Method for preparing high temperature retarding-type organic boron zirconium cross linking agent

A cross-linking agent and organic technology, which is applied in the field of preparation of high-temperature delayed organic boron-zirconium cross-linking agent, can solve the problems of cost increase, friction reduction, fracturing fluid friction increase and residue, etc., to improve production capacity, Improve the diversion capacity and improve the effect of fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) Prepare a composite solvent: mix glycerol and water in a mass ratio of 1:3, and stir to obtain a composite solvent;

[0016] 2) Add 74 parts of composite solvent and 2 parts of zirconium tetrachloride to a clean flask in parts by mass, stir until completely dissolved, then add 13 parts of boric acid, and react at 60°C for 40 minutes to obtain a mixture;

[0017] 3) Add 13 parts of sorbitol, 4 parts of triethanolamine and 0.1 part of EDTA-2Na to the mixture obtained in step 2), raise the temperature to 80° C., and react for 4 hours;

[0018] 4) Adjust the pH to 7 with NaOH aqueous solution to obtain an organoboron-zirconium crosslinking agent.

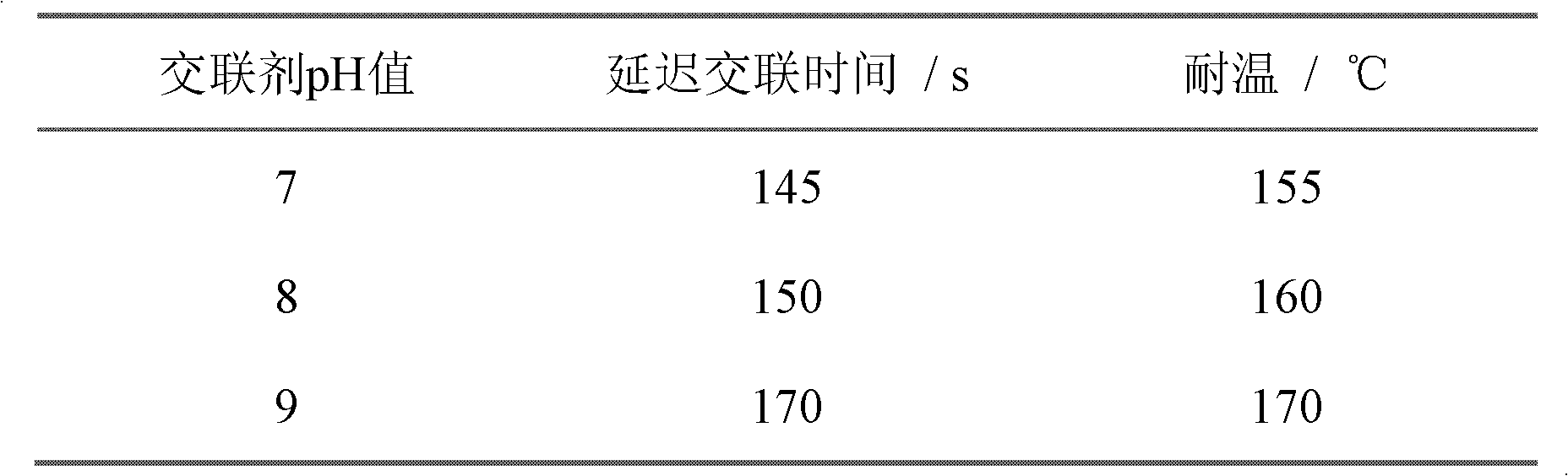

[0019] After testing, the delayed crosslinking time and temperature resistance of the jelly obtained by crosslinking the organic boron zirconium crosslinking agent prepared in this example with 100mL0.5% guar gum aqueous solution at a concentration of 0.3% are as follows:

[0020]

Embodiment 2

[0022] 1) Prepare composite solvent: mix glycerol and water in a mass ratio of 1:5, and stir to obtain a composite solvent;

[0023] 2) Add 76 parts of composite solvent and 3 parts of zirconium oxychloride to a clean flask in parts by mass, stir until completely dissolved, then add 11 parts of borax, and react at 60°C for 60 minutes to obtain a mixture;

[0024] 3) Add 12 parts of mannitol, 4.3 parts of triethanolamine and 0.2 parts of EDTA-2Na to the mixture obtained in step 2), raise the temperature to 80° C., and react for 5 hours;

[0025] 4) Adjust the pH to 8 with NaOH aqueous solution to obtain an organoboron-zirconium crosslinking agent.

