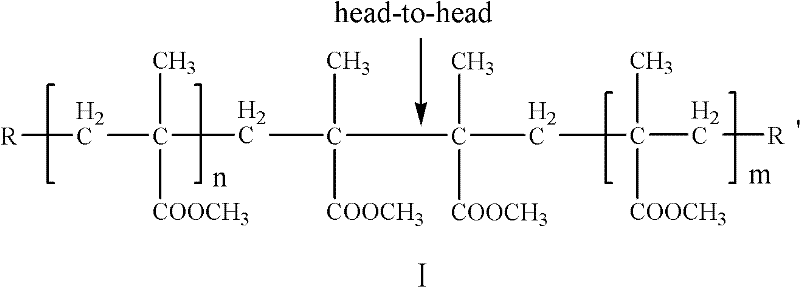

Preparation method for polymethyl methacrylate (PMMA) resin with high thermal stability

A technology of polymethyl methacrylate and methyl methacrylate, which is applied in the field of preparation of high thermal stability polymethyl methacrylate resin, can solve the problems of harsh operating conditions, exceeding 300°C, and insufficient effects, etc. Achieve high thermal degradation resistance and improve thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 A kind of preparation method of methyl methacrylate polymer (PMMA) with high thermal stability adopts continuous bulk polymerization, and steps and conditions are as follows:

[0035] A brief description of the main devices is as follows: Polymerization reactor: 10 liters, SUS304, equipped with a ribbon-type stirring paddle, a heating jacket and a built-in gas phase condenser. Devolatilization extruder: counter-rotating twin-screw extruder manufactured by Nanjing Yuesheng, with a screw diameter of 30mm and a barrel length of 2400mm. It is divided into 3 temperature control zones, and each temperature zone has 2 devolatilization ports.

[0036] The methyl methacrylate of 100 parts by weight, the initiator di-tert-butyl peroxide of 0.04 parts by weight and the chain transfer agent n-dodecyl mercaptan of 0.09 parts by weight are mixed, blow into nitrogen in the mixture to remove soluble Oxygen therein; Then, 6kg of this solution is added to 10 liters of SUS304...

Embodiment 2 to 10

[0039] Embodiment 2 to 10, condition is as table 1 and table 2; All the other are with embodiment 1.

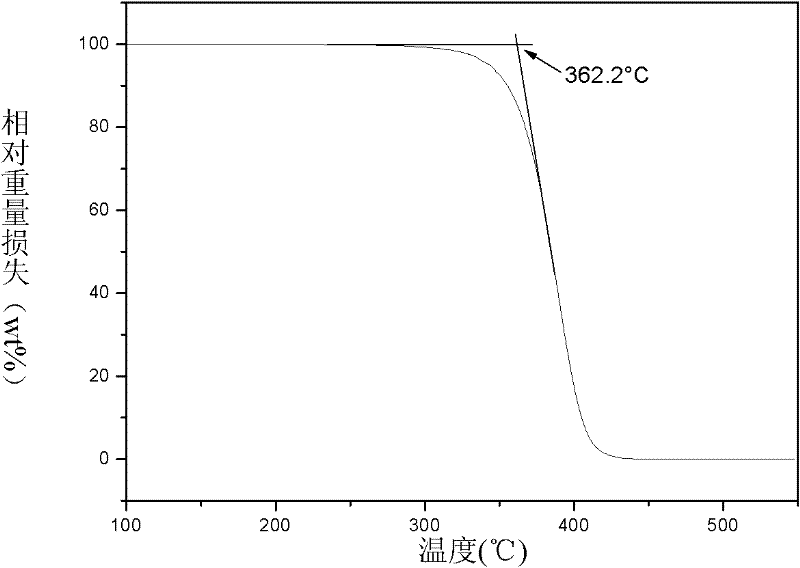

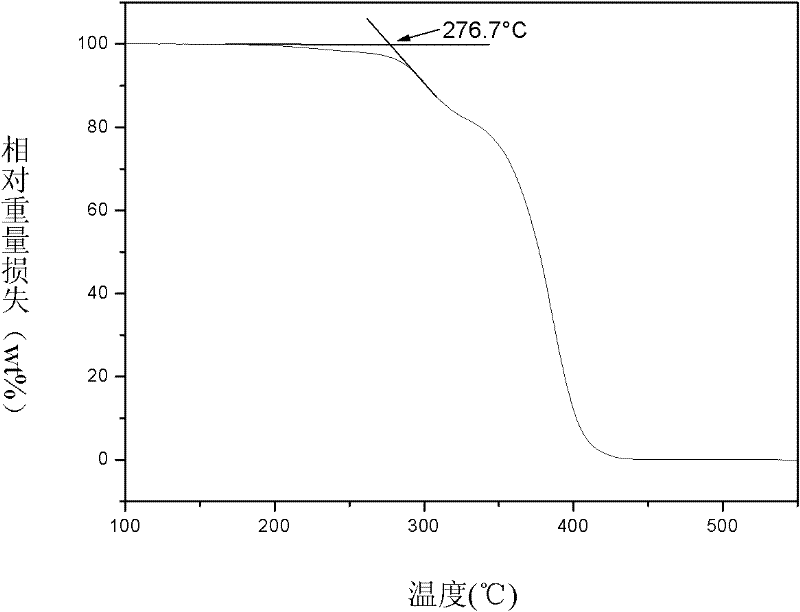

[0040] Tables 4 and 5 show the residual volatile components, weight average molecular weight, molecular weight distribution, light transmittance and initial thermal degradation temperature in the polymer pellets after devolatilization treatment.

[0041] Examples 11-15 are a preparation method of a highly thermally stable methyl methacrylate polymer (PMMA), using solution polymerization, the conditions and steps are as shown in Table 3; the rest are the same as in Example 1.

[0042] Table 6 shows the residual volatile components, weight average molecular weight, molecular weight distribution, light transmittance and initial thermal degradation temperature in the polymer pellets after devolatilization treatment.

[0043] Table 1

[0044]

[0045]

[0046] The meanings of the abbreviations in the table are as follows: (the same below); MMA is methyl methacrylate; DBP i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com