Method for preparing powdery cheese and obtained powdery cheese

A cheese and powder technology, applied in the field of preparation of powder cheese, can solve the problems of low unsaturated fatty acid, easy sticking of natural cheese, unfavorable cleaning of equipment, etc., and achieves low moisture content, easy preparation, and reduced risk of microbial deterioration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Ingredients according to 1 ton of production:

[0042]

[0043]

[0044] Preparation:

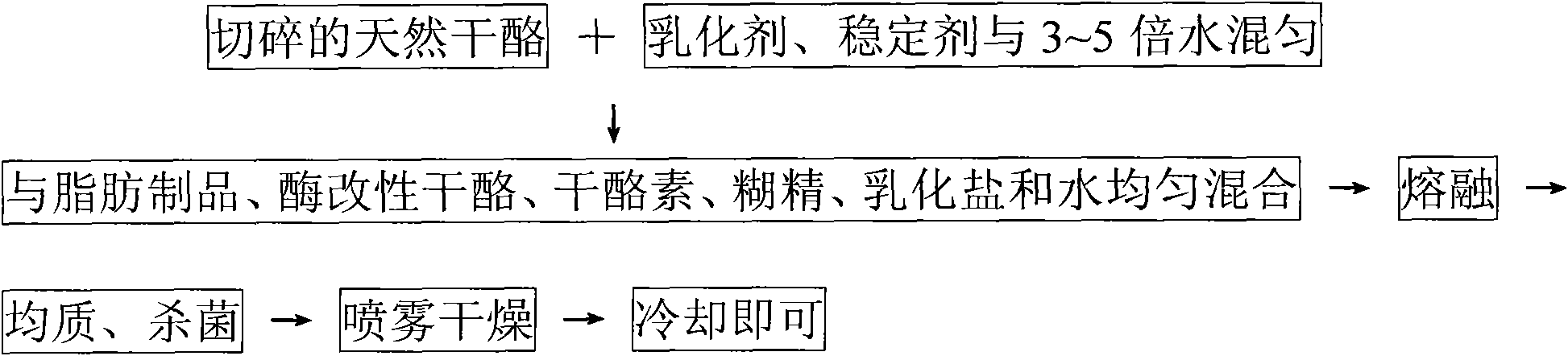

[0045](1) Uniformly mix shredded natural cheese with fat products, enzyme-modified cheese, casein, dextrin, emulsifying salt, emulsifier, stabilizer and water according to the formula in the above table; wherein, the emulsifier and stabilizer Before the agent is mixed with the raw material natural cheese, it is evenly mixed with water that is 3 times the total mass of the emulsifier and stabilizer, and then evenly mixed with other substances;

[0046] (2) Melting: batch-type melting process, the melting pot is a high-speed cutting knife, the rotating speed is 1350rpm, the heating temperature is 92.5°C, and the melting time is 10min;

[0047] (3) Homogenization: Homogenization pressure is 15Mpa;

[0048] (4) Sterilization: pasteurization at 85°C for 10 minutes;

[0049] (5) Spray drying: the feed temperature is 82.5°C, the inlet air temperature is 150°C, and the outlet air te...

Embodiment 2

[0054] Ingredients according to 1 ton of production:

[0055]

[0056]

[0057] Preparation:

[0058] (1) Uniformly mix shredded natural cheese with fat products, enzyme-modified cheese, casein, dextrin, emulsifying salt, emulsifier, stabilizer and water according to the formula in the above table; wherein, the emulsifier and stabilizer Before the agent is mixed with the raw material natural cheese, it is uniformly mixed with water that is 5 times the total mass of the emulsifier and stabilizer, and then evenly mixed with other substances;

[0059] (2) Melting: batch-type melting process, the melting pot is a high-speed cutting knife, the rotating speed is 1000rpm, the heating temperature is 65°C, and the melting time is 30min;

[0060] (3) Homogenization: Homogenization pressure is 20Mpa;

[0061] (4) Sterilization: pasteurization at 98°C for 5 minutes;

[0062] (5) Spray drying: the feed temperature is 70°C, the inlet air temperature is 170°C, and the outlet air tem...

Embodiment 3

[0067] Ingredients according to 1 ton of production:

[0068]

[0069]

[0070] Preparation:

[0071] (1) Uniformly mix shredded natural cheese with fat products, enzyme-modified cheese, casein, dextrin, emulsifying salt, emulsifier, stabilizer and water according to the formula in the above table; wherein, the emulsifier and stabilizer Before the agent is mixed with the raw material natural cheese, it is evenly mixed with water that is 4 times the total mass of the emulsifier and stabilizer, and then evenly mixed with other substances;

[0072] (2) Melting: batch-type melting process, the melting pot is a double auger, the rotating speed is 150rpm, the heating temperature is 120°C, and the melting time is 5min;

[0073] (3) Homogenization: Homogenization pressure is 30Mpa;

[0074] (4) Sterilization: pasteurization at 91.5°C for 7.5 minutes;

[0075] (5) Spray drying: the feed temperature is 95°C, the inlet air temperature is 190°C, and the outlet air temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com