Nano composite intumescent flame retardant and preparation method thereof

An intumescent flame retardant and nano-composite technology, which is applied in the field of flame retardants to improve mechanical properties, reduce production costs, and facilitate industrial implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

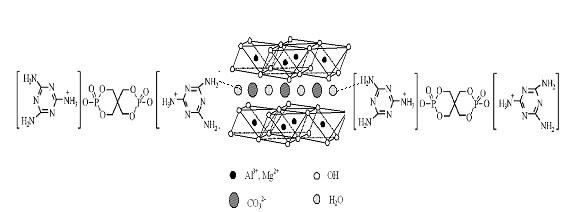

Method used

Image

Examples

Embodiment 2

[0045] Example 2: Studying the Effect of Ultrasonic Conditions on the Particle Size of Nanocomposite Intumescent Flame Retardants

[0046] The preparation method is the same as in Example 1, and the reaction system without ultrasound is used as a parallel reference, and the comparison results are reflected by the XRD pattern, and the results are shown in Figure 5 (a), Figure 5 (b); according to Figure 5 (a), Figure 5 ( b) Calculate the LDH particle size with the Scherrer formula, and the calculation results are shown in Table 1 (a) and Table 1 (b):

[0047] Table 1(a)

[0048]

[0049] Table 1(b)

[0050]

Embodiment 3

[0051] Example 3: Studying the Effect of Different Solvents on the Particle Size of Nanocomposite Intumescent Flame Retardants

[0052] The preparation method is the same as in Example 1, and different solvents are used as the reaction solvent in step (1), and the reaction is carried out under ultrasonic conditions for 1 h. After the reaction, the ultrasonic is turned off, and the crystallization is carried out at 60° C. for 4 h. The results are shown in Figure 6(a) and Figure 6(b) respectively. According to Fig. 6 (a), Fig. 6 (b) calculate LDH particle size with Scherrer formula, calculation result table 2 (a), table 2 (b) as shown:

[0053] Table 2(a)

[0054]

[0055] Table 2(b)

[0056]

Embodiment 4

[0057] Example 4: Studying the effect of different reaction temperatures on the particle size of nanocomposite intumescent flame retardants

[0058] The preparation method was the same as that in Example 1, and different temperatures were used as the temperature for the ultrasonic reaction, and the reaction was kept under ultrasonic conditions for 1 hour. After the reaction was completed, the ultrasonic was turned off, and the crystallization was carried out at 60° C. for 4 hours. The results are shown in Figure 7(a), Figure 7(b), and Figure 7(c). According to Fig. 7 (a), Fig. 7 (b), Fig. 7 (c) use Scherrer formula to calculate LDH particle size, calculation result is shown in table 3 (a), table 3 (b), table 3 (c):

[0059] Table 3(a)

[0060]

[0061] Table 3(b)

[0062]

[0063] Table 3(c)

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com