Preparation method of super capacitor based on one-dimensional metal-carbon nano tube coaxial heterojunction

A coaxial heterojunction, carbon nanotube technology, applied in the fields of nanotechnology and energy storage, can solve the problems of poor orientation of carbon nanotubes, limited practical application, high filling rate, etc., to reduce contact resistance and shorten charging and discharging time. , reduce the effect of bad contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

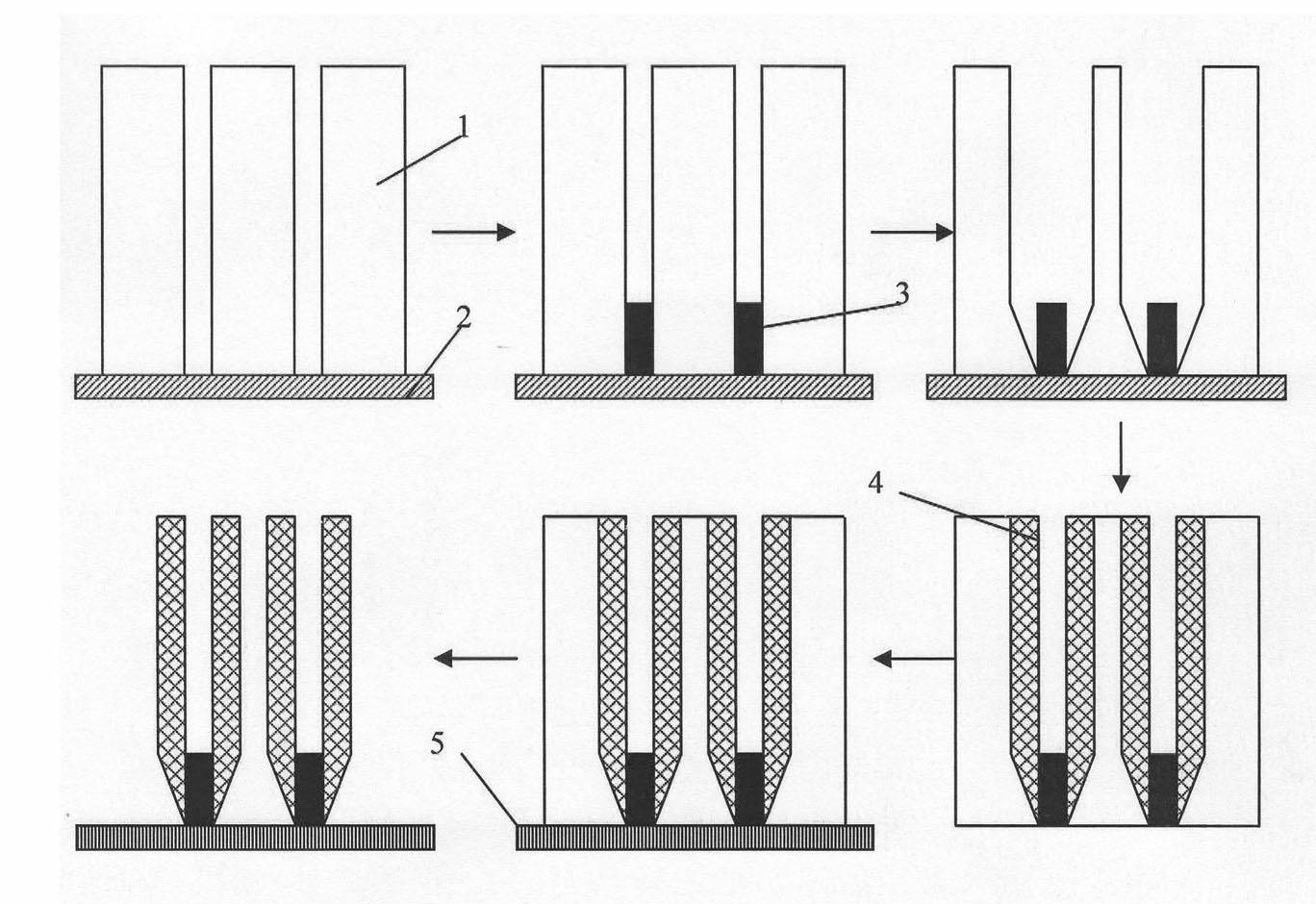

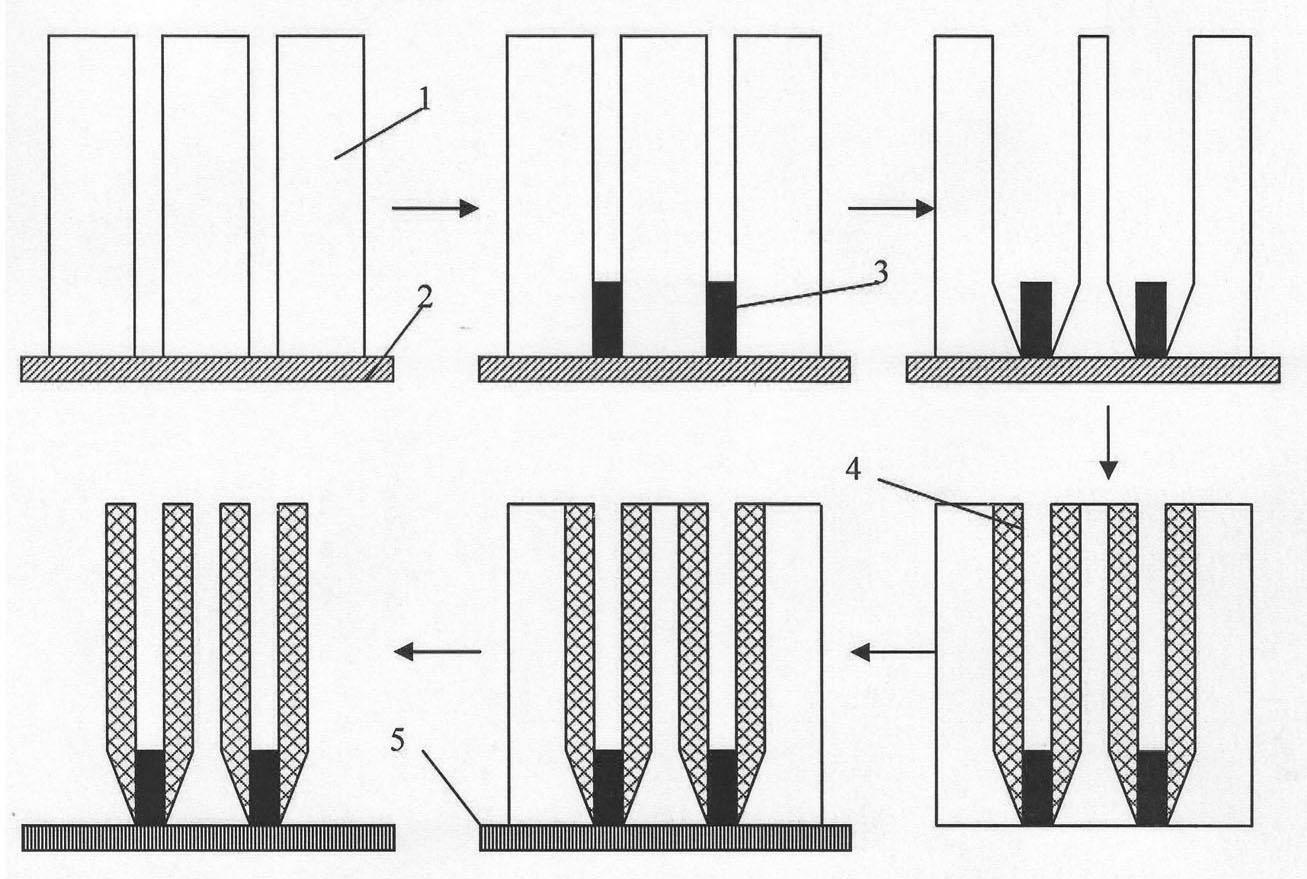

[0032] like figure 1 As shown, a layer of silver film 2 is plated on one side of the through-hole anodized aluminum template 1 using a magnetron sputtering coating machine, as an electrode for electrochemical deposition. Silver film 2 was chosen because of the greater conductivity of silver.

[0033] The above-mentioned anodized aluminum oxide template 1 is used as the cathode, and the silver single substance sheet is used as the anode, and silver nanowires 3 are deposited in the pores of the anodized aluminum oxide template 1 by electrochemical deposition. The composition of the electroplating solution is: 15g L -1 C 6 h 8 o7 ·H 2 O, 4g L -1 AgNO 3 , 20g·L -1 MgSO 4 , The deposition voltage is 0. 4V, and the deposition time is 15min. After removal, rinse with deionized water and dry.

[0034] Use a phosphoric acid solution with a temperature of 50°C and a volume ratio of 5% to expand the pores of the anodized aluminum template 1 that has been deposited with silver ...

Embodiment 2

[0040] like figure 1 As shown, a layer of silver film 2 is plated on one side of the through-hole anodized aluminum template 1 using a magnetron sputtering coating machine, as an electrode for electrochemical deposition. Silver film 2 was chosen because of the greater conductivity of silver.

