Mosapride citrate sustained-release tablet

A technology of mosapride citrate and sustained-release tablets, which is applied in the direction of medical preparations of non-active ingredients, digestive system, organic active ingredients, etc., can solve the problem of increased repetitive research work, poor compliance, and differences in release Larger issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Prescription:

[0026] Mosapride citrate

15g

HPMC K4M

30g

HPMC K15M

15g

40g

80% ethanol solution

Appropriate amount

2g

Opadry

2g

A total of 1000 pieces were made

[0027] 2. Process steps:

[0028] Take mosapride citrate, pulverize it and pass through a 100-mesh sieve, mix it with HPMCK4M, HPMCK15M and lactose, etc., moisten it with 80% ethanol, granulate it, dry it at 50°C, granulate it, add magnesium stearate, Mix evenly, press tablets, and coat with Opadry.

[0029] Release measurement method:

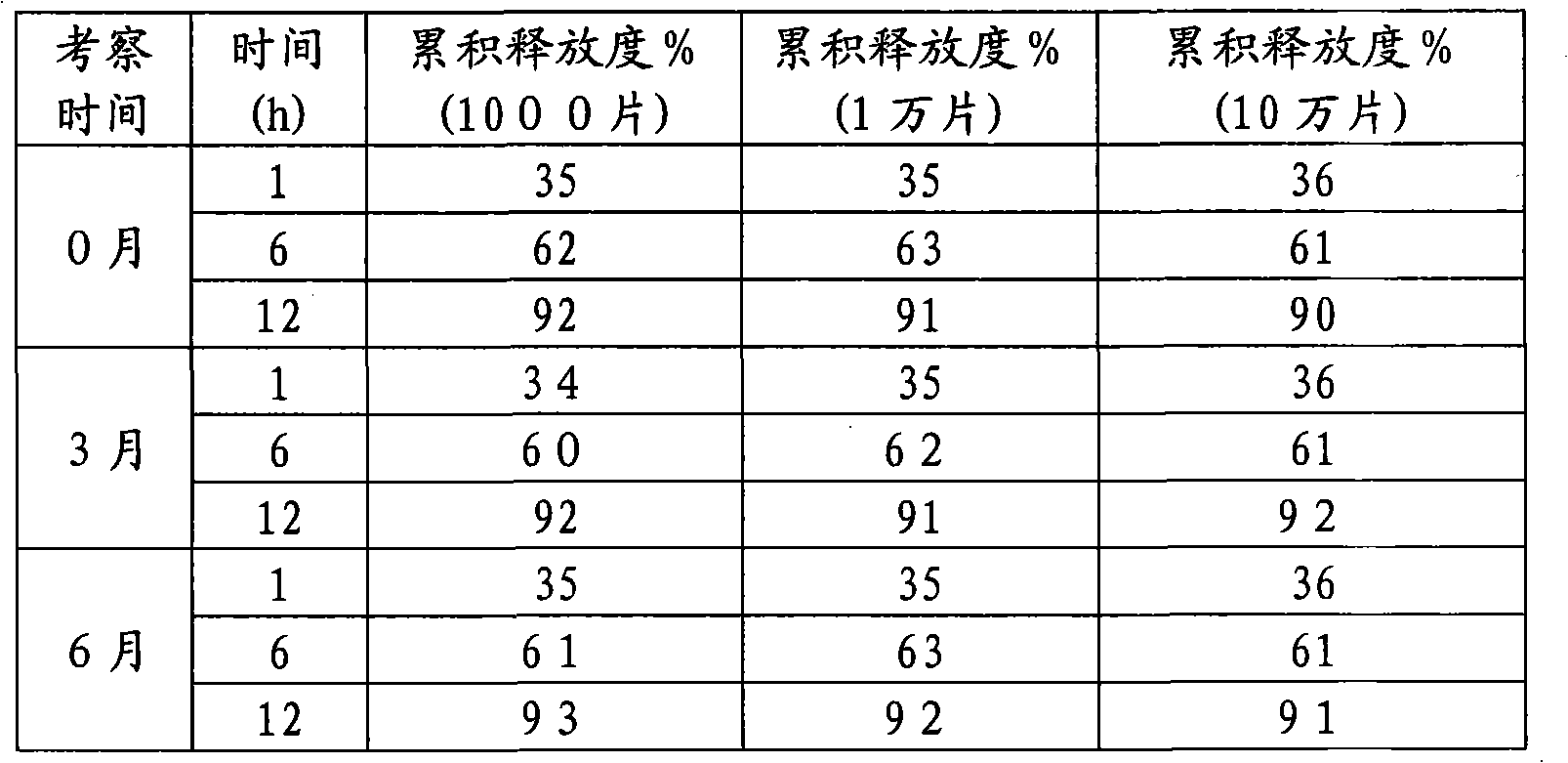

[0030] Get this product, according to dissolution assay (Chinese Pharmacopoeia version in 2005 two appendices XC second method), with 0.1mol / L hydrochloric acid solution 900ml as dissolution medium, rotating speed is 75 revolutions per minute, operate according to law, through 1, 6, After 12 hours, 10ml of the solution was taken, filtere...

