High-power semiconductor chip laser array

A thin-film laser and semiconductor technology, used in semiconductor lasers, semiconductor laser excitation devices, lasers, etc., can solve the problems of single laser wavelength range, large laser volume, and low service life, and achieve favorable heat dissipation, high beam quality, and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

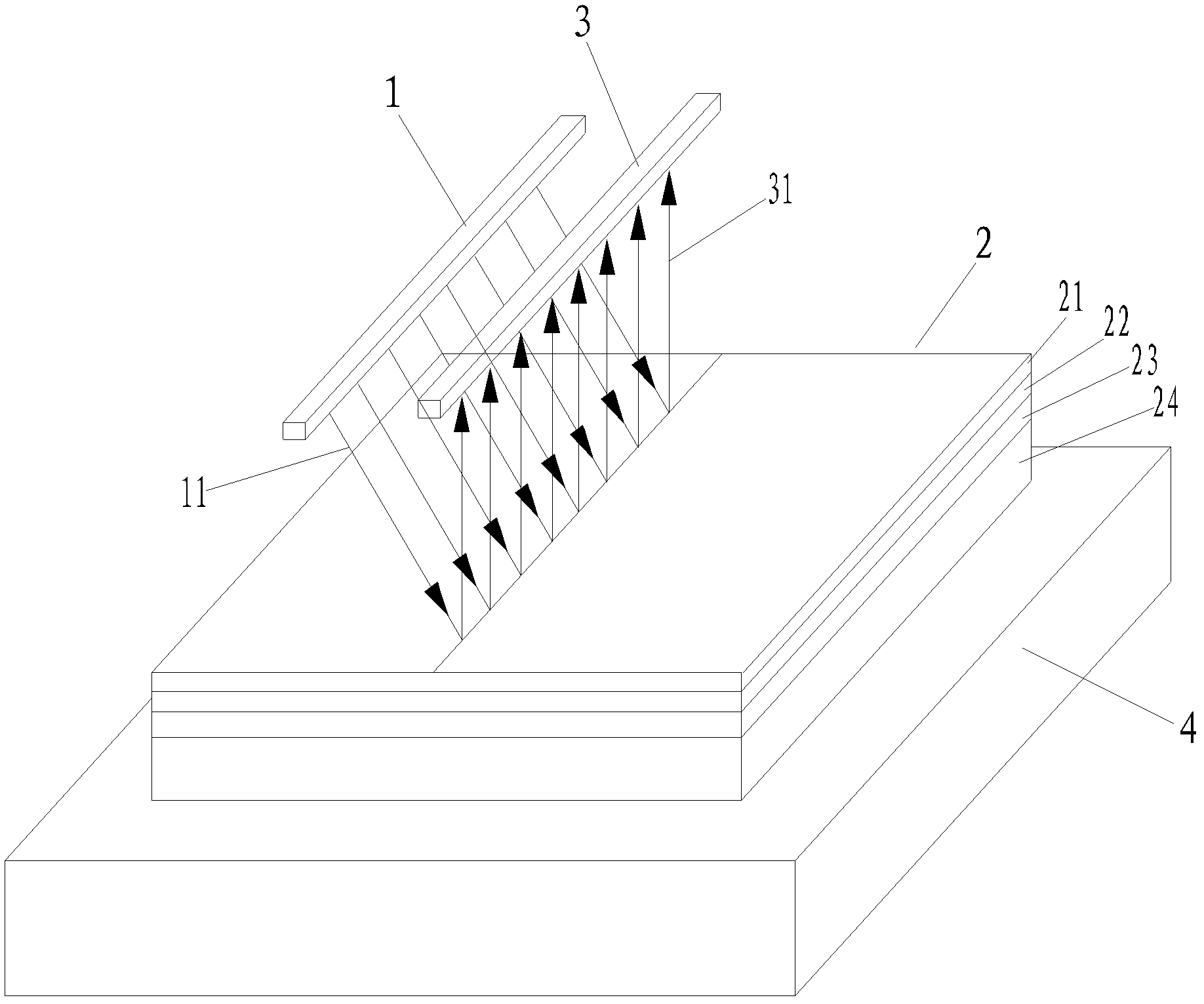

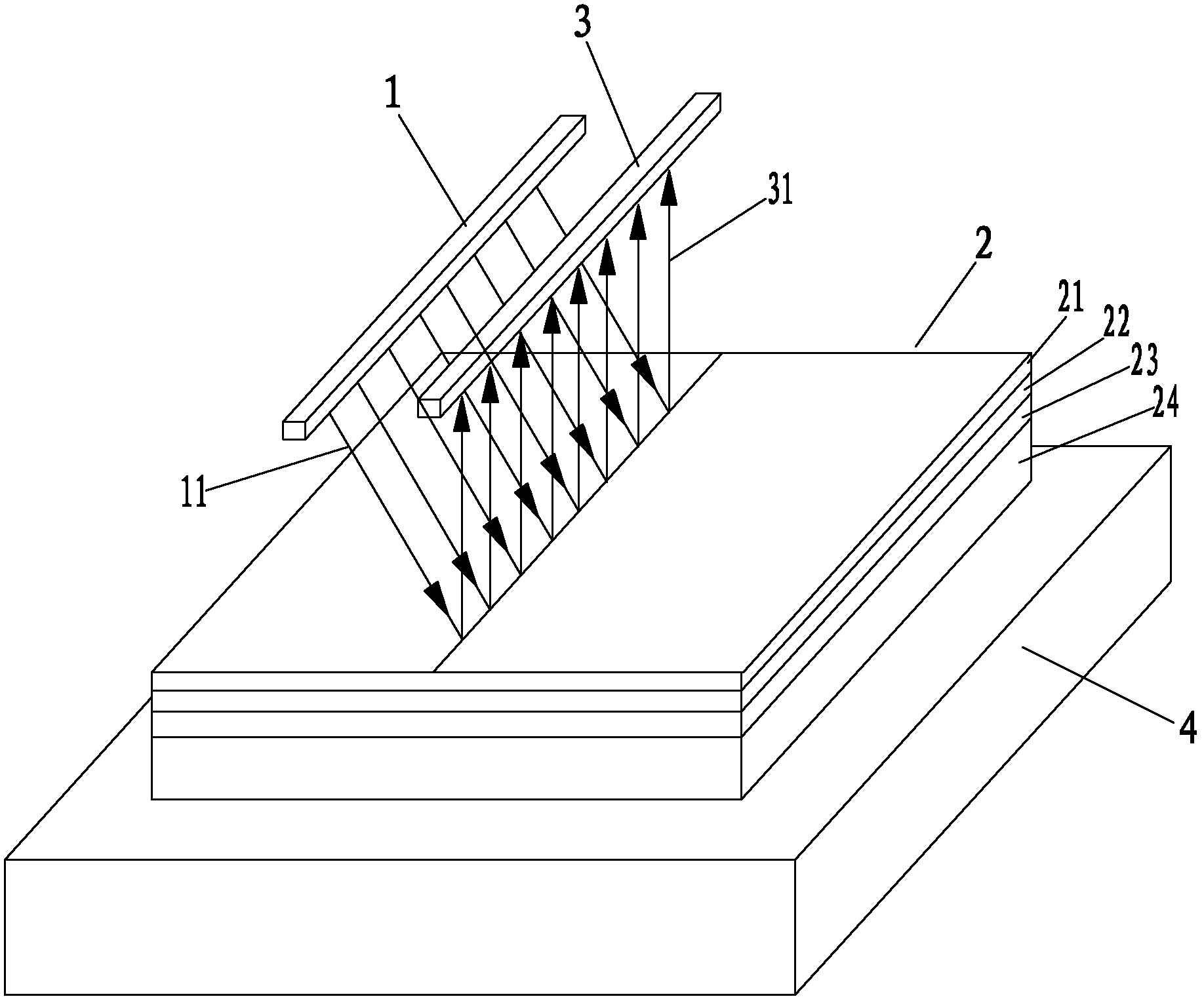

[0015] figure 1 It is a schematic diagram of the structural principle of the present invention, as shown in the figure: the high-power semiconductor thin-disk laser array of this embodiment includes a pump light source system 1, a semiconductor gain thin slice 2 and a microcavity mirror array 3, a semiconductor gain thin slice 2 and a microcavity The mirror array 3 forms a resonant cavity, and the pump light source system 1 includes a semiconductor laser array and a shaping component. The semiconductor laser array is shaped by the shaping component to form a pumping beam array 11, and the pumping beam array 11 is incident on the semiconductor gain The sheet 2, the microcavity mirror array 3 is used to output the laser array 31.

[0016] In this embodiment, the semiconductor gain sheet 2 includes a heat dissipation window layer 21, a multi-quantum well active layer 22 and a distributed Bragg reflection layer 23 from top to bottom; The stacking method of capillary bonding techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com