[0041] The above-mentioned anodized aluminum oxide template 1 is used as the cathode, and the silver single substance sheet is used as the anode, and silver nanowires 3 are deposited in the pores of the anodized aluminum oxide template 1 by electrochemical deposition. The composition of the electroplating solution is: 15g L -1 C 6 h 8 o 7 ·H 2 O, 4g L -1 AgNO 3 , 20g·L -1 MgSO 4 , The deposition voltage was 0.3V, and the deposition time was 30min. After removal, rinse with deionized water and dry.

[0042] Use a phosphoric acid solution with a temperature of 50°C and a volume ratio of 10% to expand the pores of the anodized aluminum template 1 that has been deposited with sil...

Embodiment 3

[0048] like figure 1 As shown, a layer of silver film 2 is plated on one side of the through-hole anodized aluminum template 1 using a magnetron sputtering coating machine, as an electrode for electrochemical deposition. Silver film 2 was chosen because of the greater conductivity of silver.

[0049] The above-mentioned anodized aluminum oxide template 1 is used as the cathode, and the silver single substance sheet is used as the anode, and silver nanowires 3 are deposited in the pores of the anodized aluminum oxide template 1 by electrochemical deposition. The composition of the electroplating solution is: 15g L -1 C 6 h 8 o 7 ·H 2 O, 4g L -1 AgNO 3 , 20g·L -1 MgSO 4 , the deposition voltage is 0.6V, and the deposition time is 15min. After removal, rinse with deionized water and dry.

[0050] Use a phosphoric acid solution with a temperature of 50°C and a volume ratio of 5% to expand the pores of the anodized aluminum template 1 that has been deposited with silver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com