Embodiment 2

[0039] 1. Prescription:

[0040] Mosapride citrate

15g

HPMC K4M

25g

HPMC K15M

10g

40g

70% ethanol solution

Appropriate amount

1g

Micropowder silica gel

1g

Opadry

1g

A total of 1000 pieces were made

[0041] 2. Process steps:

[0042] Take mosapride citrate, crush it and pass through a 100-mesh sieve, mix it evenly with HPMCK4M, HPMCK15M and microcrystalline cellulose, moisten it with 70% ethanol, granulate it, dry it at 50°C, granulate it, and add stearin Magnesium acid, micropowder silica gel, mixed evenly, pressed into tablets, coated with Opadry. The release measurement results are as follows:

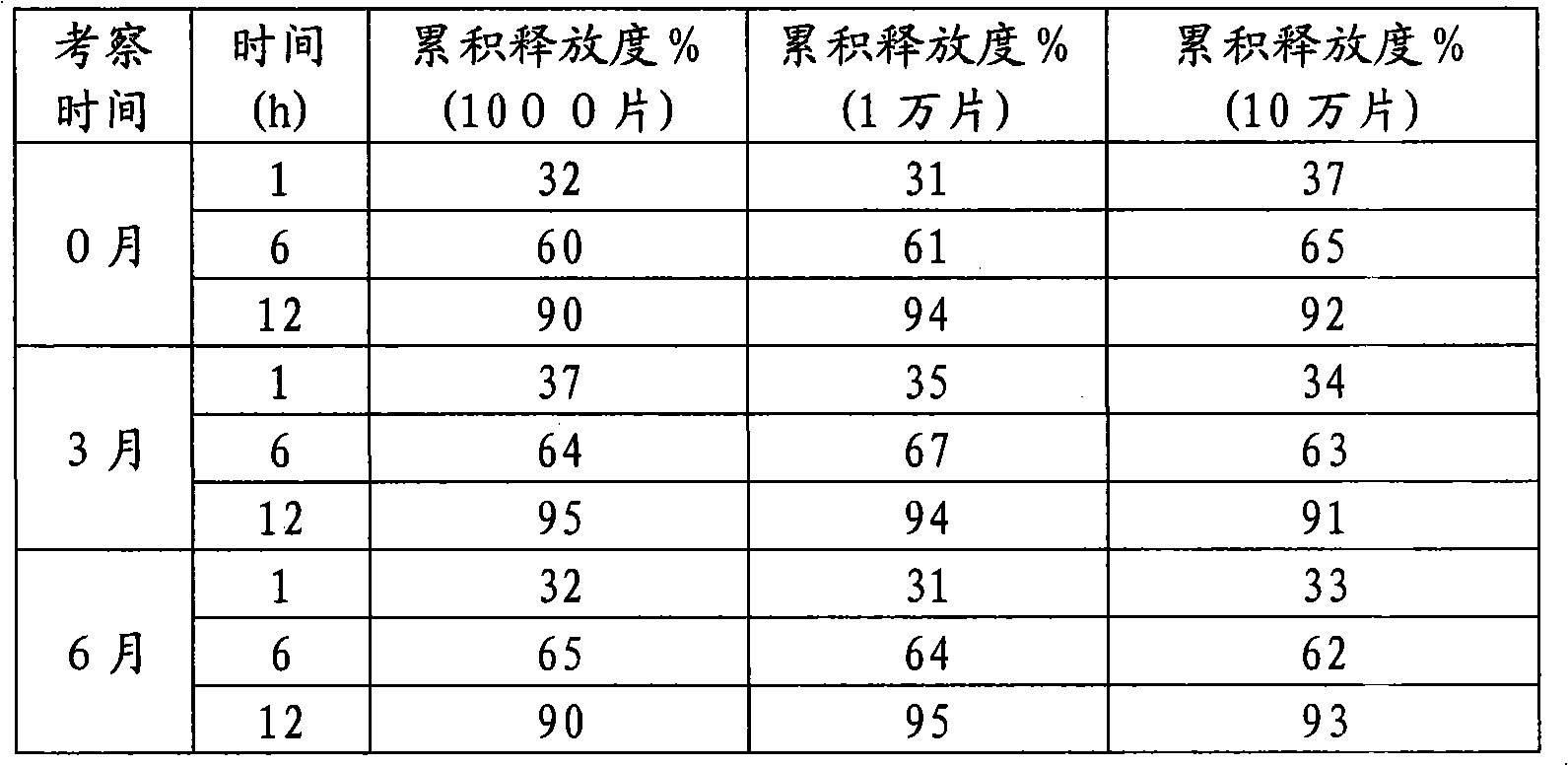

[0043] time (h)

cumulative release %

1

32

6

65

12

94

[0044] In production, according to the prescription and process, the release of 10,000 and 100,...

