Fresh-keeping bacteriostatic lyophobic porous film for juicy food and preparation technology thereof

A technology of porous film and preparation process, applied in the fields of food preservation, food science, application, etc., can solve the problems of quality variation, waste, source out of control, etc., and achieve the effect of blocking bacterial invasion and growth, prolonging shelf life, and preventing qualitative change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

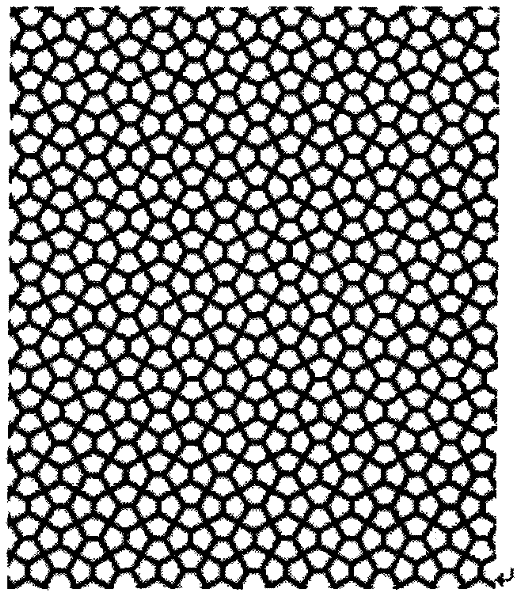

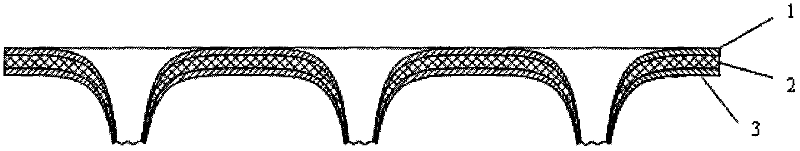

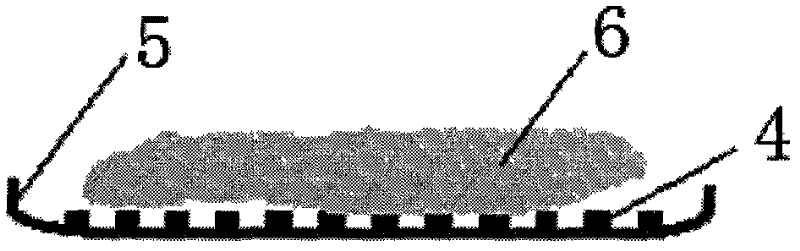

[0018] Example 1, a fresh-keeping, antibacterial, and liquid-repellent porous film containing juicy food materials is a single-layer microstructure, including a contact layer, an intermediate layer, and a back layer; its preparation process is to configure raw materials, wherein PE0-100%, PP100-0%, Antibacterial agent 0-10%, others (hydrophilic agent, colorant, etc.) 0-10%, pore forming method one-step or two-step vacuum pore forming and mechanical pore forming, vacuum pore forming is a plastic raw material technology for film formation, The hole is formed by negative pressure suction. The one-step method is to complete the film formation and hole formation online at one time. The two-step method is to complete the film formation and hole formation on two equipments respectively. Die extrusion, shearing and piercing to form holes. The antibacterial agent is a polymer antibacterial agent containing silver ions, copper ion antibacterial agents and antibacterial groups. The basis...

Embodiment 2

[0019] Example 2, a fresh-keeping antibacterial and liquid-repellent porous film containing juicy foods has two layers of microstructure, and each layer unit includes a contact layer, an intermediate layer, and a back layer; its preparation process is to configure raw materials, wherein PE0-100%, PP100- 0%, bacteriostatic agent 0-10%, other (hydrophilic agent, colorant, etc.) 0-10%, pore forming method one-step or two-step vacuum pore forming and mechanical pore forming, vacuum pore forming is a plastic raw material technology Film formation, and hole formation by negative pressure suction, one-step method is film formation, hole formation is completed online at one time, two-step method is film formation, hole formation is completed on two devices respectively, mechanical drilling, that is, under the action of mechanical force Next, it is extruded, sheared and penetrated by a knife die to form holes. The antibacterial agent is a polymer antibacterial agent containing silver i...

Embodiment 3

[0020] Example 3, a fresh-keeping antibacterial and liquid-repellent porous film containing juicy foods has three layers of microstructure, and each layer unit includes a contact layer, an intermediate layer, and a back layer; its preparation process is to configure raw materials, wherein PE0-100%, PP100- 0%, bacteriostatic agent 0-10%, other (hydrophilic agent, colorant, etc.) 0-10%, pore forming method one-step or two-step vacuum pore forming and mechanical pore forming, vacuum pore forming is a plastic raw material technology Film formation, and hole formation by negative pressure suction, one-step method is film formation, hole formation is completed online at one time, two-step method is film formation, hole formation is completed on two devices respectively, mechanical drilling, that is, under the action of mechanical force Next, it is extruded, sheared and penetrated by a knife die to form holes. The antibacterial agent is a polymer antibacterial agent containing silver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com