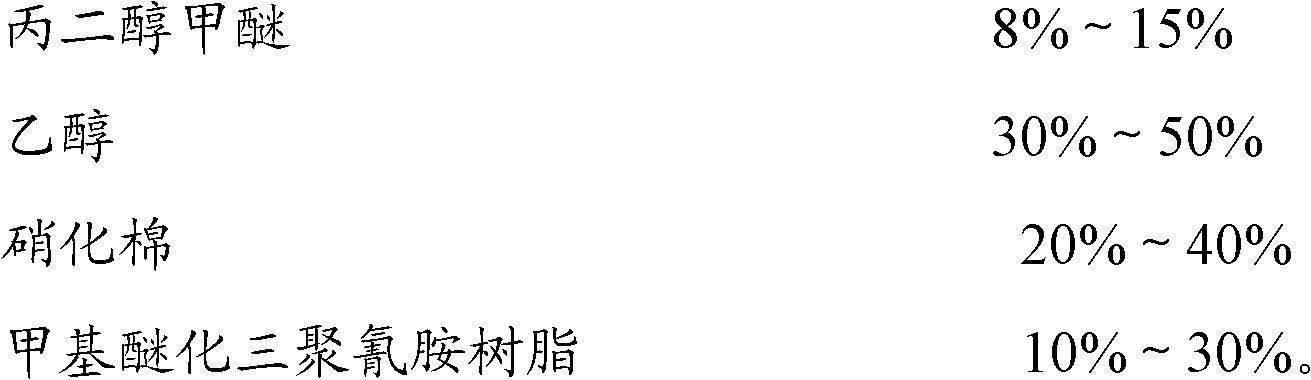

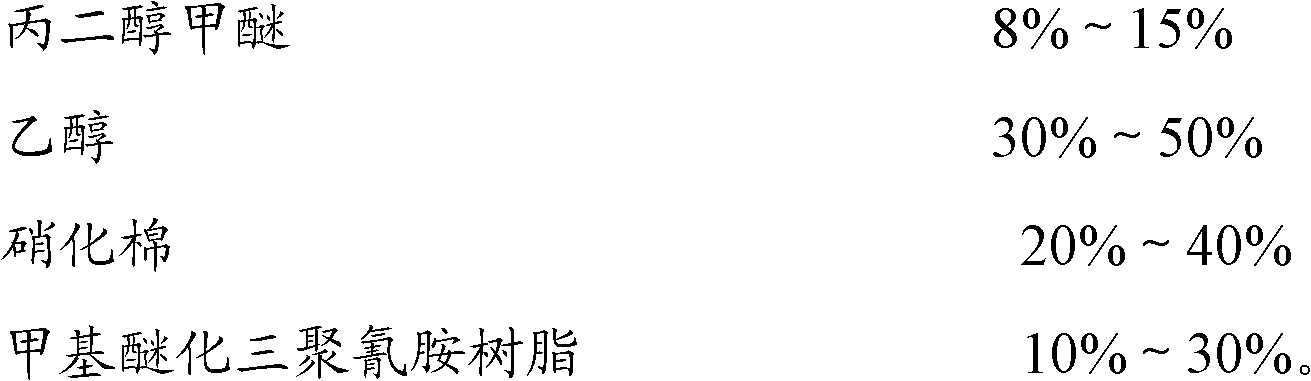

[0030] A water-based transparent treatment agent for wood coating, comprising the following substances calculated by weight percentage:

[0031] Propylene glycol methyl ether 15%, ethanol 50%, alcohol-soluble 1 / 2" nitrocellulose 25%, methyl etherified melamine resin (M-303 of Youda resin) 10%.

[0032] The diluent used to dilute the transparent treatment agent is composed of 1% ethylene glycol monobutyl ether and 99% ethanol calculated by weight percentage.

[0033] The method for preparing the transparent treatment agent comprises the following preparation steps:

[0034] Step A, transfer the amount of propylene glycol methyl ether and ethanol to the reactor respectively, and stir for 5 minutes at a rotating speed of 110 rpm;

[0035] Step B, adding the nitrocellulose during the stirring process in the reactor in step A, after adding the nitrocellulose, increase the stirring speed in the reactor to 900 rpm, and continue stirring for 30 minutes;

[0036] Step C, finally add ...

Embodiment 2

[0038] A water-based transparent treatment agent for wood coating, comprising the following substances calculated by weight percentage:

[0039] Propylene glycol methyl ether 8%, ethanol 32%), alcohol-soluble 1 / 4 "nitrocellulose 40%, methyl etherified melamine resin (CYMEL 303 of Cytec (CYTEC) company) 20%.

[0040] The diluent used to dilute the transparent treatment agent is composed of 3% ethylene glycol monobutyl ether and 97% ethanol calculated by weight percentage.

[0041] The method for preparing the transparent treatment agent comprises the following preparation steps:

[0042] Step A, transfer the amount of propylene glycol methyl ether and ethanol to the reactor respectively, and stir for 3 minutes under the condition that the rotating speed is 100 rpm;

[0043] Step B, adding the nitrocellulose during the stirring process in the reactor in step A, after adding the nitrocellulose, increase the stirring speed in the reactor to 800 rpm, and continue stirring for 20 m...

Embodiment 3

[0046] A water-based transparent treatment agent for wood coating, comprising the following substances calculated by weight percentage:

[0047] Propylene glycol methyl ether 10%, ethanol 40%, alcohol-soluble 1 / 8″ nitrocellulose 30%, methyl etherified melamine resin (CYMEL 350 of CYTEC Company) 20%.

[0048]The diluent used to dilute the transparent treatment agent is composed of 5% ethylene glycol monobutyl ether and 95% ethanol calculated by weight percentage.

[0049] The method for preparing the transparent treatment agent comprises the following preparation steps:

[0050] Step A, transfer the amount of propylene glycol methyl ether and ethanol to the reactor respectively, and stir for 3 minutes under the condition that the rotating speed is 100 rpm;

[0051] Step B, adding the nitrocellulose during the stirring process in the reactor in step A, after adding the nitrocellulose, increase the stirring speed in the reactor to 800 rpm, and continue stirring for 20 minutes; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com