Preparation method of light-diffusion master batch

A technology of light-diffusing masterbatch and light-diffusing agent, applied in lighting and heating equipment, parts of lighting devices, lighting devices, etc., can solve the problems of uneven light transmission of PC boards, high cost, and difficulty in solving the problem of dispersion. , to achieve excellent dispersion effect, excellent heat resistance, and solve the effect of uniform light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment.

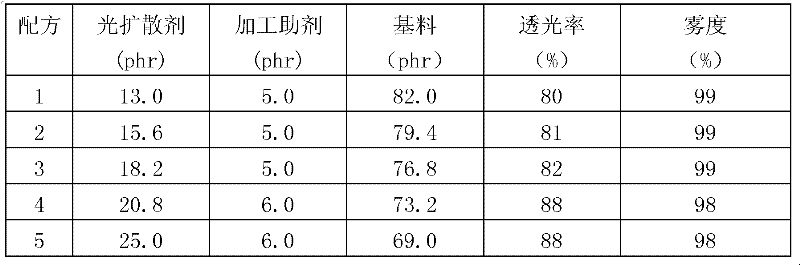

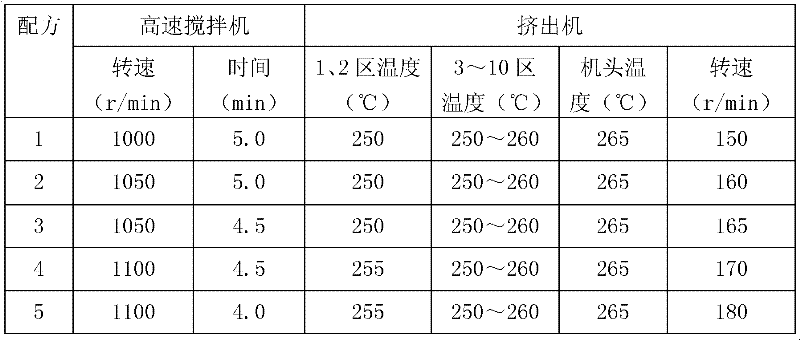

[0022] Prepare light-diffusing masterbatch according to the formula in Table 1 and the processing technology in Table 2 respectively:

[0023] Table 1 prepares the composition ratio of the light-diffusing masterbatch

[0024]

[0025] Table 2 Production process for preparing light-diffusing masterbatch

[0026]

[0027] Note: 1. Prepare the light diffusion masterbatch according to the above formula and process, and mix the prepared masterbatch and material (polycarbonate) according to the weight ratio of 1:25 to prepare the finished product. The test results of the finished product (thickness 2mm) are shown in the table The light transmittance and haze in 1; as can be seen from Table 1, when the weight percentage of light diffusing agent is 20.8~25%, the weight percentage of processing aid is 6%, and the weight percentage of base resin is 73.2~25%. 69%, the prepared masterbat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com