Ceramic dielectric sensor and preparation method thereof used for detecting relative volume concentration of methanol gasoline

A technology of ceramic medium and methanol gasoline, which is applied in the field of sensors, can solve the problems of unsuitable on-line detection, complicated detection methods, and low quality of methanol, and achieve the effects of low energy consumption and preparation cost, fast response-recovery time, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

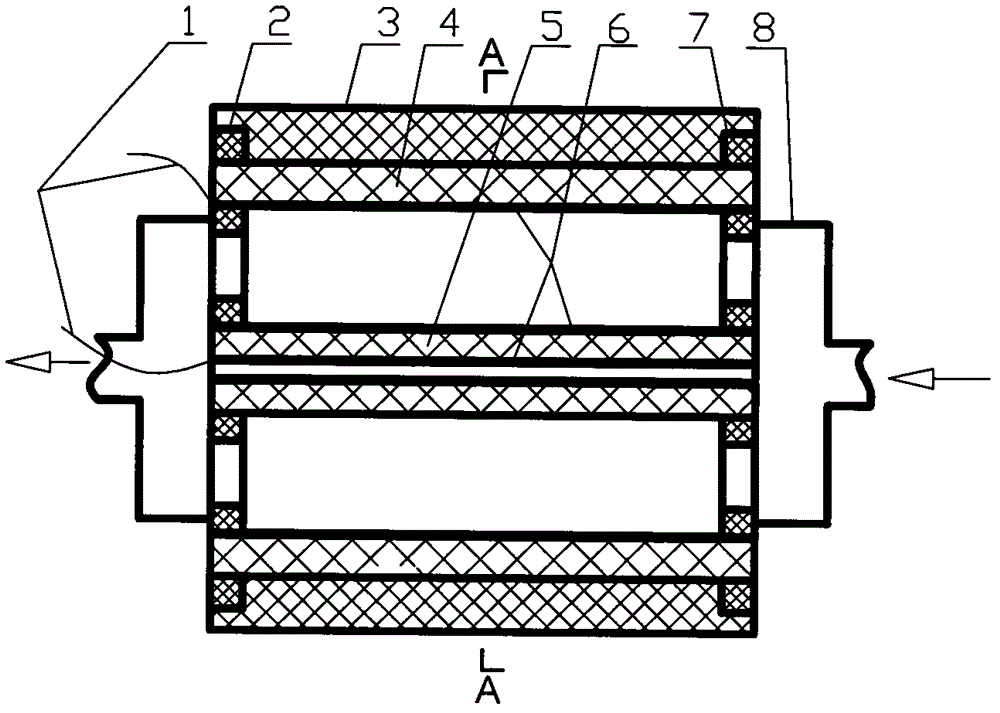

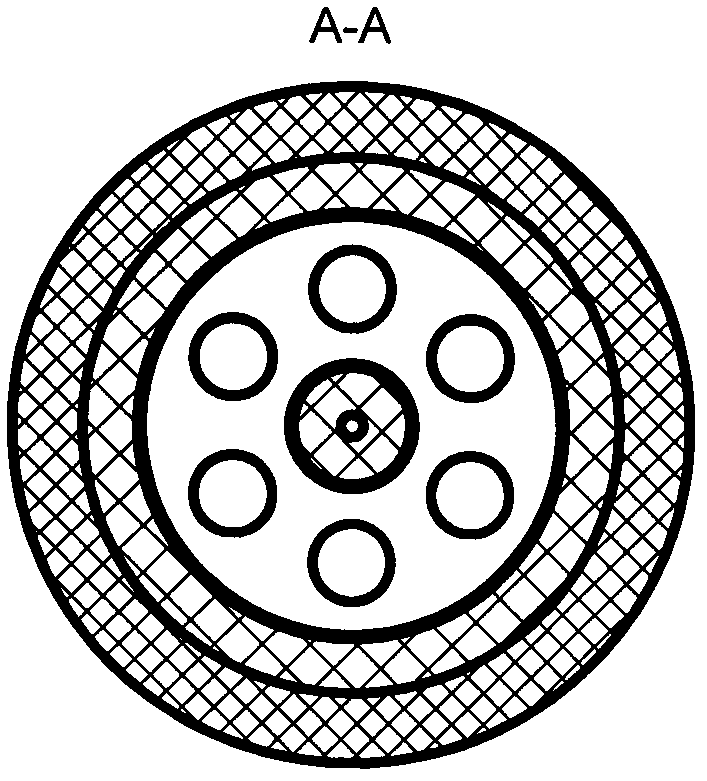

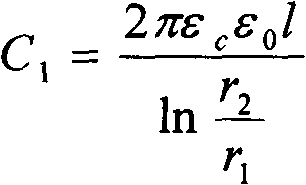

Image

Examples

Embodiment 1

[0025] 1) Weigh 100 grams of titanium dioxide, add it to a ball mill, wet grind it with water for 20 hours, dry it completely at a temperature of 100-120°C, pass through a 200-mesh sieve, and then calcinate it in an air sintering furnace at 1000°C for 2 hours according to a conventional sintering system , to synthesize TiO with rutile structure 2 Weigh 80 grams of titanium dioxide and 168 grams of magnesium carbonate, add them to a ball mill, use water as the grinding medium for wet grinding for 10 hours, dry them completely at a temperature of 100-120°C, and pass through a 200-mesh sieve. Afterwards, it was calcined at 1150 °C for 2 h in an air sintering furnace according to the conventional sintering system to synthesize Mg 2 TiO 4 Material.

[0026] 2) According to 0.8TiO 2 -0.2Mg 2 TiO 4 The material weighs the TiO of the rutile synthesized in the front (1). 2 Material 80g, Mg 2 TiO 4 Mix 20 grams of raw materials to form a composite powder, put into a ball mill, u...

Embodiment 2

[0031] The preparation process steps are the same as in Example 1, except that in step 1), the sintering temperature is 1150° C. for 2 h in an air sintering furnace to synthesize TiO with a rutile structure. 2 ; Calcined at 1200°C for 2 hours in an air sintering furnace to synthesize Mg 2 TiO 4 Material; take the TiO of rutile structure in step 2) 2 Material 50g, take Mg 2 TiO 4 50 grams of materials, mixed to form a composite powder; after the molded ceramic green body with the same size as in Example 1 is subjected to the debinding process, the sintering temperature is 1280 ° C under air conditions and sintered to form a ceramic medium; in step 5) In Table 1, the test results of different concentrations of methanol gasoline liquid capacitors are shown in Table 1.

Embodiment 3

[0033] The preparation process steps are the same as in Example 1, except that in step 1), the sintering temperature is 1200 ° C for 2 h in an air sintering furnace to synthesize TiO with a rutile structure. 2 ; Calcined at 1250°C for 2 hours in an air sintering furnace to synthesize Mg2 TiO 4 Material; take the TiO of rutile structure in step 2) 2 Material 50g, take Mg 2 TiO 4 80 grams of materials, mixed to form a composite powder; after the molded ceramic green body with the same size as in Example 1 is subjected to the debinding process, the sintering temperature is 1380 ° C under air conditions and sintered to form a ceramic medium; in step 5) The test results of different concentrations of methanol gasoline liquid capacitors are shown in Table 1.

[0034] Table 1 has listed the result that adopts ceramic dielectric sensor of the present invention to test different volume concentration methanol gasoline fuels as follows:

[0035]

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com