Embodiment 3

[0050] 1. Prescription:

[0051] Mosapride citrate

15g

HPMC K4M

30g

HPMC K15M

10g

20g

20g

70% ethanol solution

Appropriate amount

2g

Opadry

3g

A total of 1000 pieces were made

[0052] 2. Process steps:

[0053] Take mosapride citrate, crush it and pass through a 100-mesh sieve, mix it with HPMCK4M, HPMCK15M, microcrystalline cellulose and lactose, etc., wet it with 70% ethanol and granulate it, dry it at 50°C and granulate it, add Magnesium stearate, mixed evenly, pressed into tablets, coated with Opadry. The release measurement results are as follows:

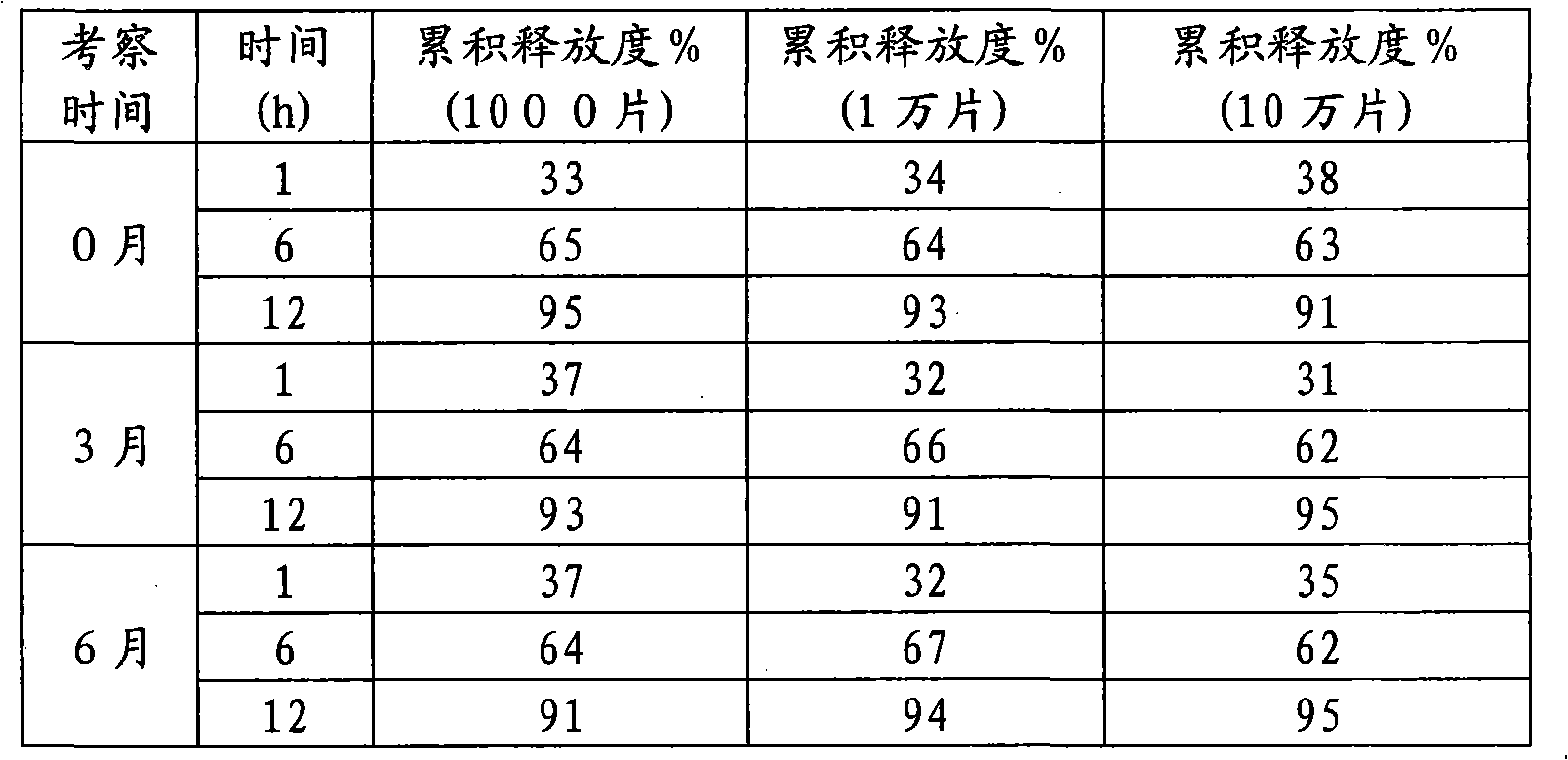

[0054] time (h)

cumulative release %

1

35

6

60

12

95

[0055] In production, according to the prescription and process, the release of 10,000 and 100,000 samples of samples is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com