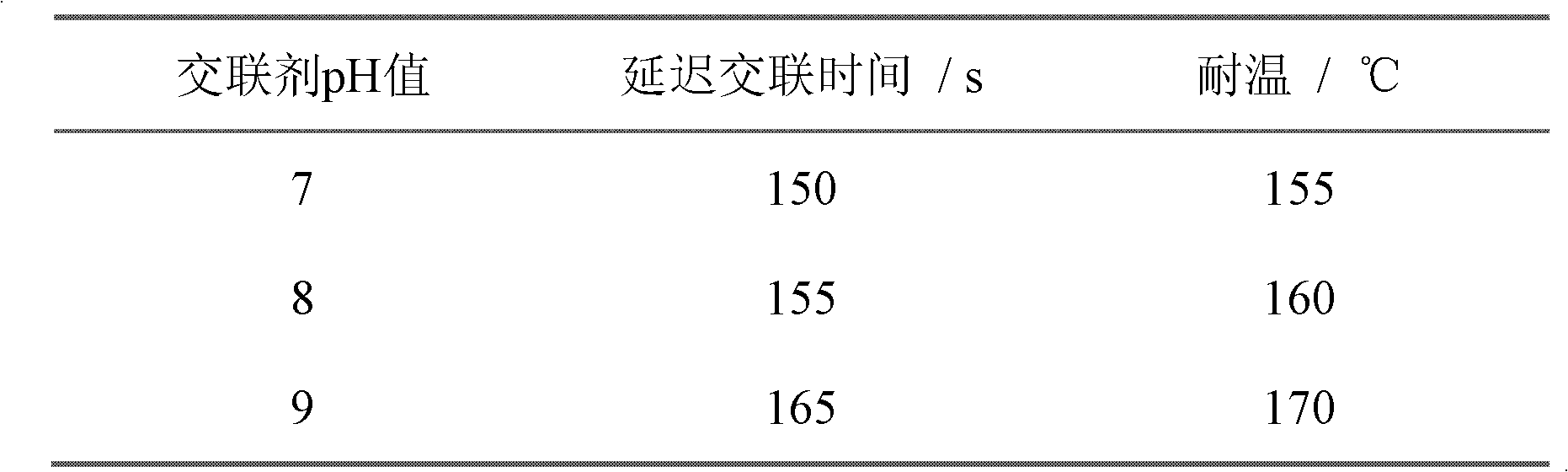

[0026] After testing, the delayed crosslinking time and temperature resistance of the jelly obtained by crosslinking the organoboron zirconium crosslinking agent prepared in this example with 100mL0.4% guar gum aqueous solution at a concentration of 0.3% are as follows:

[0027]

Embodiment 3

[0029] 1) Prepare a composite solvent: mix glycerol and water in a mass ratio of 1:4, and stir to obtain a composite solvent;

[0030] 2) Add 80 parts of composite solvent and 1 part of zirconium tetrachloride to a clean flask in parts by mass, stir until completely dissolved, then add 15 parts of a mixture of boron compound boric acid and borax, and react at 60°C 30min to get the mixture;

[0031] 3) Add 14 parts of sorbitol, 4.5 parts of triethanolamine and 0.15 parts of EDTA-2Na to the mixture obtained in step 2), raise the temperature to 80° C., and react for 4.5 hours;

[0032] 4) Adjust the pH to 9 with NaOH aqueous solution to obtain an organoboron-zirconium crosslinking agent.

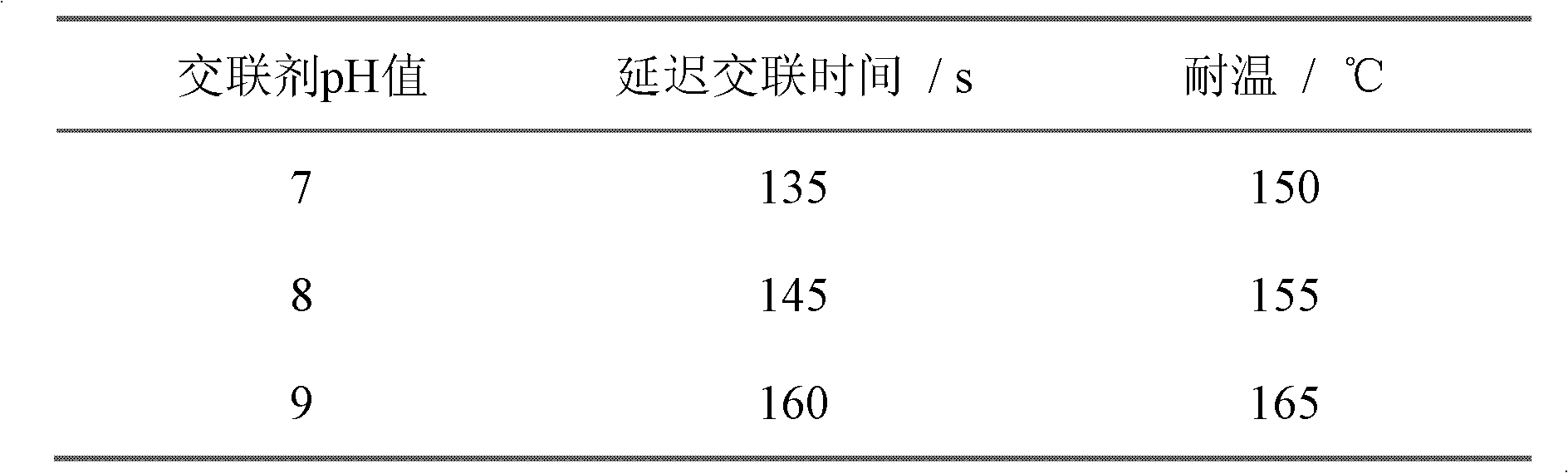

[0033] After testing, the delayed crosslinking time and temperature resistance of the jelly obtained by crosslinking the organoboron zirconium crosslinking agent prepared in this example with 100mL0.35% guar gum aqueous solution at a concentration of 0.3% are as follows:

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com